Rare-earth-doped nitrogen oxide green fluorescent powder and preparation method thereof

A technology of green fluorescent powder and nitrogen oxides, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve problems such as gaps, achieve stable physical and chemical properties, reduce reaction conditions and costs, and have a wide range of effective excitation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

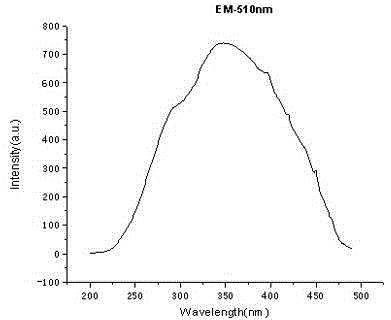

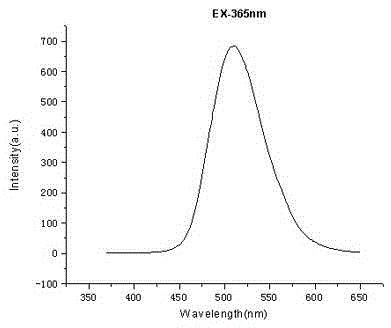

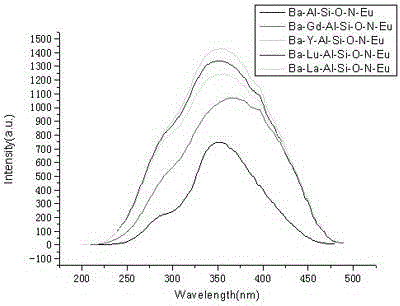

[0022] Example 1: According to Ba 0.9 Y 0.1 Al 1.3 Si 0.6 o 3.4 N 0.6 :0.1Eu 2+ Chemical formula, weigh BaCO 3 2.7323g, Al 2 o 3 1.0196g, SiO 2 0.1386g, Y 2 o 3 0.1737g, Eu 2 o 3 0.2707g, BaCO 3 , SiO 2 All are analytically pure, Y 2 o 3 、Eu 2 o 3 The purity is 4N and above, and 5% flux NH is added 4 After F 0.2329g is mixed and ground evenly, put it into a high-temperature furnace, heat evenly from room temperature to 1250°C, keep it warm for 3 hours, then take it out after naturally cooling to room temperature, and add Si 3 N 4 0.3237g is fully ground, placed in N 2 / H 2 =10:1 atmosphere furnace at 1200 ° C for 6 hours. Cool to room temperature under a nitrogen atmosphere. Wash the product with deionized water at 60°C for 2-3 times, and dry it at 120°C to obtain rare earth-doped green phosphor powder Ba 0.9 Y 0.1 Al 1.3 Si 0.6 o 3.4 N 0.6 :0.1Eu 2+ (i.e. x=0.1, y=0.1, z=0.6). Its excitation spectrum has a wide excitation peak, and the exc

Embodiment 2— Embodiment 7

[0024] Except for weighing the raw materials according to the chemical formula composition and stoichiometry of each embodiment in Table 1, the rest of the manufacturing steps are the same as in Example 1, and the chemical composition, color coordinates, and relative brightness are shown in Table 1.

[0025] Table 1 Chemical formulas of Examples 1-6 and their color coordinates and relative brightness

[0026] Example chemical formula Color coordinates (x,y) relative brightness 1 Ba 0.9 Y 0.1 Al 1.3 Si 0.6 o 3.4 N 0.6 :0.1Eu 2+ (0.1861,0.5662) 1.842 2 Ba 0.9 Y 0.05 Al 1.35 Si 0.6 o 3.4 N 0.6 :0.1Eu 2+ (0.1876,0.5723) 1.757 3 Ba 0.9 Y 0.3 Al 1.1 Si 0.6 o 3.4 N 0.6 :0.1Eu 2+ (0.1858,0.5652) 2.454 4 Ba 0.9 Y 0.325 Al 1.075 Si 0.6 o 3.4 N 0.6 :0.1Eu 2+ (0.1832,0.5656) 2.479 5 Ba 0.9 Y 0.35 Al 1.05 Si 0.6 o 3.4 N 0.6 :0.1Eu 2+ (0.1823,0.5658) 2.734 6 Ba 0.9 Y 0

Embodiment 8

[0027] Example 8: According to Ba 0.9 Lu 0.1 Al 1.3 Si 0.6 o 3.4 N 0.6 :0.1Eu 2+ Chemical formula, weigh BaCO 3 2.7323g, Al 2 o 3 1.0196g, SiO 2 0.1387g, Lu(OH) 3 0.0.3477g, Eu(OH) 3 0.3123g, BaCO 3 , SiO 2 All are analytically pure, Y 2 o 3 、Eu 2 o 3 The purity is 4N and above, and 10% flux NH is added 4 After F 0. 4874g is mixed and ground evenly, put it into a high-temperature furnace, heat it uniformly from room temperature to 1250°C, keep it warm for 3 hours, then cool it down to room temperature naturally and grind it, then mix the powder with a certain proportion of Si 3 N 4 0.3237g is fully ground, placed in N 2 / H 2 =10:1 atmosphere furnace at 1200 ° C for 6 hours. Cool to room temperature under a nitrogen atmosphere. Wash the product with deionized water at 60°C for 2-3 times, and dry it at 120°C to obtain rare earth-doped green phosphor powder Ba 0.9 Lu 0.1 Al 1.3 Si 0.6 o 3.4 N 0.6 :0.1Eu 2+ (i.e. x=0.1, y=0.1, z=0.6). with standa

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap