Observation window for missile launching vehicle

A missile launch and observation window technology, which is applied in the field of car windows, can solve the problems of unsatisfactory radar stealth ability, insufficient visible light transmission performance, and unfavorable external observation, etc., and achieve simple structure, strong anti-electromagnetic pulse ability, and improved protection performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

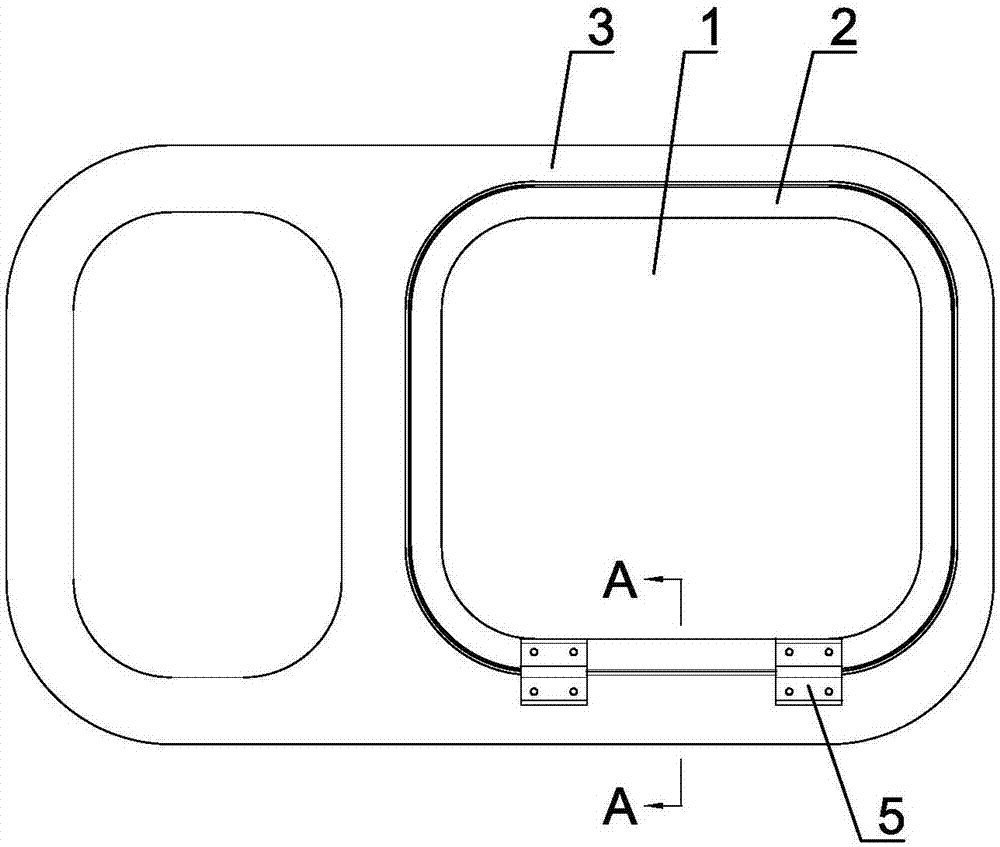

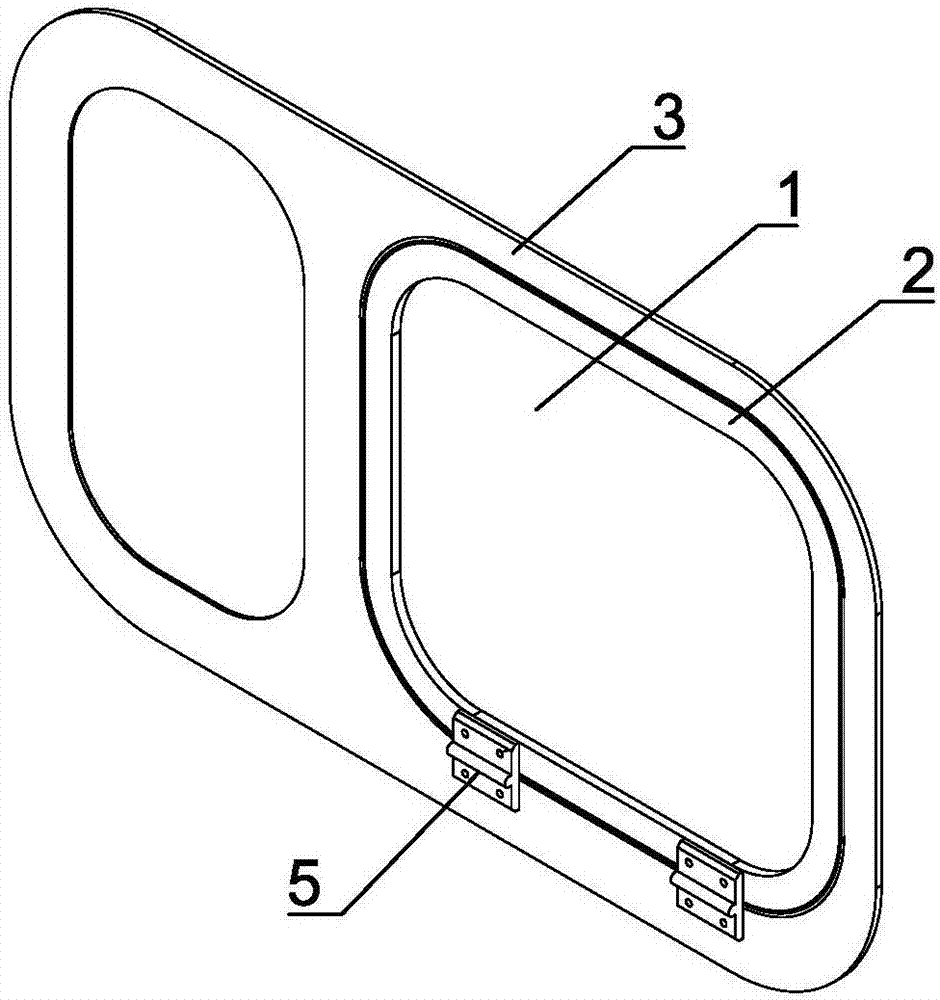

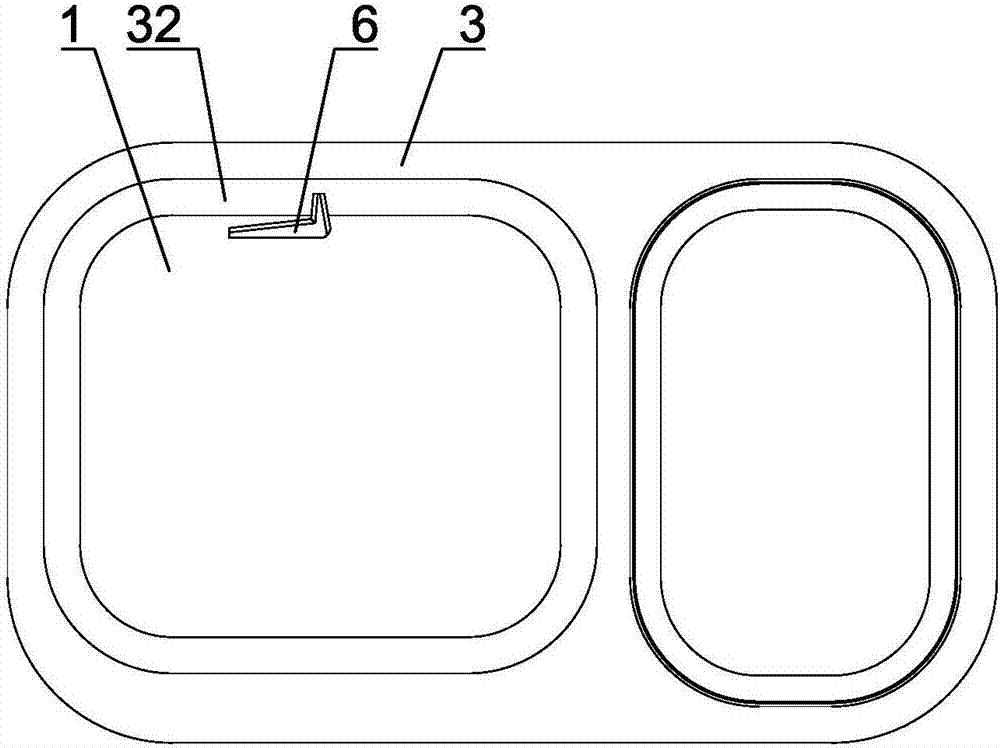

[0018] Such as Figure 1 to Figure 6 Shown is a specific embodiment of an observation window for a missile launching vehicle of the present invention, including tempered glass 1 and window frame 2 . Let the tempered glass 1 adopt a layered structure including an outer glass and an inner glass, and coat the outer surface of the outer glass with a transparent metamaterial film, coat the outer surface of the inner glass with a transparent metal film, and coat the outer surface of the inner glass with a transparent metal film. The edge is plated with silver paste, and the inner side of the inner glass is pasted with an explosion-proof film, so that the inner side of the outer glass and the outer side of the inner glass are connected by lamination. Simultaneously, let window frame 2 specifically comprise outer pressure frame 21 and inner pressure frame 22, limit ring 23 is set on the inner surface of outer pressure frame 21, allow outer pressure frame 21 and inner pressure frame 22 to

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap