Waste water deep treatment method for thickened oil extracted in oil field

A technology for advanced treatment of heavy oily sewage, applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as incomplete treatment of sewage components, residual high COD concentrated water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

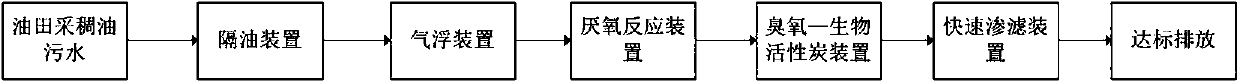

[0028] Such as figure 1 As shown, a method for advanced treatment of oilfield heavy oil wastewater, comprising the following steps:

[0029] S1. Oil separation, put the heavy oil sewage from the oil field into the grease trap, and after standing for a certain period of time, the heavy oil and impurities settled in the grease trap will accumulate in the sludge bucket at the bottom of the pool and pass through the sludge discharge pipe Into the sludge pipe, the rest is the overflow from the upper layer; in this embodiment, as a preference, the settling time of the heavy oil sewage from the oil field in the grease trap is 5-10 minutes.

[0030] Its working principle is to use the different specific gravity of suspended solids and water in wastewater to achieve the purpose of separation. The grease trap is directly installed on the channel containing sewage and oily water, and the sewage outlet is aligned with the inlet of the oil-water separator with a grid, and can be connected to

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap