Surrounding centrifugal sucrose-6-ester continuous production equipment and production method

A kind of production equipment and centrifugal technology, which is applied in the surrounding centrifugal sucrose-6-ester continuous production equipment and production field, can solve the problems of low production efficiency, shorten the production process of sucrose-6-ester, etc., and achieve the improvement of production efficiency and increase Tinning reaction efficiency, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings, but the present invention can also be implemented in various forms, so the present invention is not limited to the embodiments described hereinafter. In addition, in order to describe the present invention more clearly, there is no Connected parts will be omitted from the drawings;

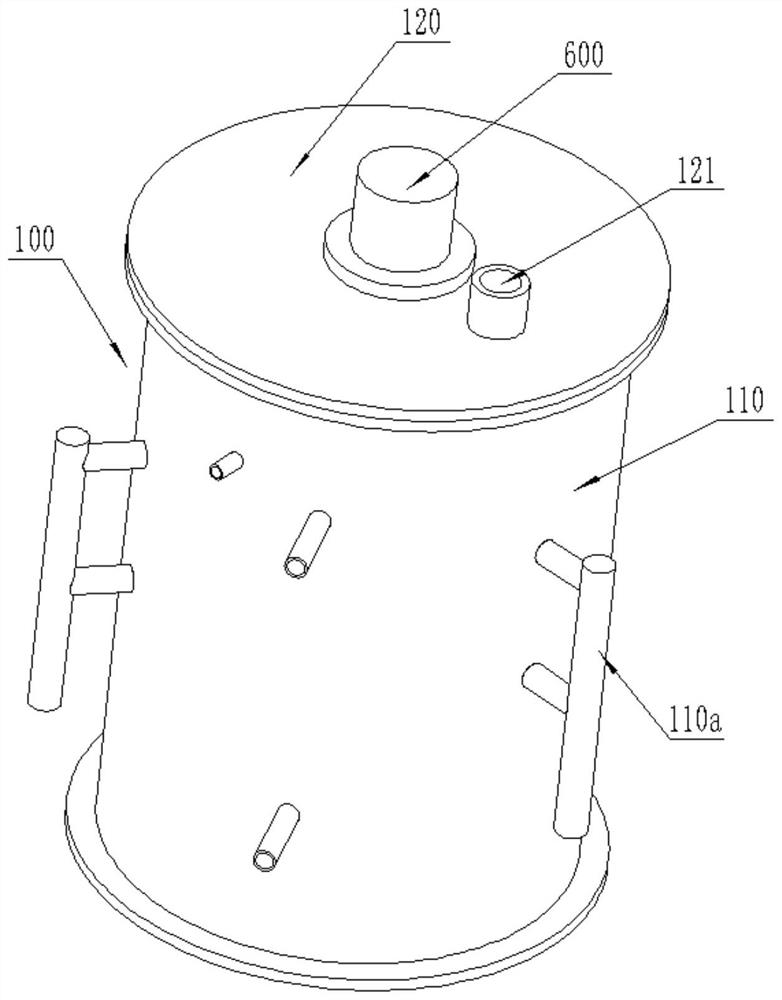

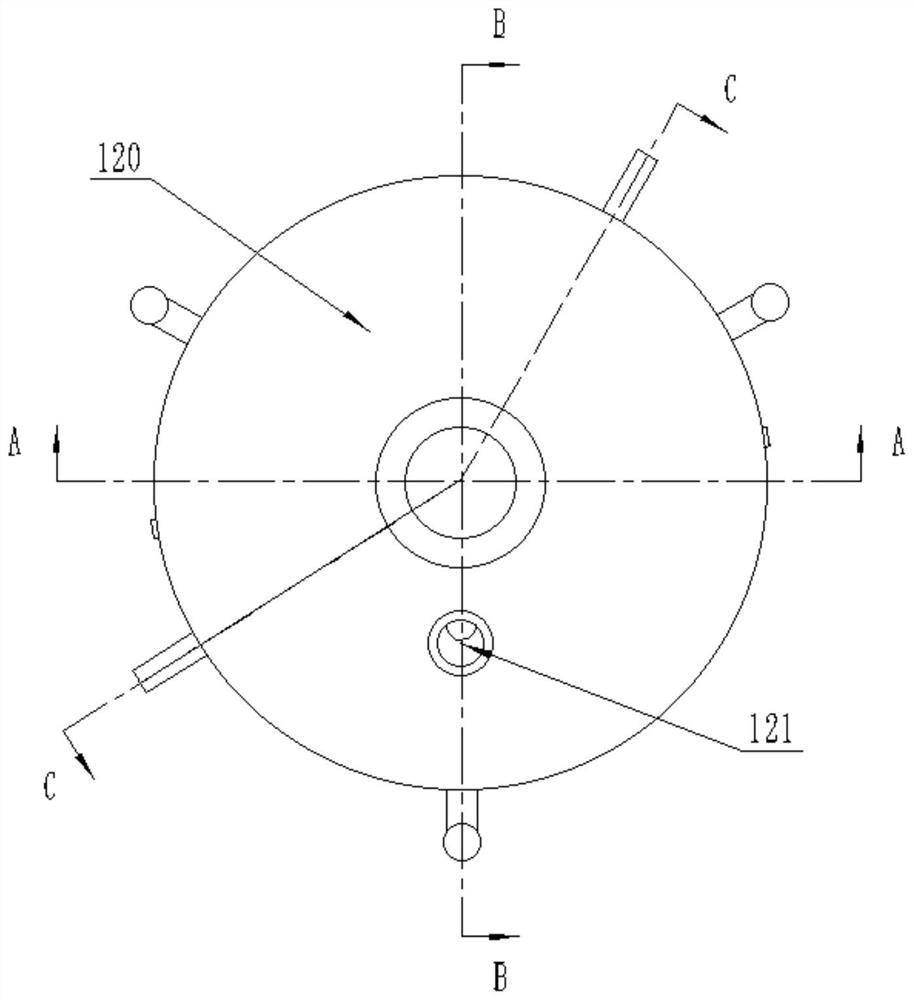

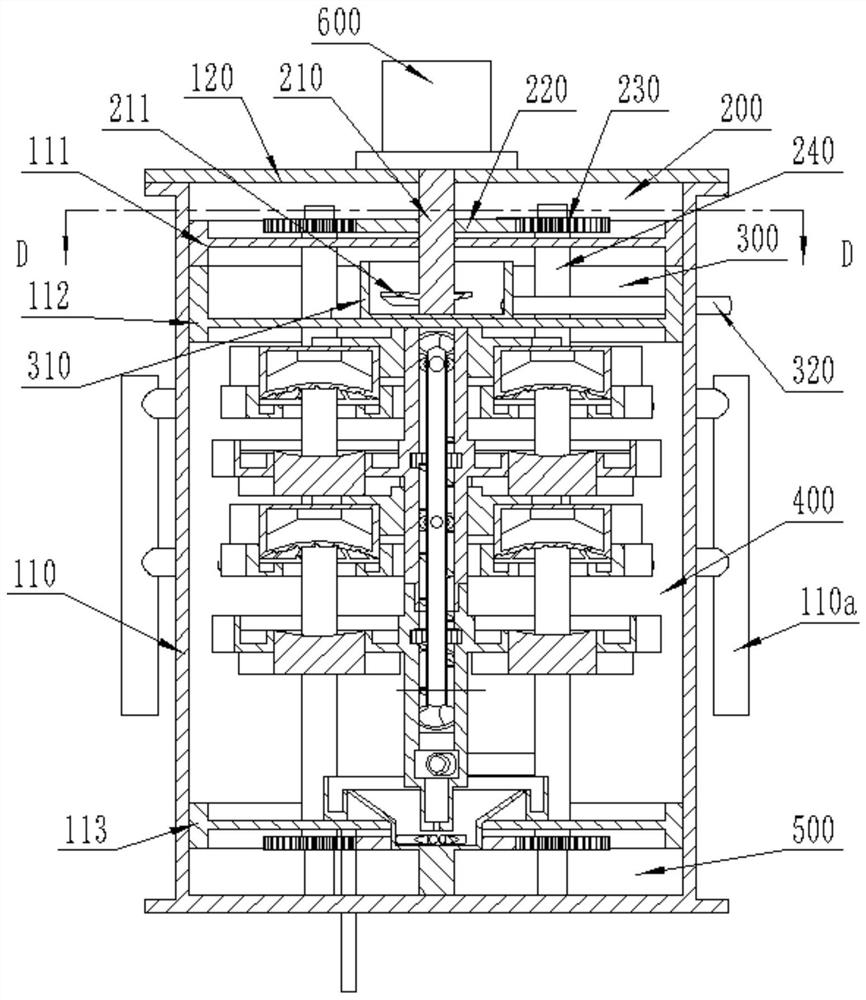

[0049] such as 1 to image 3 As shown, a continuous centrifugal sucrose-6-ester production equipment includes: a tank body 100, a main transmission chamber 200, a stirring chamber 300, a distillation chamber 400, an auxiliary transmission chamber 500, and a driving motor 600;

[0050] The tank body 100 is composed of two parts connected to each other, the main tank 110 and the tank cover 120. During installation or disassembly, the tank cover 120 can be disassembled for easy installation and maintenance. The tank cover 120 is equipped with a driving motor 600, and the tank co

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap