Sucralose-6-ester purification method

A technology of sucralose and preset conditions, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problem of low yield of sucralose-6-ethyl ester, difficulty in subsequent waste liquid treatment, separation of Low efficiency and other problems, to achieve the effect of reducing impurity content, strong practicability and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

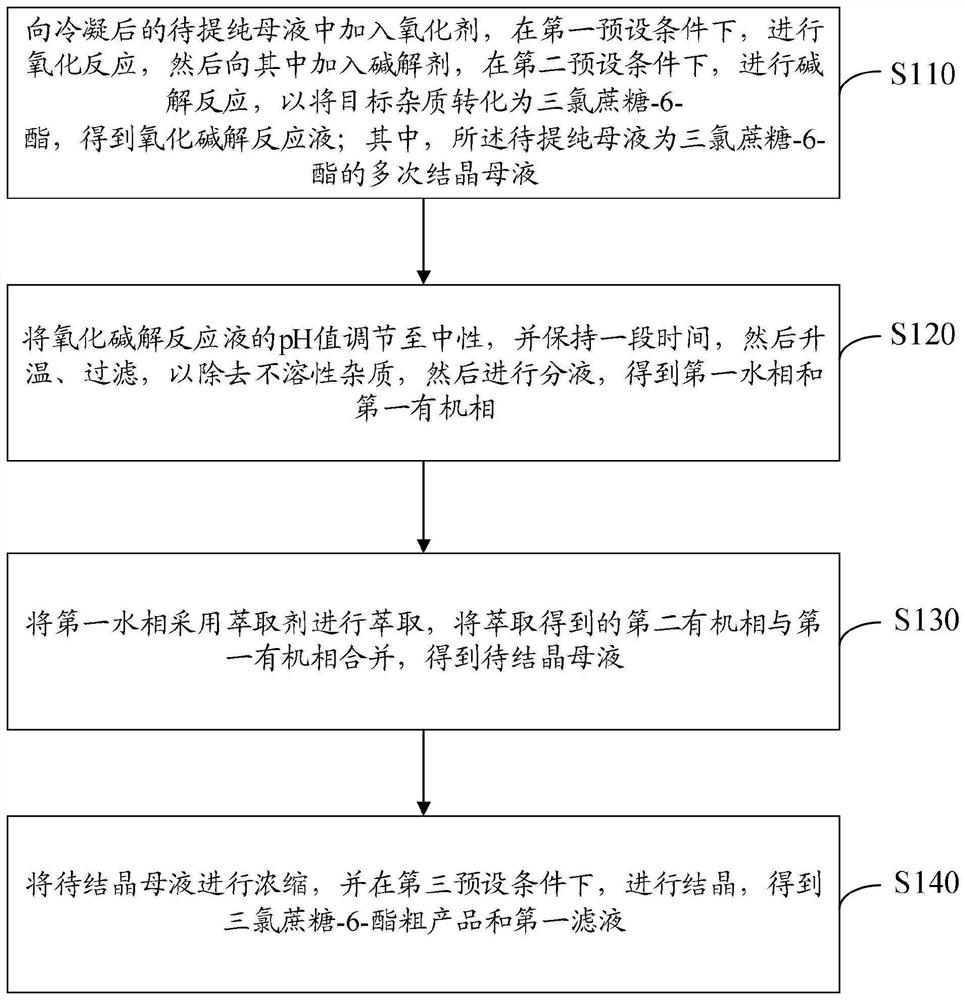

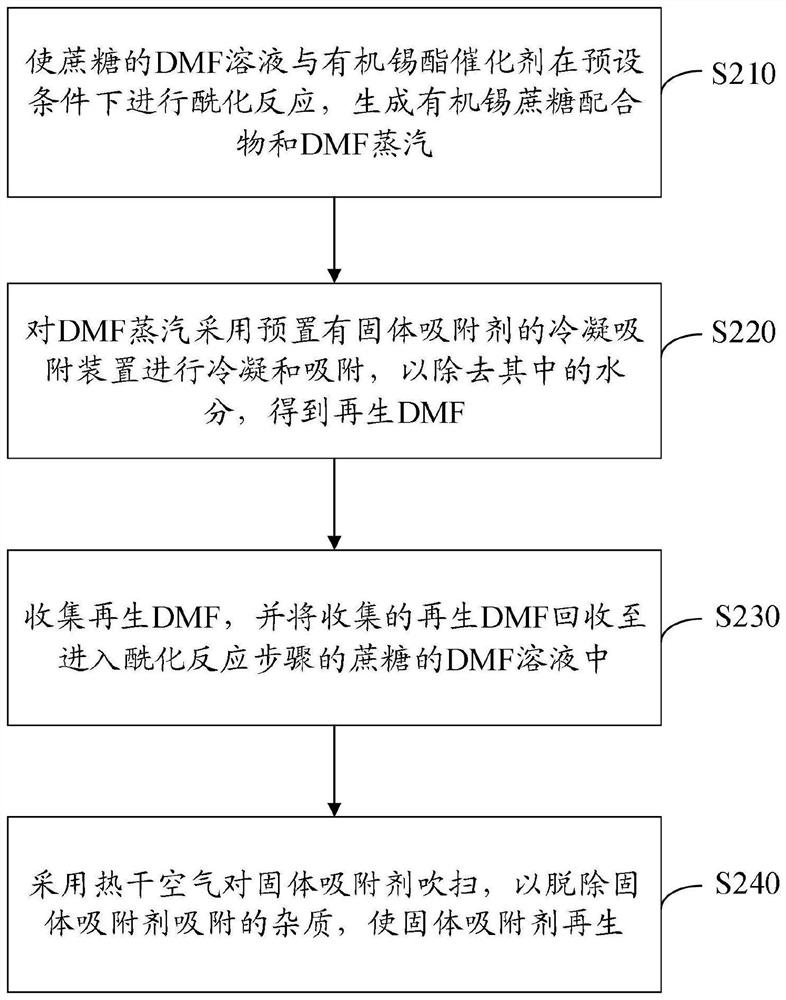

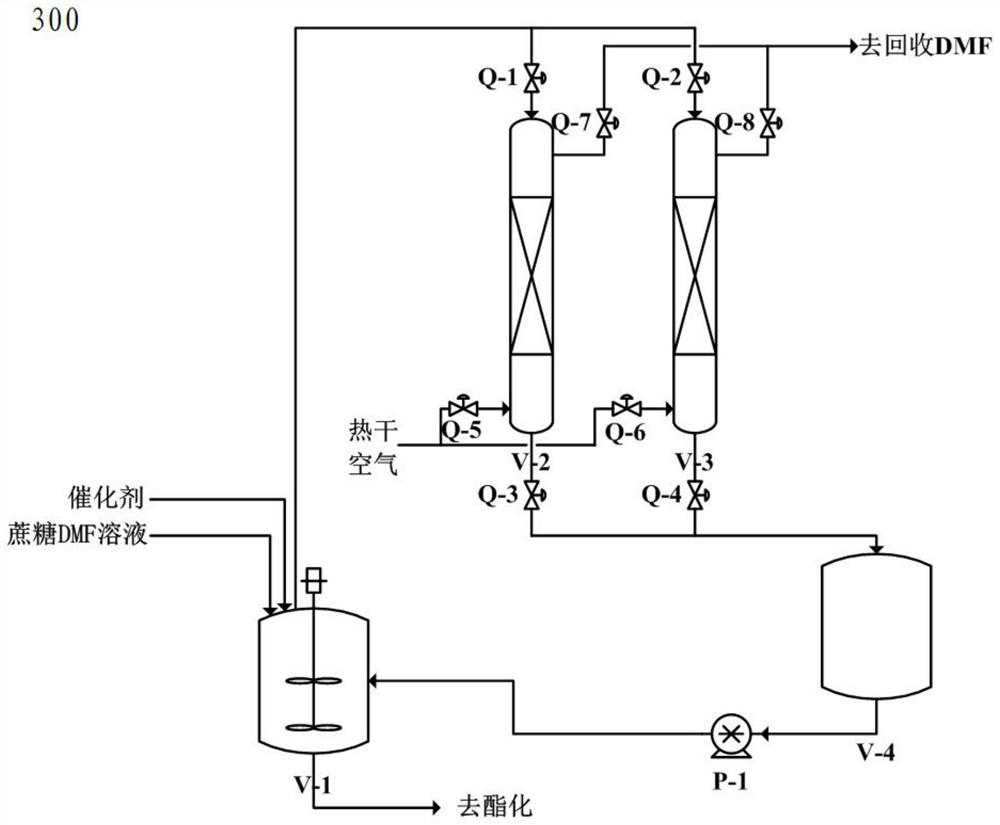

Method used

Image

Examples

Embodiment 1

[0090] a. Take 1000mL of the secondary mother liquor of sucralose-6-acetate (the initial concentration of sucralose-6-acetate is 32g / L) and add it into a 2000mL three-necked flask, and cool down to 2±2°C. Hydrogen peroxide with a mass fraction of 27.5% was added dropwise to carry out the oxidation reaction. The amount of hydrogen peroxide was 120 mL. After the hydrogen peroxide was added dropwise, it was incubated for 6 hours, and the temperature was maintained at about 5°C.

[0091] b. After the reaction of the materials in step a, add 125mL of dimethylamine with a mass fraction of 40% to carry out the alkali hydrolysis reaction. The reaction temperature is controlled at about 5°C, and the pH of the reaction is controlled at about pH=9. After the pH is stable, keep warm and maintain the alkali hydrolysis The time is controlled at about 10 hours.

[0092] c. Add hydrochloric acid with a mass fraction of 30% to the reaction solution in step b above, and adjust its pH value to ab

Embodiment 2

[0096] a. Take 1000mL of the secondary mother liquor of sucralose-6-acetate (the initial concentration of sucralose-6-acetate is 32g / L) and add it into a 2000mL three-necked flask, and cool down to 2±2°C. Hydrogen peroxide with a mass fraction of 27.5% was added dropwise to carry out the oxidation reaction. The amount of hydrogen peroxide was 120 mL. After the hydrogen peroxide was added dropwise, it was incubated for 6 hours, and the temperature was maintained at about 5°C.

[0097] b. After the reaction of the materials in step a, add 125mL of dimethylamine with a mass fraction of 40% to carry out the alkali hydrolysis reaction. The reaction temperature is controlled at about 5°C, and the pH of the reaction is controlled at about pH=9. After the pH is stable, keep warm and maintain the alkali hydrolysis The time is controlled at about 10 hours.

[0098] c. Add hydrochloric acid with a mass fraction of 30% to the reaction solution in step b above, and adjust its pH value to ab

Embodiment 3

[0103] a. Take 1000 mL of the secondary mother liquor of sucralose-6-acetate (the initial concentration of sucralose-6-acetate is 32 g / L) and add it into a 2000 mL three-necked flask, and cool down to -10°C. Hydrogen peroxide with a mass fraction of 40% was added dropwise to carry out the oxidation reaction. The amount of hydrogen peroxide was 50 mL. After the hydrogen peroxide was added dropwise, the temperature was kept at about 5°C for 12 hours.

[0104] b. After the reaction of the materials in step a, add 150mL of dimethylamine with a mass fraction of 30% to carry out the alkali hydrolysis reaction. The reaction temperature is controlled at about 5°C, and the pH of the reaction is controlled at about pH=9. After the pH is stable, keep warm and maintain the alkali hydrolysis The time is controlled at about 12 hours.

[0105] c. Add hydrochloric acid with a mass fraction of 15% to the reaction solution in the above step b, and adjust its pH value to about pH=7.0. The amount

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap