Batch feeding and discharging system and method for continuous production type vacuum atmosphere furnace

A technology of feeding and unloading and batching, applied in the direction of furnace, furnace components, charge control, etc., can solve the problems of reducing production efficiency, wasting protective gas, material and structure restrictions, etc., to reduce production costs, save protective gas, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

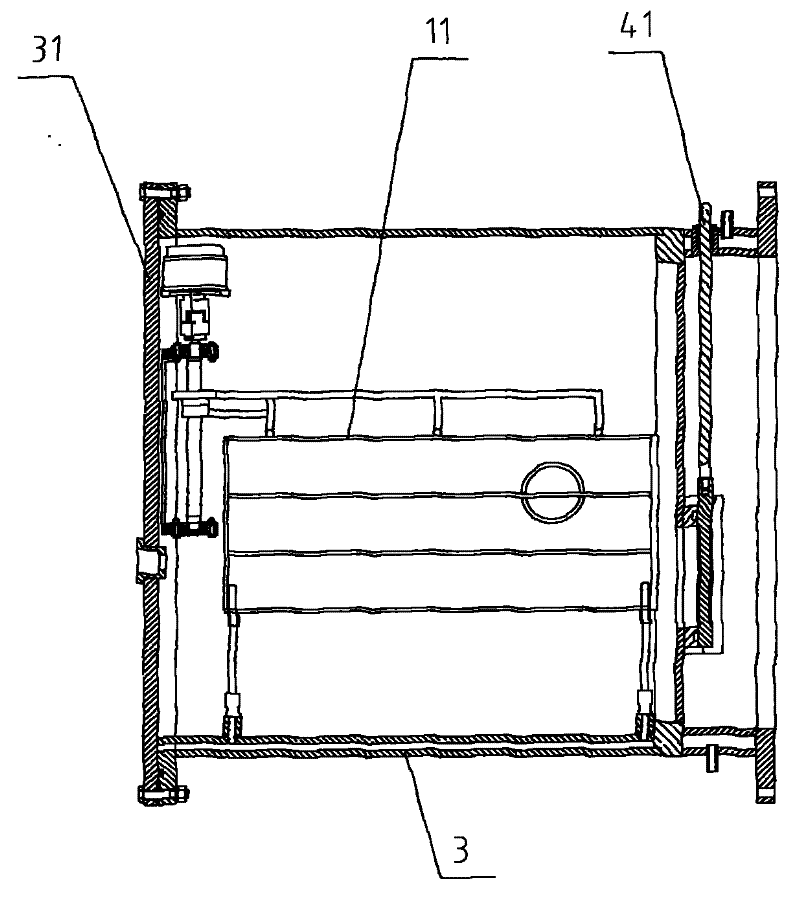

[0031] The invention discloses a batch feeding and discharging system, which consists of a feeding device and a discharging device.

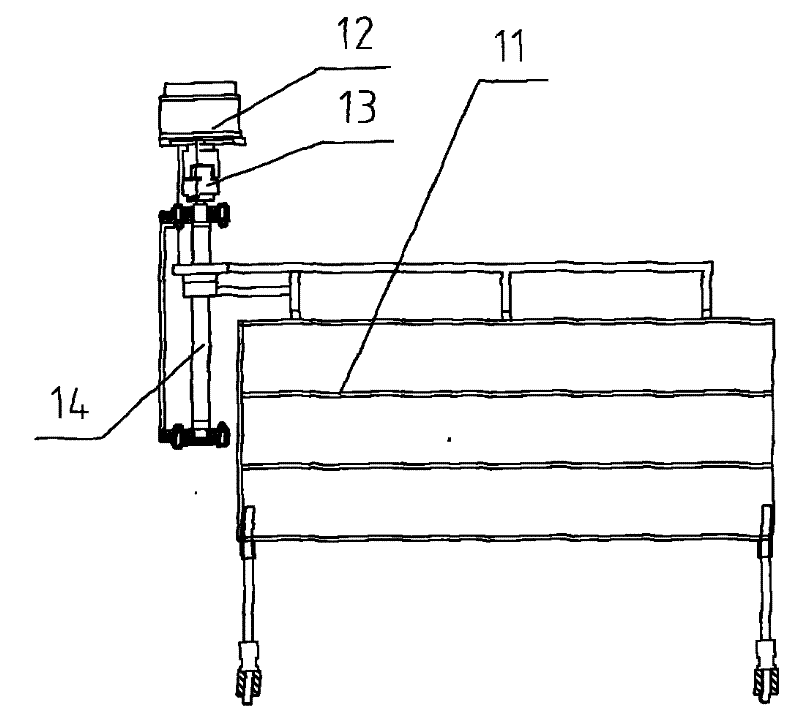

[0032] See figure 1 , wherein the feeding device includes a loading box support I 11, the number of layers of the loading box support I 11 is two or more, and also includes a motor I 12, which can drive the screw mechanism I to drive The loading box support I 11 of the feeding device moves up and down, and the described screw mechanism 1 includes a shaft coupling 13 and a leading screw pair 14 connected with the motor I 12, and the leading screw pair 14 can move up and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap