Plastic wire former

A technology of filament forming machine and plastic filament, which is applied in the direction of filament generation, textile and paper making, etc. It can solve problems such as waste products, plastic filament bonding, and affecting product quality, so as to ensure product quality, prevent plastic filament bonding, reduce The effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0009] The present invention will be further described below in conjunction with the drawings.

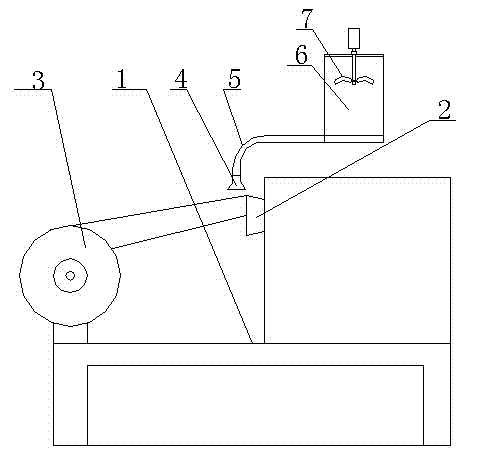

[0010] Such as figure 1 As shown, the plastic filament forming machine includes a forming machine main body 1. The forming machine main body has a plastic wire outlet head 2 and a take-up wheel 3, which is characterized in that: a steam nozzle 4 is provided on the outlet head. The outlet of the nozzle faces the thread-out head and sprays downward. In this way, when the plastic wire comes out, water vapor will diffuse on the plastic wire and it will not stick.

[0011] Furthermore, the steam spray head is connected to a pool 6 with a pipe 5, and a stirring device 7 is provided on the pool. When in use, place talcum powder in the pool, so that the sprayed plastic filament will have talcum powder, which can reduce the adhesion of the plastic filament.

[0012] The above are only specific embodiments of the present invention, but the structural features of the present invention are not limite

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap