Environment-friendly water-based imitation stone coating and its raw materials, preparation method and application

A water-based, water-based color paste technology, applied in the direction of coating, can solve the problems of less change, high cost, single color and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

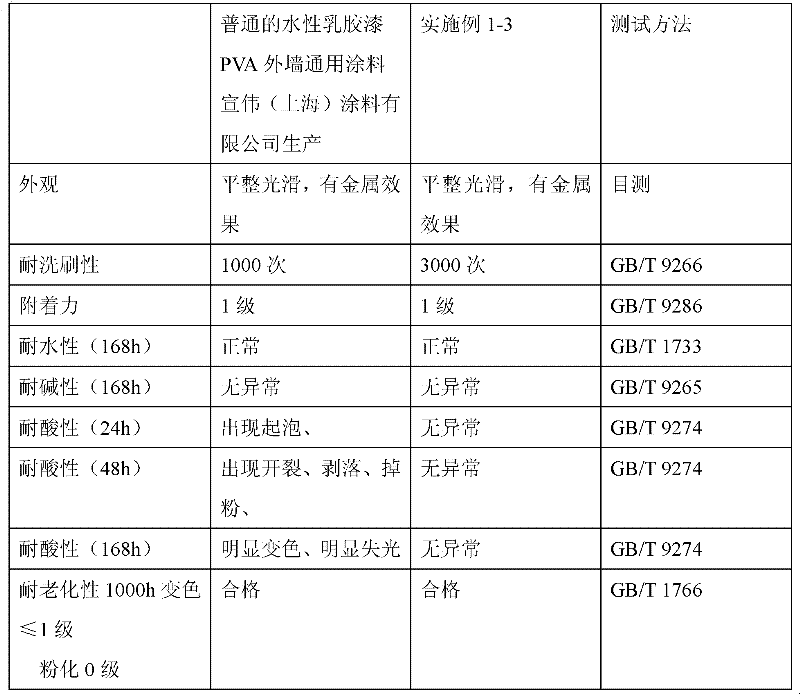

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of component A in the following examples is as follows: add the water-based elastic acrylic emulsion into deionized water according to the formula of component A, add defoamer, preservative, thickener, film-forming Auxiliary, antifreeze and softener, stir for 10 minutes after adding.

[0050] The preparation method of component B in the following examples is as follows: according to the formula of component B, add 50wt% of wetting and dispersing agent, neutralizing agent, defoamer, 50wt% of antiseptic, pigment and filler to deionized water 50wt%, after uniform dispersion, use a sand mill to grind to ≤401μm, add the remaining defoamer, remaining preservative, water-based elastic acrylic emulsion, film-forming aid, antifreeze, thickener and remaining defoaming agent under stirring at 500rpm ionized water.

[0051] The preparation methods of component C in the following examples are as follows: add water-based elastic acrylic emulsion to deionized wate

Embodiment 1

[0053] The formula of component A is:

[0054] Water-based elastic acrylic emulsion National Starch 4700

85.0%

Defoamer SN-154

0.1%

Preservative P113

1.0%

Thickener R278

5.0%

Coalescent Texanol

3.2%

Antifreeze Propylene Glycol

1.0%

Softener Magnesium Silicate

2.4%

Deionized water

2.3%

[0055] The formula for component B is:

[0056] Water-based elastic acrylic emulsion National Starch 4700

56.0%

Pigment and filler rutile titanium dioxide R828

31.0%

Wetting and dispersing agent Dow CF-10

2.2%

Neutralizer AMP-95

0.4%

Defoamer SN-154

0.4%

Preservative P113

0.2%

Thickener R278

2.0%

Coalescent Texanol

1.8%

Antifreeze Propylene Glycol

2.0%

Deionized water

4%

[0057] The formula of component C is:

[0058] Water-based elastic

Embodiment 2

[0069] The formula of component A is:

[0070] Water-based elastic acrylic emulsion Polycar BLJ-963M

88.0%

Defoamer SN-154

0.3%

Preservative P113

1.5%

Thickener R278

1.8%

Coalescent Texanol

3.0%

Antifreeze Propylene Glycol

1.4%

Softener Magnesium Silicate

3.0%

Deionized water

1.0%

[0071] The formula for component B is:

[0072] Water-based elastic acrylic emulsion Polycar BLJ-963M

66.2%

Pigment titanium cyanine blue

18.2%

Wetting and dispersing agent Dow X-405

1.8%

Neutralizer AMP-95

0.3%

Defoamer SN-154

0.3%

Preservative P113

0.4%

Thickener R278

1.0%

Coalescent Texanol

3.5%

Antifreeze Propylene Glycol

2.2%

Deionized water

6.1%

[0073] The formula of component C is:

[0074] Water-based elastic acrylic emulsion Poly

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap