Pressurizing shaping and high-temperature aging integrated device for battery production and use method thereof

A high-temperature aging, battery technology, applied in lithium batteries, battery assembly machines, secondary battery manufacturing, etc., can solve the problems of inaccurate testing, increase labor intensity of workers, reduce battery production efficiency, etc., to shorten positioning time and improve production. Efficiency, the effect of improving the leveling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

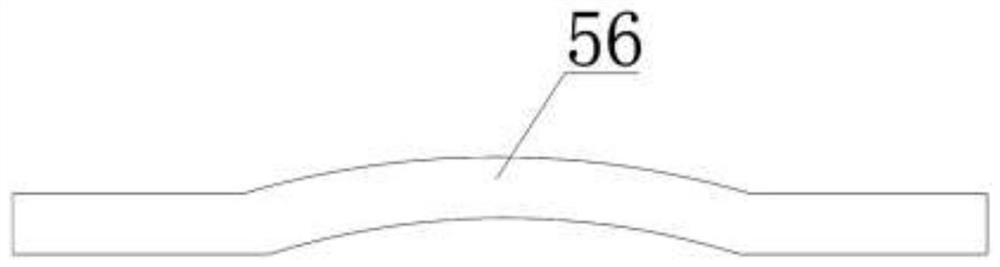

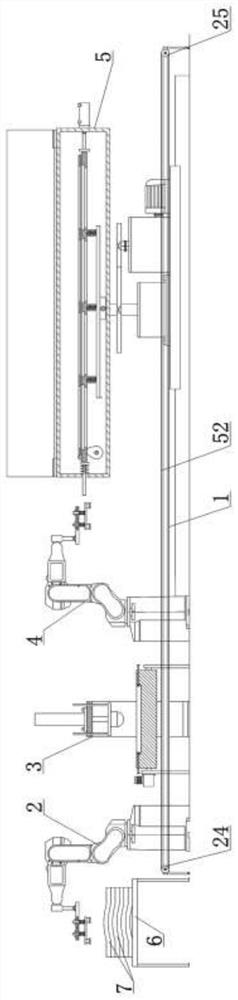

[0056] Such as Figure 3~12 As shown, the integrated pressurized shaping and high-temperature aging device for battery production includes a first robot arm 2, a shaping device 3, and a second robot arm arranged on the rear side of the flat belt conveyor 1 and arranged in sequence from left to right. 4 and the high temperature aging device 5 and the material platform 6 arranged on the left side of the flat belt conveying device 1, on which a plurality of semi-finished batteries 7 are stacked; the flat belt conveying device 1 includes a frame 23 fixed on the ground , the driven roller 24 and the driving roller 25 that are installed in the left and right ends of the frame 23 in rotation, the flat belt 52 is installed between the driving roller 25 and the driven roller 24, the servo motor 26 is fixed on th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap