Corrugated board production line intelligent control system

An intelligent control system and corrugated cardboard technology, applied in the general control system, control/regulation system, program control, etc., can solve the problems of affecting the speed of the whole line, large loss of equipment maintenance failure, and cost reduction, so as to reduce the defective rate, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

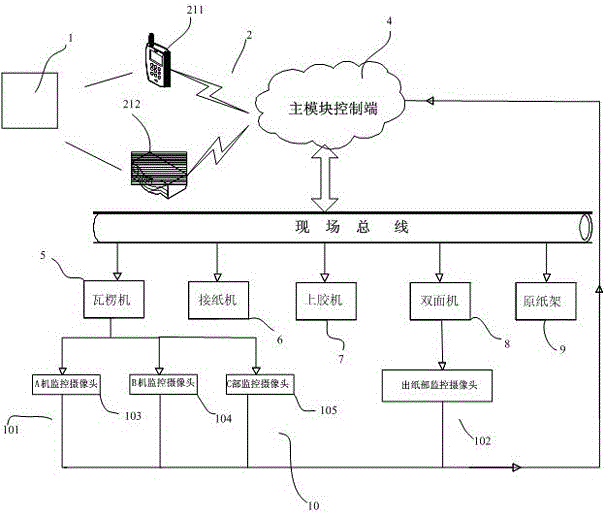

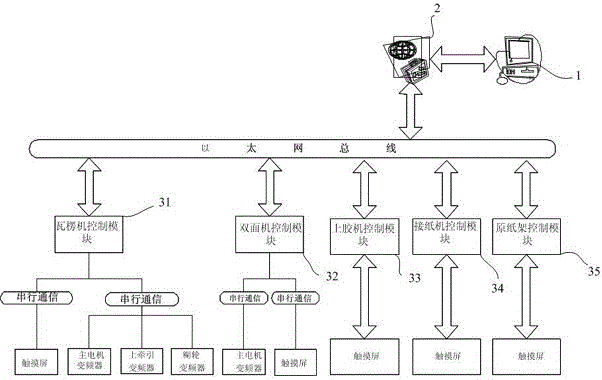

[0015] see Figure 1-Figure 2 , an embodiment of an intelligent control system for a corrugated cardboard production line of the present invention, including corrugated production equipment, a remote control terminal 1, a wireless communication module 2, a main module control terminal 4 and a sub-control module 3 for controlling each corrugated production equipment, the The remote control terminal 1 is used to display the control menu and the status of the corrugated equipment and send control signals according to the displayed control menu, and the control terminal 4 of the main module receives and transmits the control signals sent by the remote control terminal 1 through the wireless communication module 2 The main module control terminal 4 is connected to the sub-control module 3 through the Ethernet bus, and the sub-control module 3 is connected to each main control

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap