Reinforced control cable

A control cable, reinforced technology, applied in the direction of insulated cables, communication cables, bendable cables, etc., can solve the problems of insufficient endurance, short circuit of communication lines, easy cracking, etc., to achieve strong flexibility, reasonable and simple structure, Easy to produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

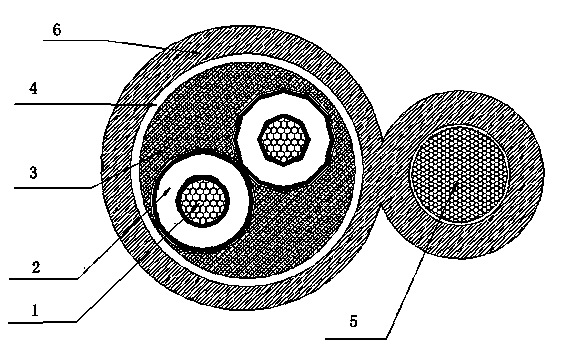

[0011] Such as figure 1 As shown, a reinforced control cable of the present invention includes a cable core and an outer sheath 6, and the cross section of the outer sheath 6 is integrated by a circular large end and a circular small end, The cable core twisted by two insulated wire cores is wrapped in the large end of the outer sheath 6, and the filling layer 3 is provided in the gap of the cable core, and the shielding layer 4 is wrapped around the cable core; there is also an outer sheath A reinforcing steel wire 5 is arranged in the small end of 6, and the reinforcing steel wire 5 is arranged in parallel with the cable core. The insulated wire core is composed of a conductor 1 which is multi-stranded oxygen-free copper wire and an insulating layer 2 which is extruded outside the conductor 1 and adopts radiation cross-linked or silane cross-linked polyethylene insulating material.

[0012] The thickness of the insulating layer 2 mentioned above is 0.8 mm, and the thickness of

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap