Manufacturing process of rubber product production equipment

A technology for production equipment and rubber products, applied in the field of rubber product production equipment, can solve problems such as deformation and normal production, and achieve the effects of high efficiency, small equipment footprint and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

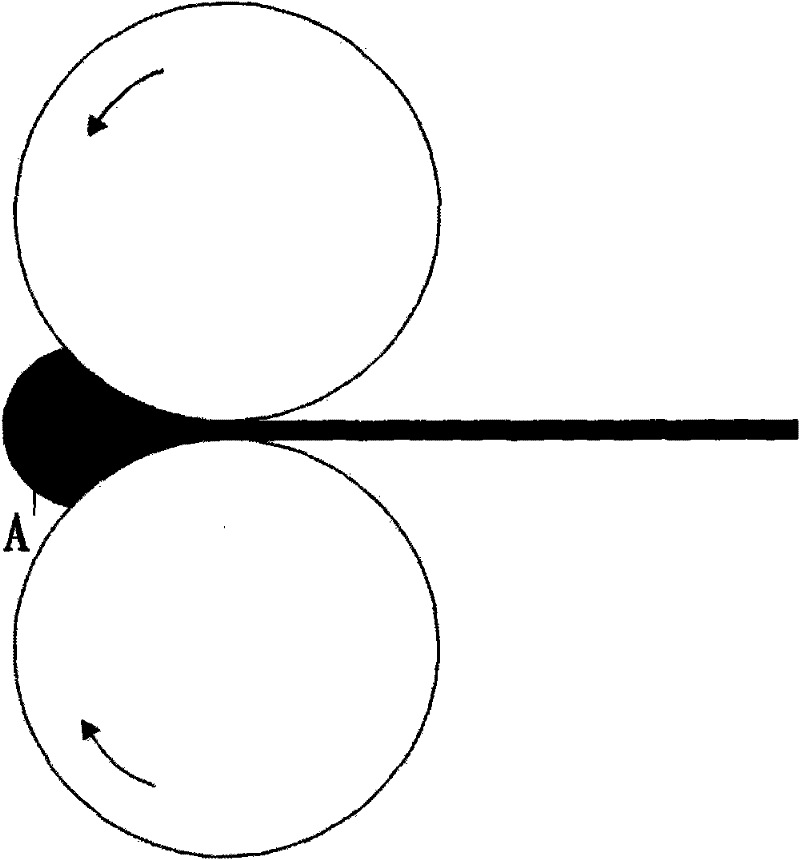

[0043] The products produced by the present invention are greatly affected by the viscosity and plasticity of rubber, especially for rubber with high viscosity and low Mooney viscosity (such as silicone rubber), rubber sheets cannot be produced, and only low viscosity and high Mooney viscosity can be produced. The rubber sheet has problems such as uneven thickness and serious deformation of the product, and a manufacturing process for rubber product production equipment is proposed.

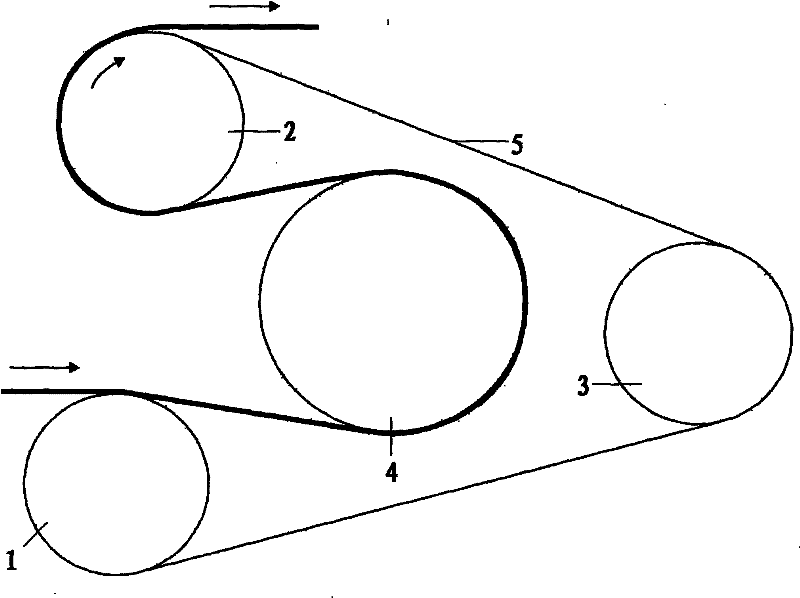

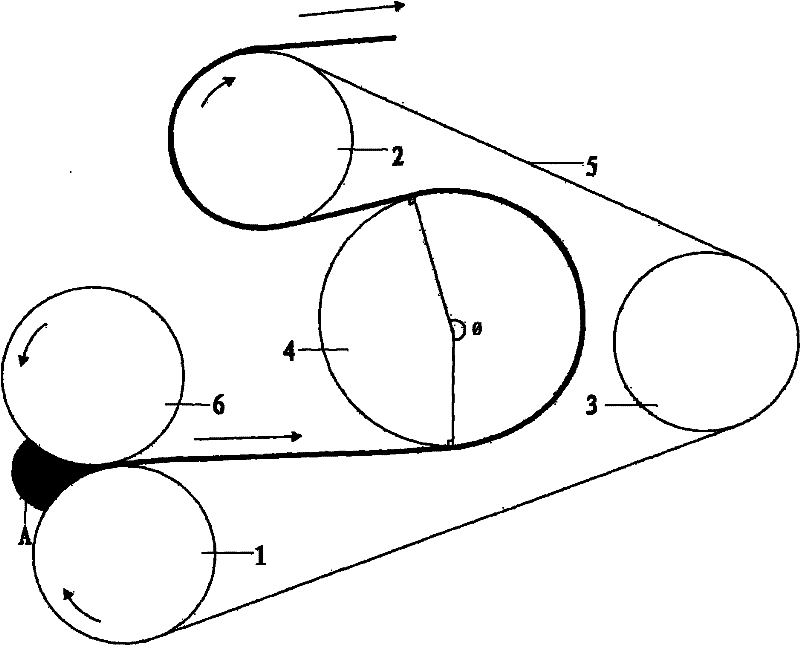

[0044] The rubber product production equipment of the present invention combines two sets of equipment of the prior art calender and flat belt drum vulcanizer into a set of equipment, which consists of a drive motor, four rollers, a heating vulcanization dru

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap