Automatic corrugated pipe sensor of instrument

A bellows and sensor technology, applied in the field of sensors, can solve problems such as micro pressure cannot be measured, large leakage, easy freezing and blocking, etc., and achieve the effect of stable physical properties, small tension and strong stretching force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

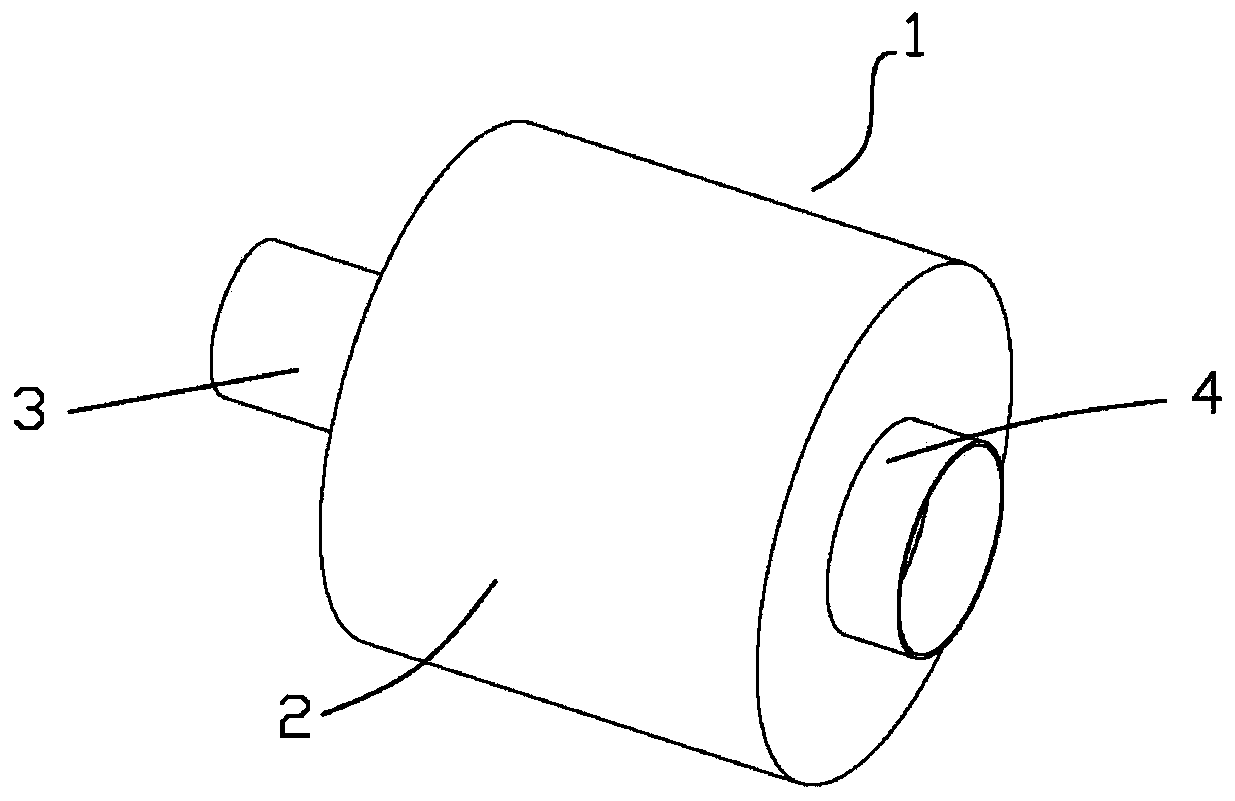

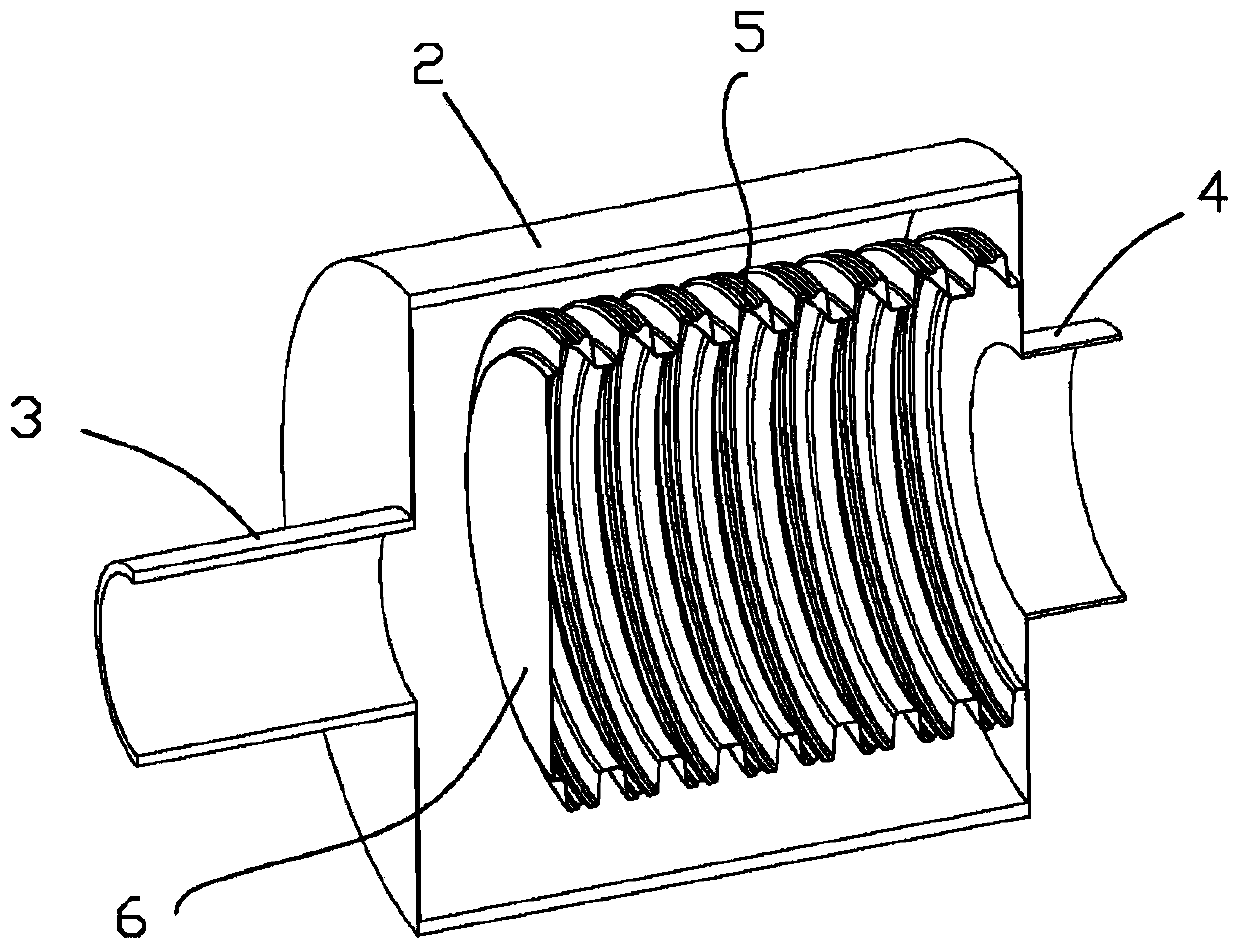

[0021] Such as figure 1 with figure 2 As shown, the instrument automation bellows sensor 1 includes a hollow cylindrical housing 2, the head of the housing 2 is provided with an inlet joint 3, and the tail of the housing 2 is provided with an outlet joint 4, the housing 2 is provided with a bellows 5, the head of the bellows 5 is provided with a sealing plate 6, the tail of the bellows 5 communicates with the outlet connection 4, and the bellows 5 is filled with silicone oil.

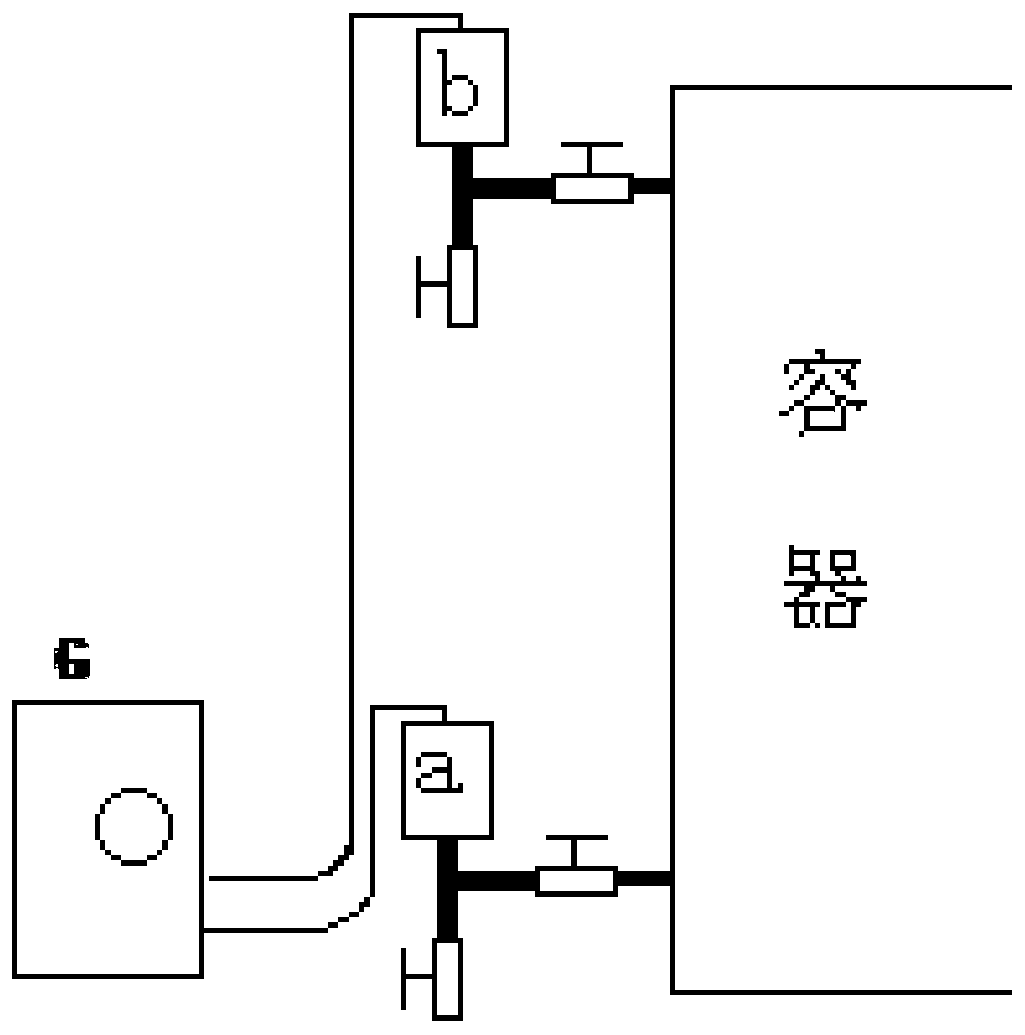

[0022] When in use, the inlet connection 3 is connected to the measured container or the measured pipeline, and the outlet connection 4 is connected to the transmitter or p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap