Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Flame cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame cutting is oxygen cutting in which the appropriate part of the material to be cut is raised to ignition temperature by an oxy-fuel gas flame (definition from BS 499:Part 1:1991 Section 7 No.72 002). Also known as oxy-fuel cutting, the process is used for separating and shaping steel components.

Method for preventing casting blank from having flame cutting cracks

ActiveCN110814309APrevent flame cutting cracksFlame cutting crack avoidanceFlame cuttingFusion zone

Owner:攀钢集团西昌钢钒有限公司

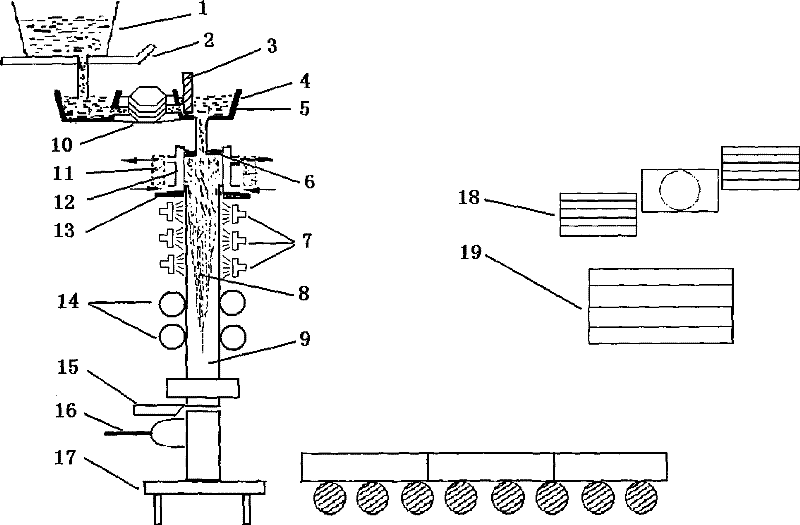

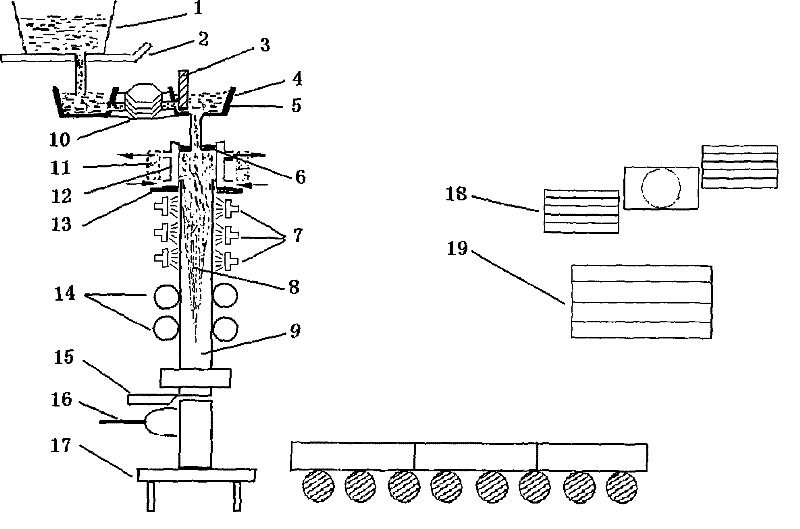

Continuous casting method for producing round blank with diameter larger than Phi800m on straight continuous casting machine

ActiveCN101428335BSolve technical problems that are easy to solidifyPouring evenlyMelt-holding vesselsLiquid coreSlag

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Movable fully-closed dust hood special for flame cutting table

ActiveCN113510104AImprove convenienceDirt cleaningCleaning using toolsElectric machineClassical mechanics

The invention discloses a movable fully-closed dust hood special for a flame cutting table. The movable fully-closed dust hood comprises a hood body (1), a walking beam (2), a walking mechanism (3), walking tracks (4) and track beam columns (9), the hood body (1) is integrally of a movable structure driven by the walking mechanism (3), the hood body (1) adopts a plate rib structure, the walking mechanism (3) is positioned at the bottom of the hood body (1), the two symmetrically-arranged walking tracks (4) are supported by the track beam columns (9) and fixed to the ground, the walking mechanism (3) can be driven by a motor (5) to move in the length direction of the walking tracks (4), a suction port (7) is formed in the top of the hood body (1), a pipeline (8) communicating with the interior of the hood body (1) is installed on the suction port (7), and a butterfly valve (6) is installed on the pipeline (8). The movable fully-closed dust hood is movably located above a cutting machine during normal operation, when the cutting machine is overhauled, the movable hood is moved to the side to make an overhauling space, so that the overall convenience is greatly improved.

Owner:HEBEI GAOKE ENVIRONMENTAL PROTECTION GRP CO LTD

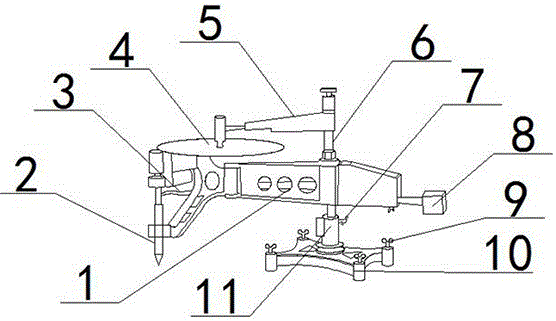

Novel semi-automatic flame cutting machine

InactiveCN106180962AReasonable designImprove cutting effectGas flame welding apparatusSemi automaticPulp and paper industry

Owner:张振堂

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap