Continuous decontamination process for organic chlorination reaction byproduct hydrochloric acid

A technology for by-product hydrochloric acid and chlorination reaction, applied in inorganic chemistry, chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, etc., can solve the problems of increasing the "three wastes" emissions, failing to meet the synthetic acid standard, and having no use value of hydrochloric acid. , to achieve the effect of ensuring the effect of hydrochloric acid removal, reducing the discharge of three wastes, and improving the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

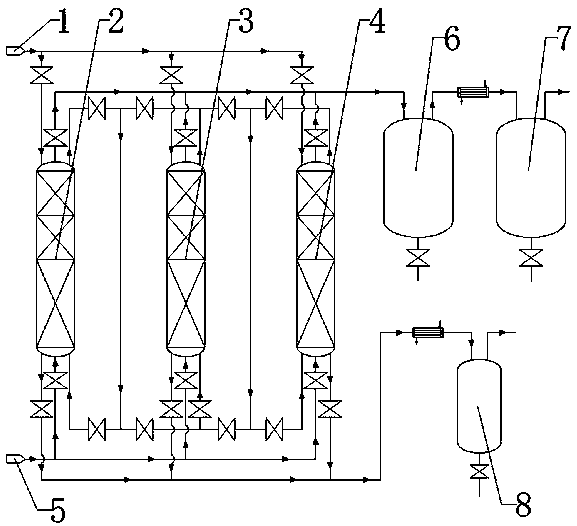

[0016] Embodiment 1-toluene chlorination produces trichlorobenzyl process by-product hydrochloric acid treatment process

[0017] Chlorination reaction equation:

[0018] as attached figure 1 Shown, a kind of organic chlorination reaction by-product hydrochloric acid continuous impurity removal process, described organic chlorination reaction by-product hydrochloric acid 5 impurity removal process comprises the following steps: a, the by-product hydrochloric acid 5 solution that organic chlorination reaction generates Feed in from the feed inlet at the bottom of the primary adsorption resin tower at a flow rate of 15BV / h, and discharge from the top outlet of the primary adsorption resin tower; The flow rate of / h is passed into from the feed port at the bottom of the secondary adsorption resin tower, and the finished product hydrochloric acid is temporarily stored in the hydrochloric acid buffer tank 6 from the discharge port at the top of the secondary adsorption resin to

Embodiment 2

[0026] Embodiment 2-Process of producing p-fluorotrichlorobenzyl by-product hydrochloric acid by chlorination of p-fluorotoluene

[0027] Chlorination reaction equation:

[0028] as attached figure 1 Shown, a kind of organic chlorination reaction by-product hydrochloric acid continuous impurity removal process, described organic chlorination reaction by-product hydrochloric acid 5 impurity removal process comprises the following steps: a, the by-product hydrochloric acid 5 solution that organic chlorination reaction generates Feed in from the feed inlet at the bottom of the primary adsorption resin tower at a flow rate of 10BV / h, and discharge from the top outlet of the primary adsorption resin tower; The flow rate of / h is passed into from the feed port at the bottom of the secondary adsorption resin tower, and the finished product hydrochloric acid is temporarily stored in the hydrochloric acid buffer tank 6 from the discharge port at the top of the secondary adsorption

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap