Conductive paste for solar cell electrode and solar cell manufactured using same

a technology of solar cells and conductive pastes, which is applied in the direction of photovoltaic energy generation, non-conductive materials with dispersed conductive materials, semiconductor devices, etc., can solve the problems of poor reliability of printing quality characteristics, undetected deterioration of solar cells efficiency, and reduced light-receiving area, so as to improve the power generation efficiency of solar cells, increase the sintering shrinkage rate, and improve the effect of short-circuit curren

Inactive Publication Date: 2020-01-23

LS MNM INC

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

The inventors have found that adding certain metals increases the size of the back surface field for better performance at longer wavelengths. This results in improved energy conversion from sunlight into electricity by making it more efficient than traditional methods like silicon cells. Additionally, they discovered that reducing lines' resistances reduces overall voltage drop across them while also improving their ability to absorb large amounts of incident radiation during long periods of time without burning out or losing effectiveness over multiple cycles.

Problems solved by technology

This patented technical problem addressed in the patents relates to improving the performance and production rate of solar cells while reducing dark currents caused by reflection from incident sunlight onto their backs during photovoltaics conversion processes. Current methods involve adding extra layers made up of different metals to improve reflectivity without affecting absorption properties, resulting in decreased open circuit voltage and improved carrier generation efficacy. Additionally, these techniques require expensive equipment and long hours to perform multiple steps, leading to lower product yields compared to traditional methodologies.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| Shrinkage | aaaaa | aaaaa |

| Shrinkage | aaaaa | aaaaa |

| Shrinkage | aaaaa | aaaaa |

Login to view more

Abstract

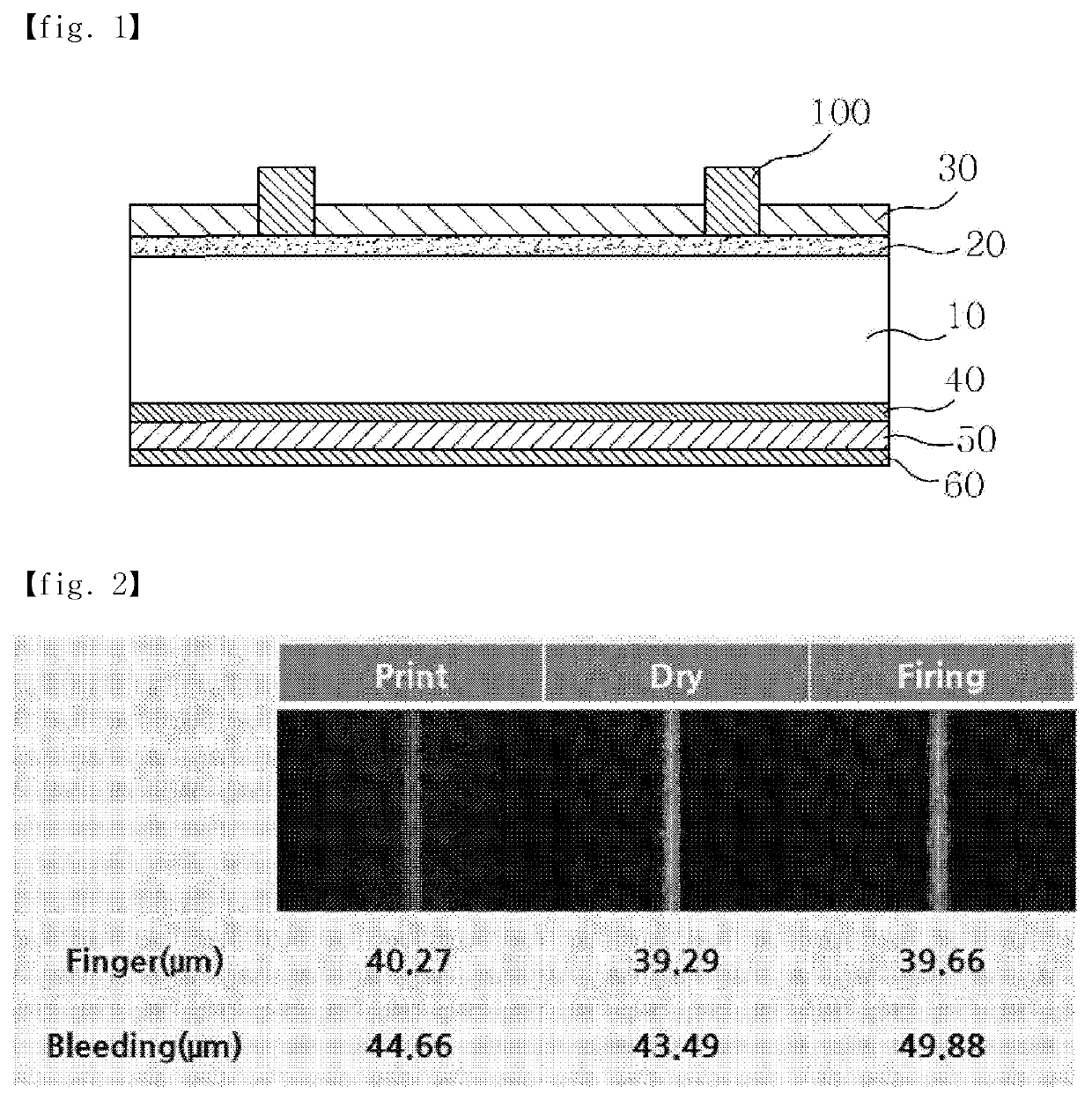

The present invention relates to a conductive paste for a solar cell electrode, including a metal powder, a glass frit and an organic vehicle, wherein the metal powder includes a metal powder having a sintering shrinkage rate of 15 to 30%, whereby the light-receiving area of the front electrode of a solar cell formed using the conductive paste including the metal powder having an increased sintering shrinkage rate can be enlarged and short-circuit current (Isc) can be increased, thus increasing the power generation efficiency of the solar cell.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Owner LS MNM INC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap