Automatic packing and weighing method and system for welding strips

An automatic packaging and weighing system technology, applied in the field of welding strips, can solve the problems of heavy workload, easy marking errors, waste of working hours, etc., and achieve the effect of saving labor, improving accuracy and traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0047] Example 1

[0048] This embodiment provides an automatic packaging and weighing method and system for welding ribbons, which are used in the manufacturing process of photovoltaic ribbons.

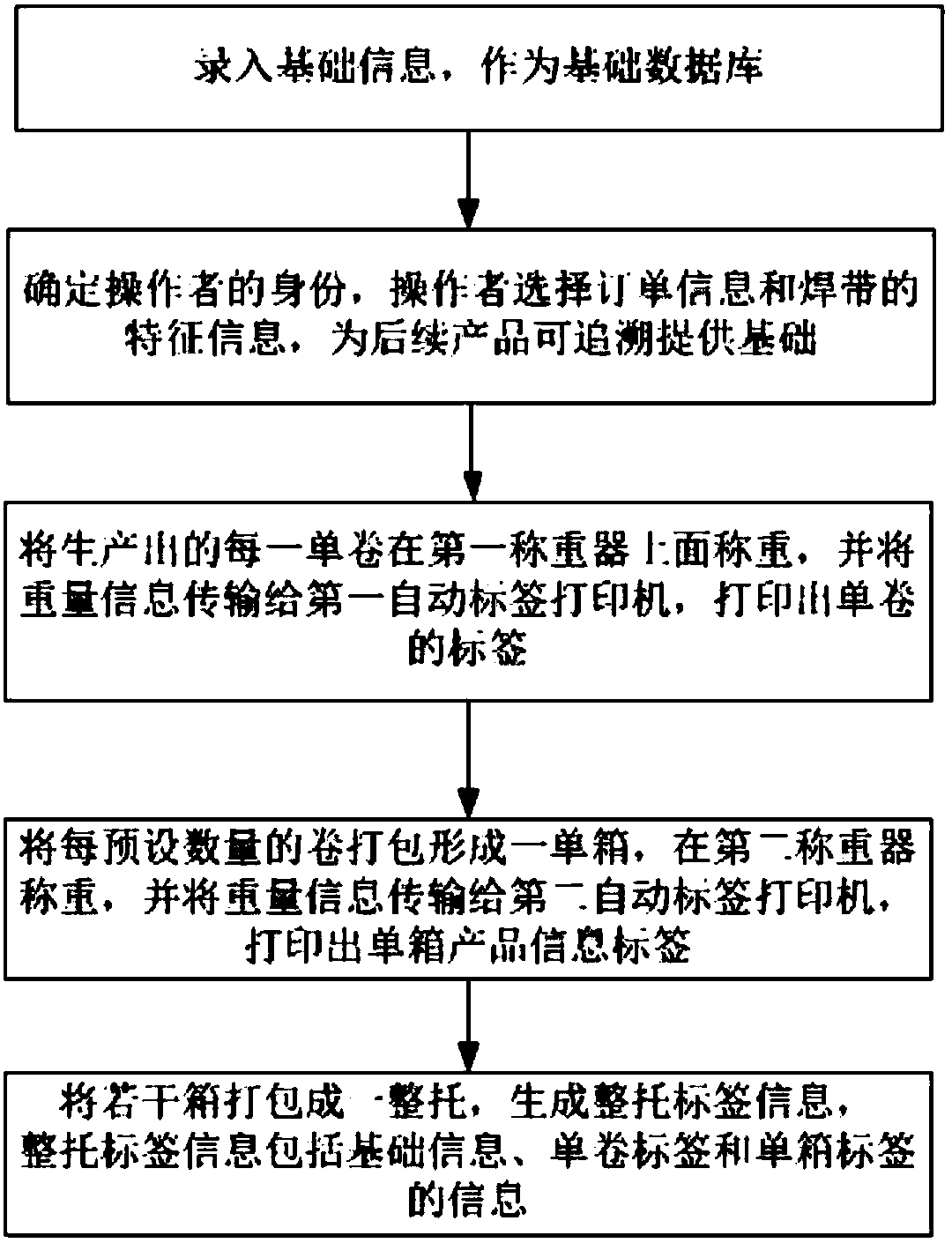

[0049] Specifically, such as figure 1 , figure 2 As shown, a welding tape automatic packaging and weighing method includes:

[0050] Enter basic information as a basic database;

[0051] Determine the identity of the operator, and the operator selects the order information and the characteristic information of the welding ribbon, which provides a basis for the traceability of subsequent products;

[0052] Weigh each single roll produced on the first weigher 500, and transmit the weight information to the first automatic label printer 300 to print out the single roll of labels;

[0053] Pack each preset number of rolls into a single box, weigh it on the second weigher 600, and transmit the weight information to the second automatic label printer 400 to print out the single box product information

Example Embodiment

[0062] Example 2

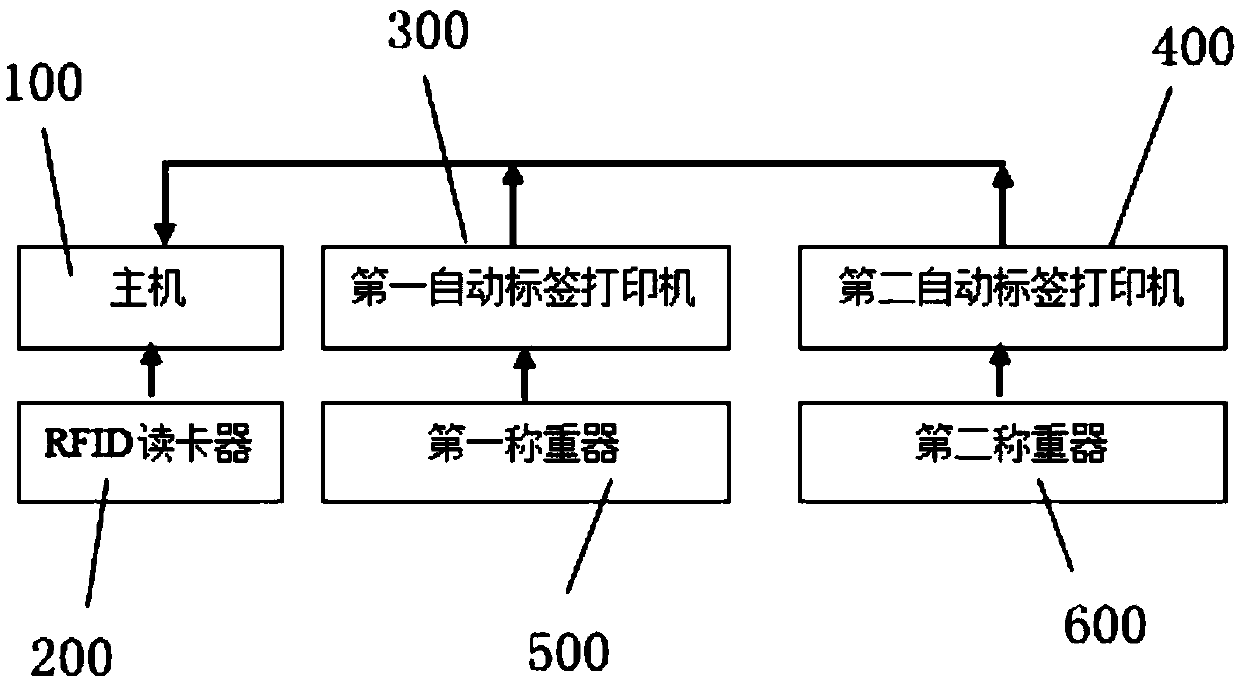

[0063] This embodiment also provides a welding tape automatic packaging and weighing system, such as figure 2 Shown, including:

[0064] Basic data module (not shown in the figure), used to enter basic information, as a basic database;

[0065] The order processing module is used to determine the identity of the operator. The operator selects the order information and the characteristic information of the welding ribbon to provide a basis for the traceability of subsequent products;

[0066] The single-roll welding tape packaging weighing module is used to weigh each single-roll produced on the first weigher 500 and transmit the weight information to the first automatic label printer 300 to print out the single-roll label;

[0067] The single box welding tape packaging weighing module is used to pack each preset number of rolls into a single box, weigh it on the second scale 600, and transmit the weight information to the second automatic label printer 400, and print o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap