Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Zinc sulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc sulfide (or zinc sulphide) is an inorganic compound with the chemical formula of ZnS. This is the main form of zinc found in nature, where it mainly occurs as the mineral sphalerite. Although this mineral is usually black because of various impurities, the pure material is white, and it is widely used as a pigment. In its dense synthetic form, zinc sulfide can be transparent, and it is used as a window for visible optics and infrared optics.

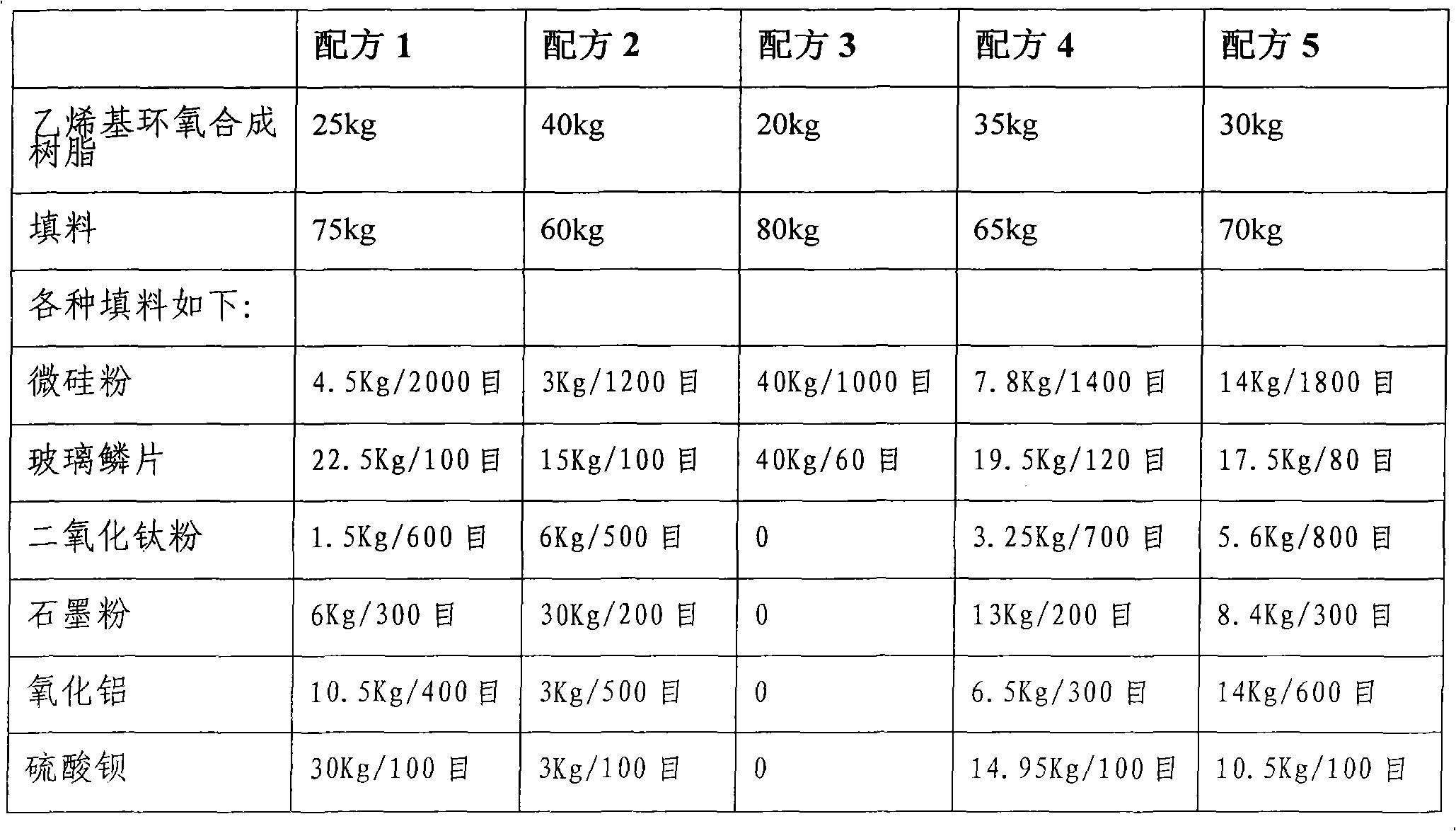

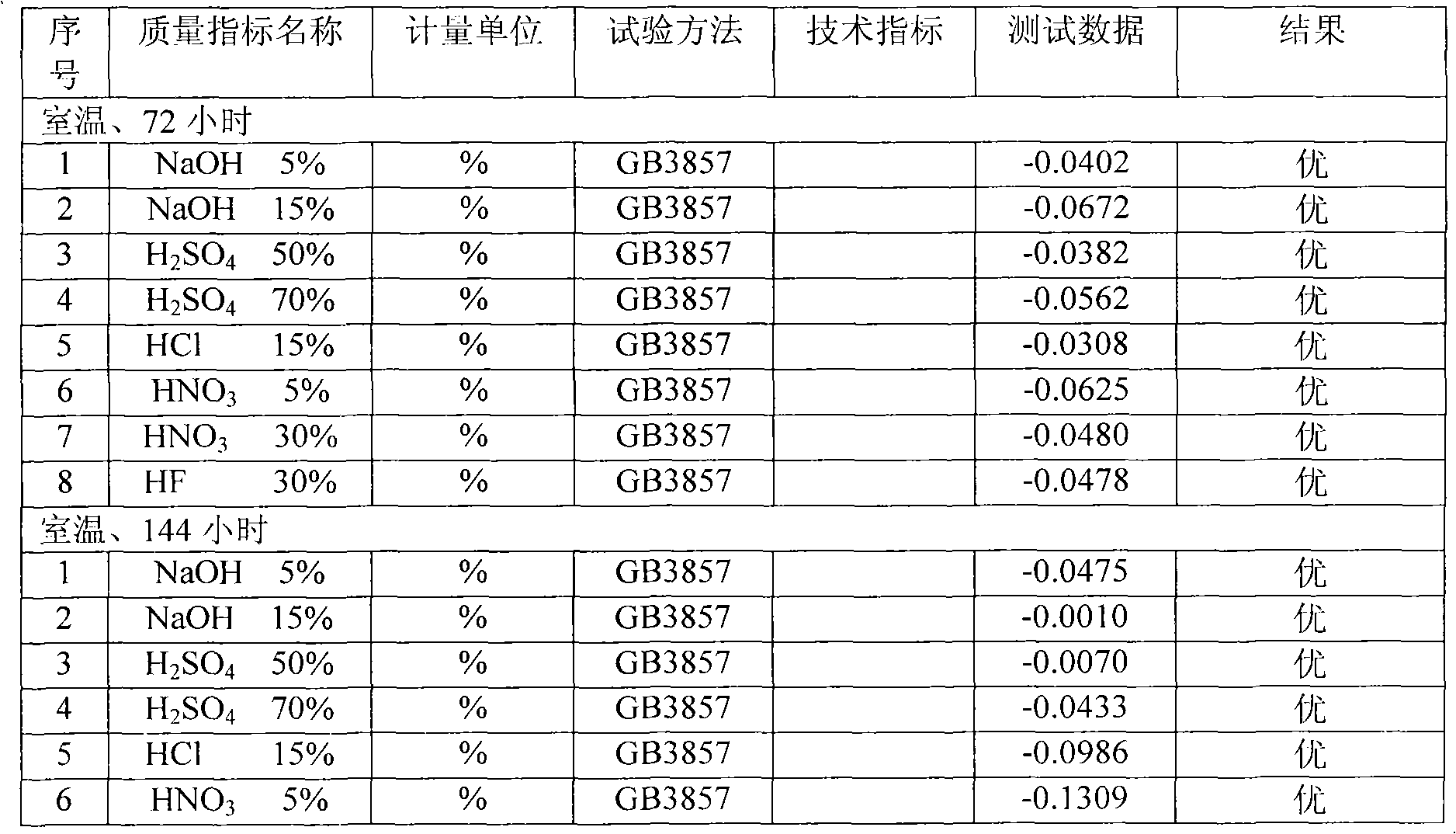

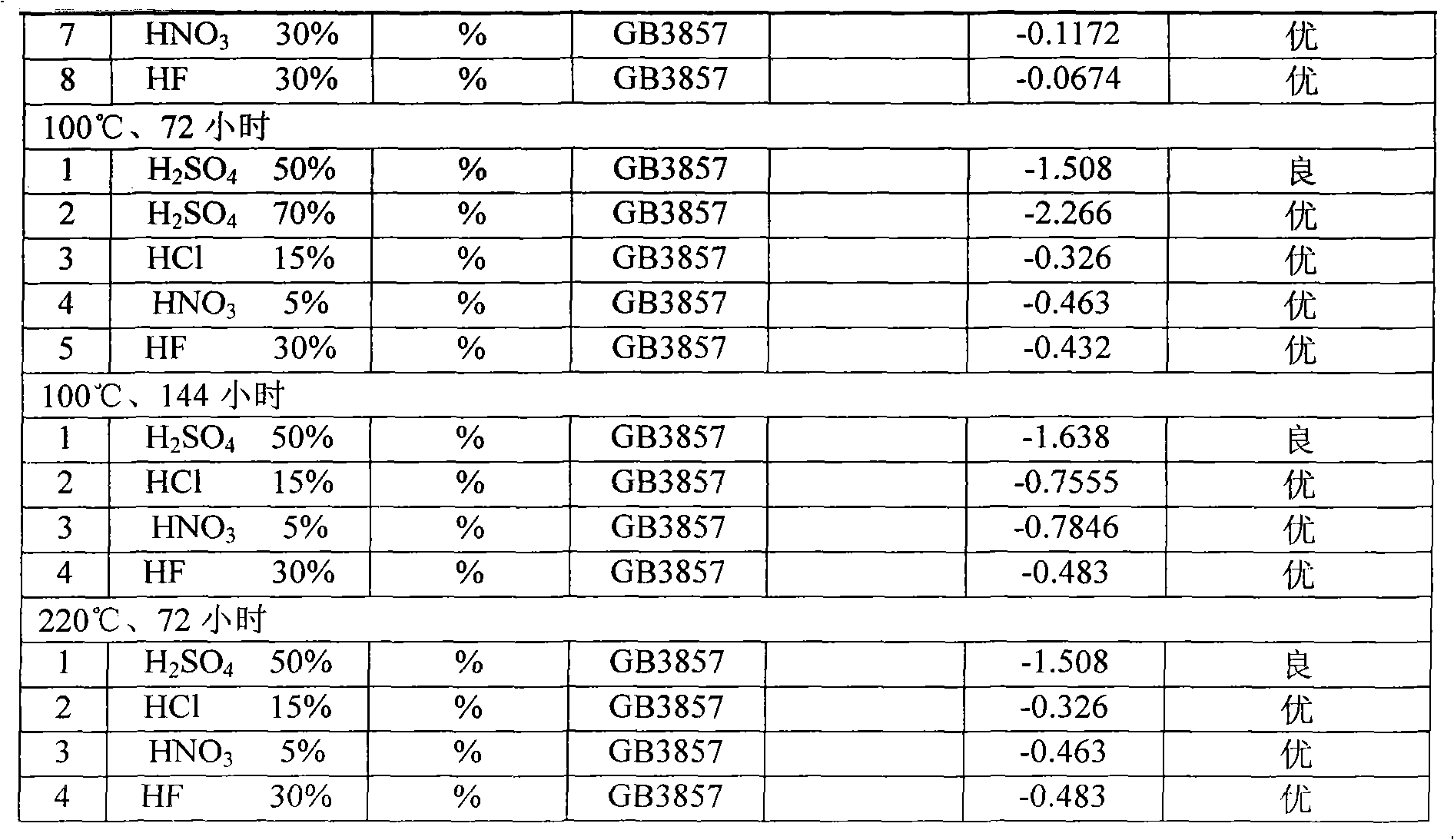

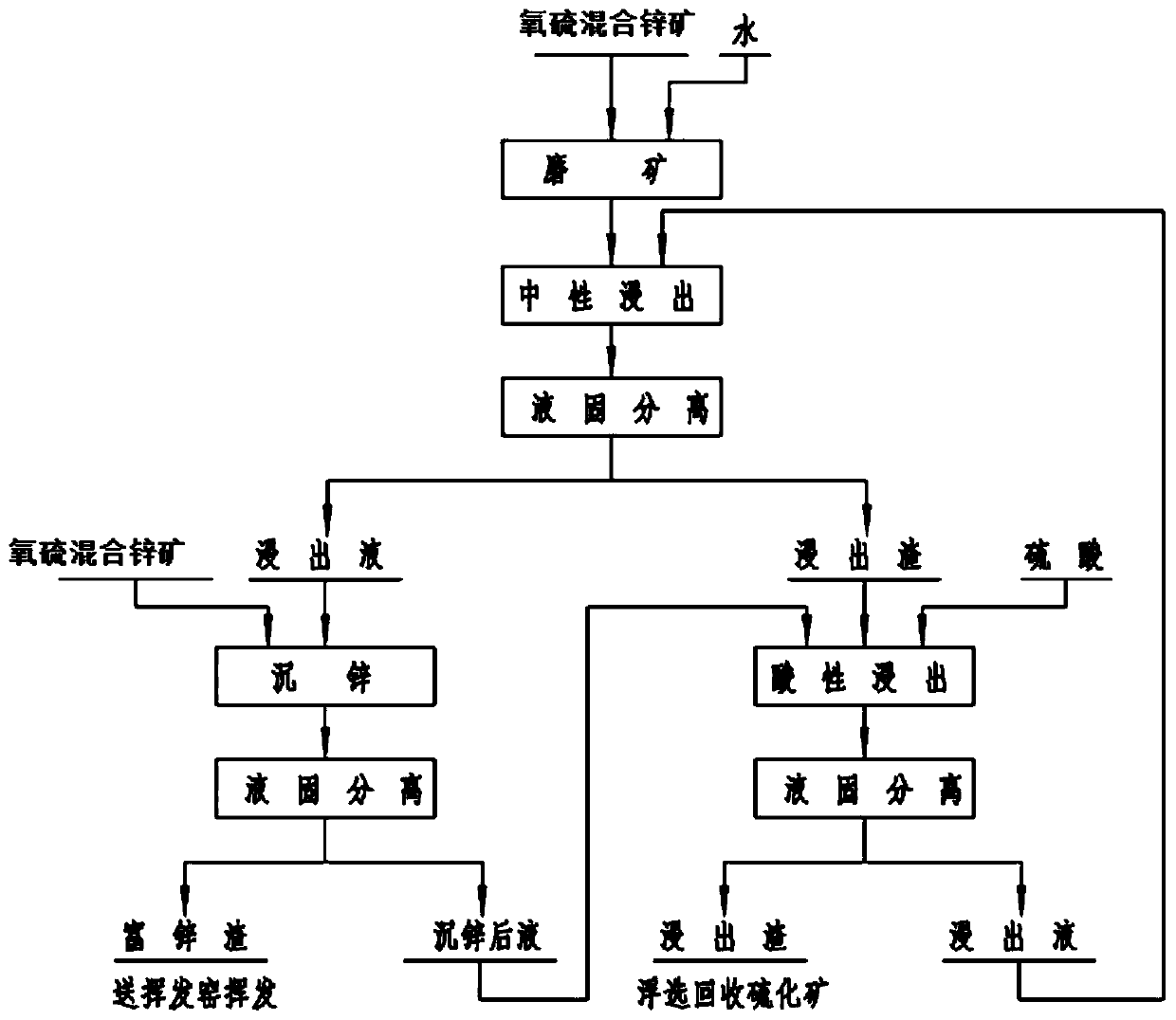

Method for secondarily enriching zinc from low-grade high-oxidization-rate oxygen-sulfur mixed zinc ore

ActiveCN110157924AImprove leaching efficiencyImprove leaching rateProcess efficiency improvementPregnant leach solutionSulfur

Owner:CINF ENG CO LTD

Low-temperature sputtering graphene transparent electrode thin-film solar cell

PendingCN114497249A'Chemical composition optimizationOptimize chemical compositionVacuum evaporation coatingSputtering coatingSolar cellMaterials science

The invention provides a low-temperature sputtering graphene transparent electrode thin-film solar cell, which is applied to the technical field of solar cells, and is characterized in that a molybdenum thin film with the thickness of about 0.35-1.0 micron is plated on a soda-lime glass substrate or a flexible substrate with sodium, and a photovoltaic'copper-zinc-tin-selenium 'thin film layer with the thickness of about 0.7-1.5 microns or the standard thickness of 1.0 micron is plated on the molybdenum thin film; plating a p-n junction film on the upper surface of the copper-zinc-tin-selenium film layer; cadmium sulfide or zinc sulfide with the thickness of 0.05 micron is plated on the copper-zinc-tin-selenium thin film and the crystal; plating an insulating layer zinc oxide with the thickness of about 0.1 micron on the cadmium sulfide or the zinc sulfide; plating a graphene transparent conductive film with the thickness of about 0.35-1.9 microns on the zinc oxide as a front electrode, plating nickel with the thickness of about 0.05 microns on the front electrode, and plating an aluminum film with the thickness of about 3.0 microns on the nickel; plating a layer of protective nickel with the thickness of about 0.05 micron on the aluminum film; a soda-lime cover glass or other flexible cover layer having a thickness of about 1.0 to 4.0 mm is placed on the protective nickel.

Owner:项芳利

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap