Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Logic Control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Logic Control is a control surface originally designed by Emagic in cooperation with Mackie.

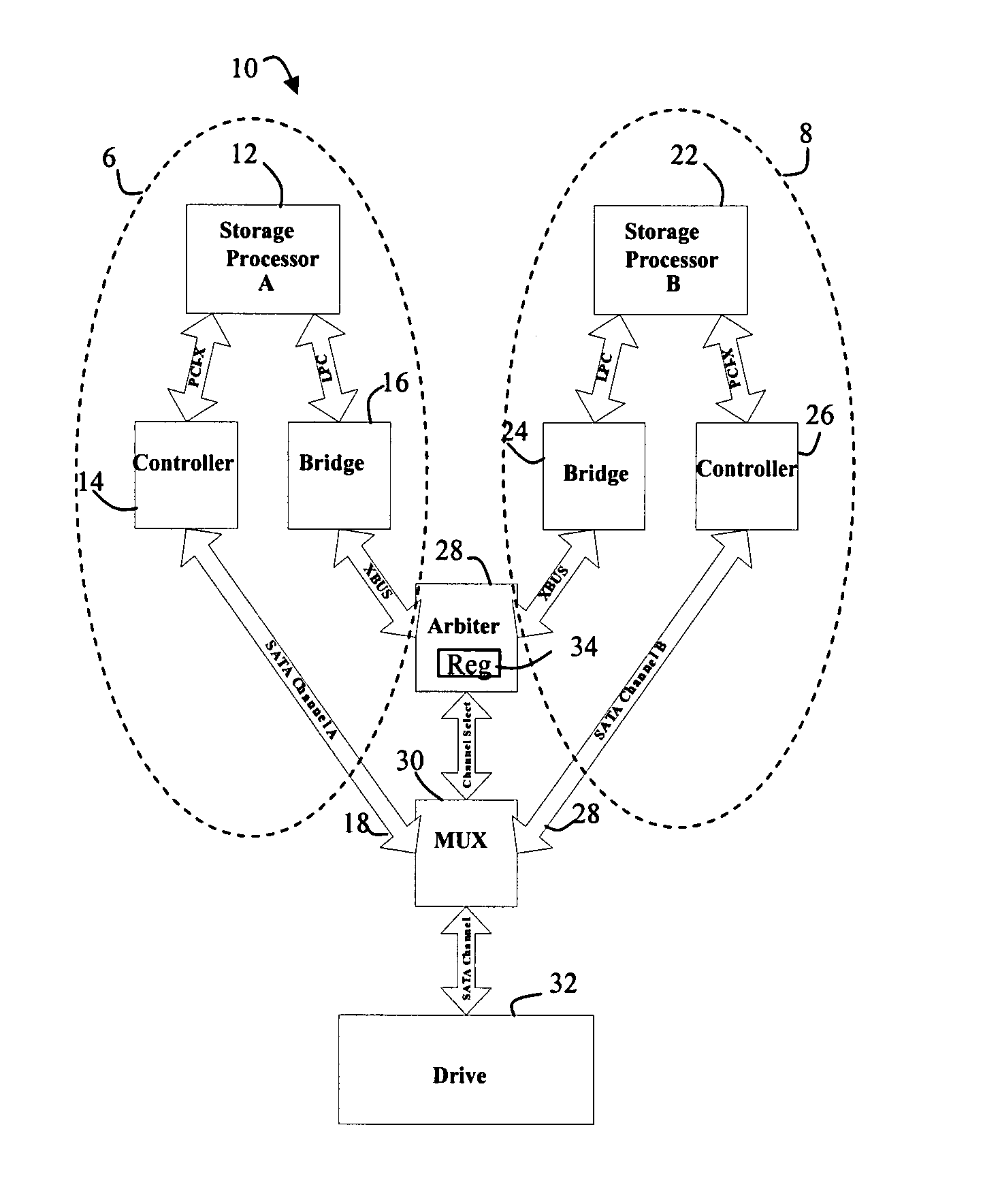

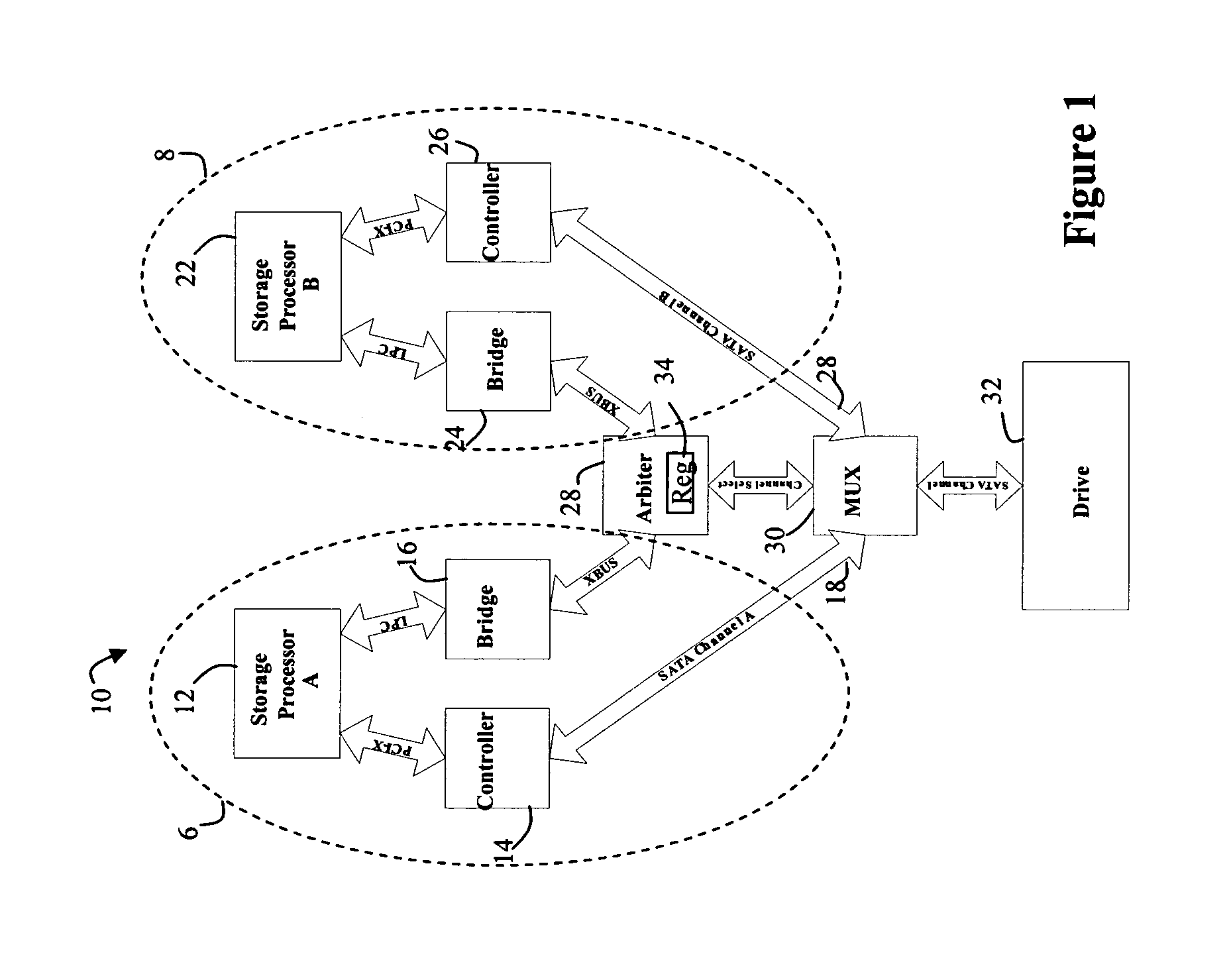

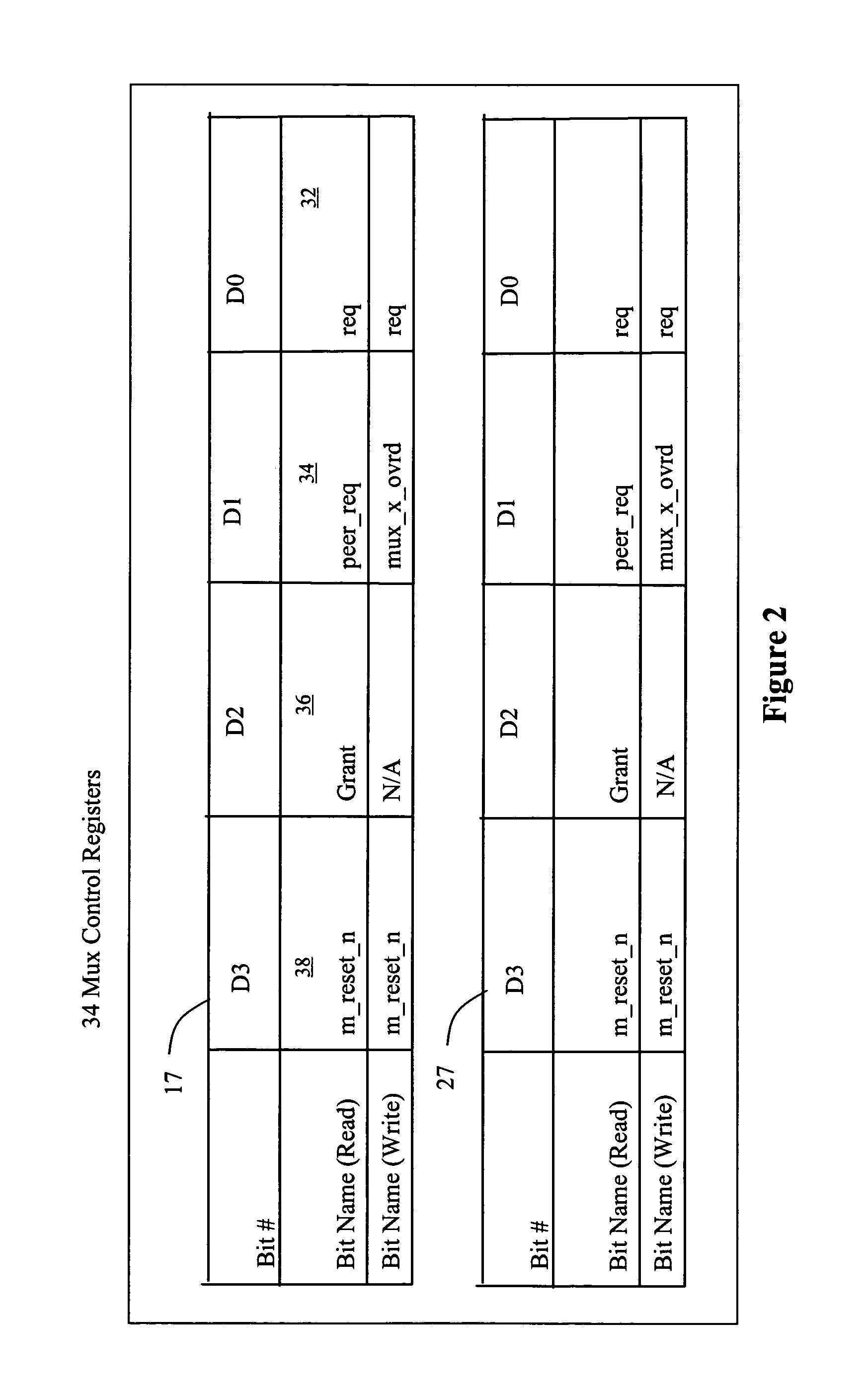

Method and apparatus for resource arbitration

Owner:EMC IP HLDG CO LLC

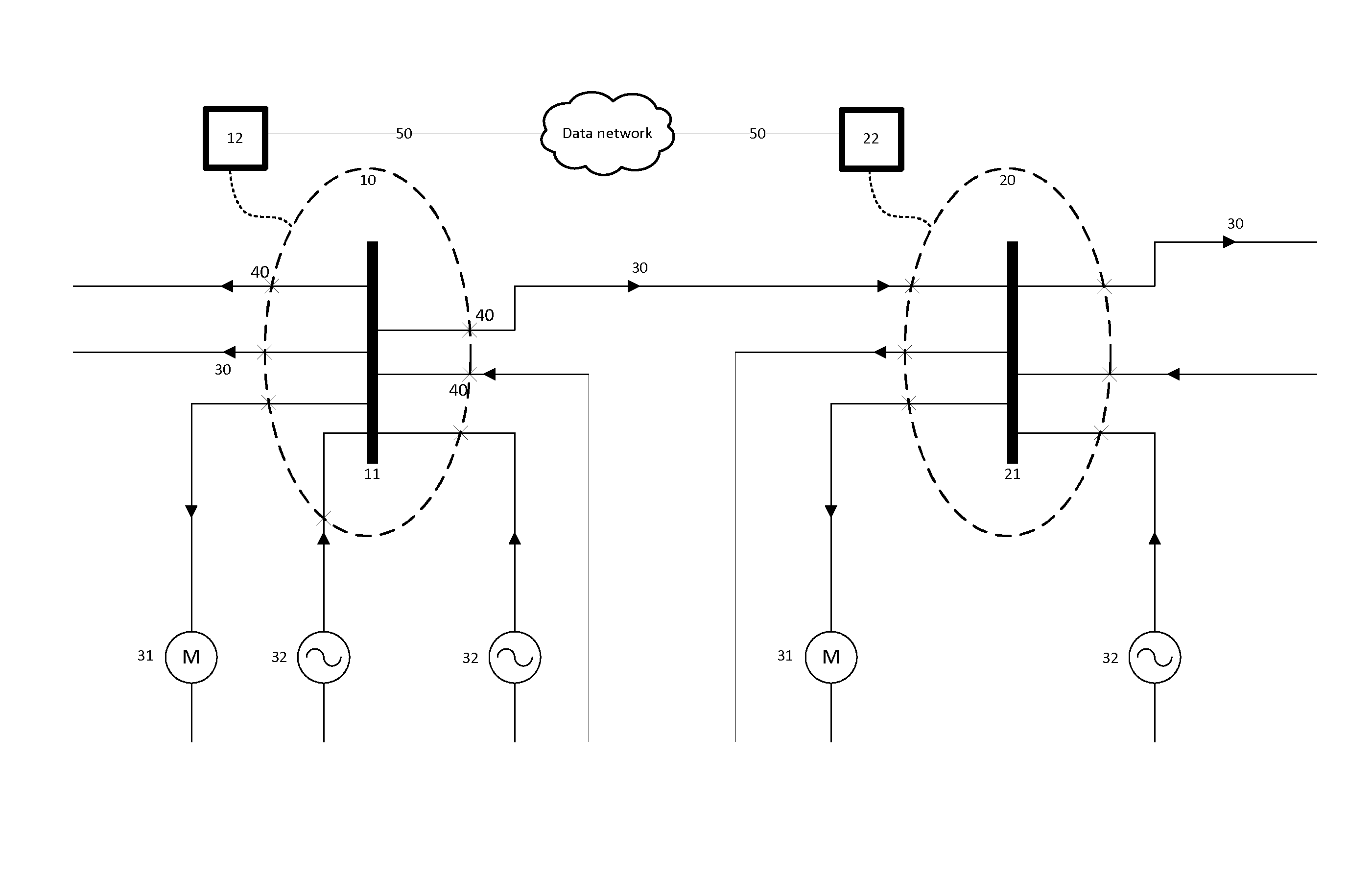

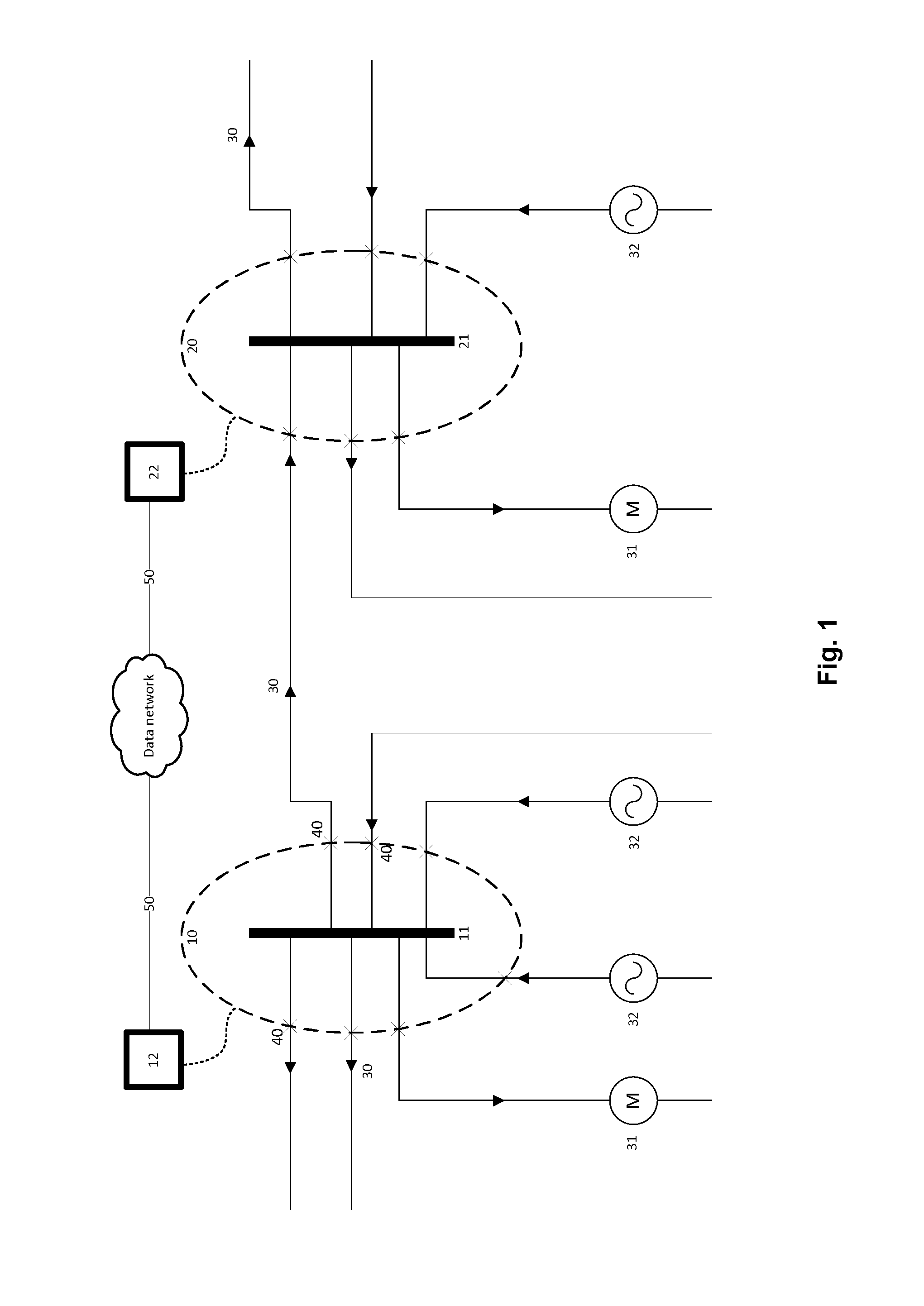

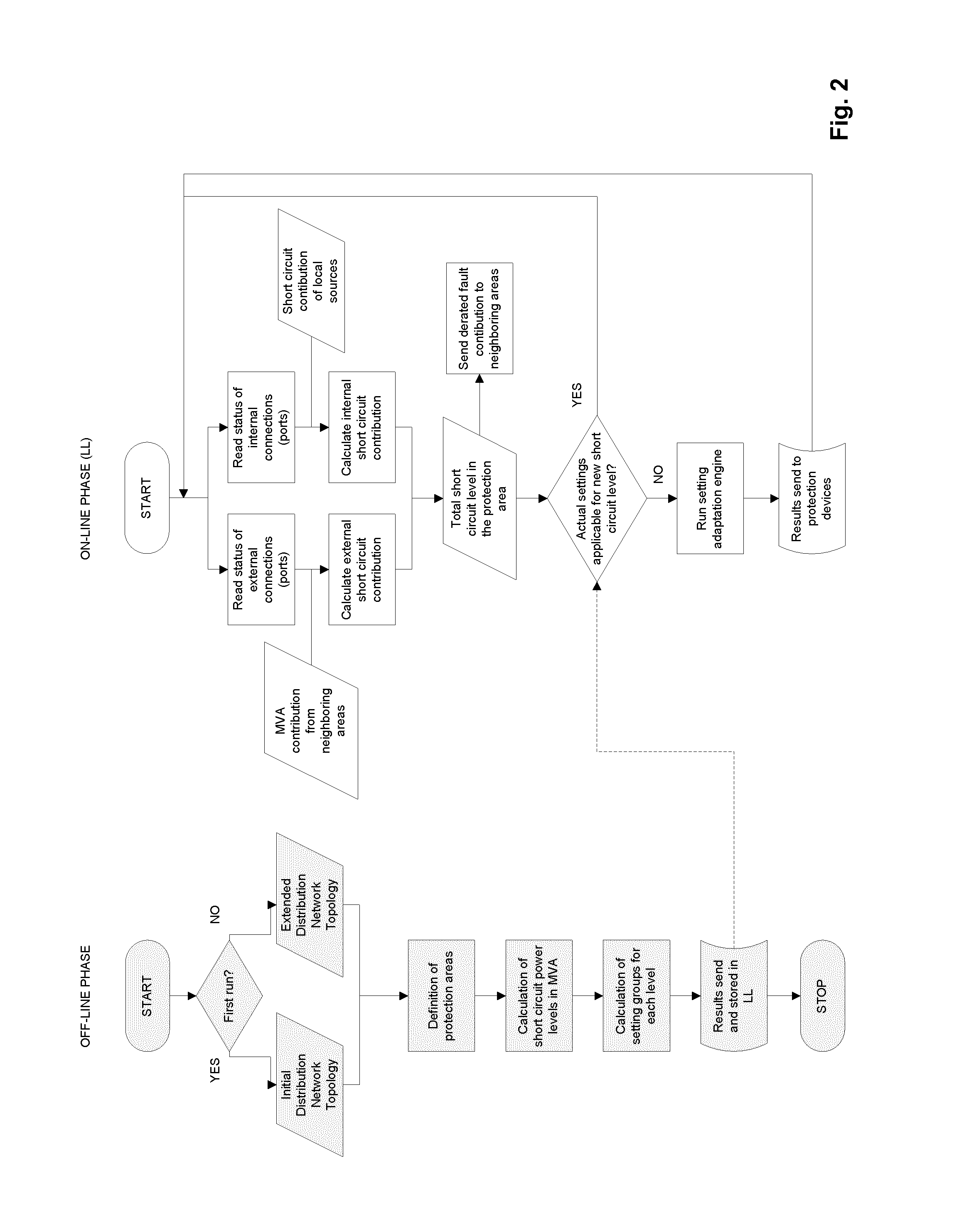

Adaptive Protection For Distribution Grid Based On Area Concept

ActiveUS20160190790A1Save spaceImprove reliabilityParameter calibration/settingArrangements responsive to excess currentBusbarEngineering

Owner:ABB (SCHWEIZ) AG

Method for processing consistency of sum-difference channel signal transmission delays through automatic calibration

InactiveCN102163980AMonitor shows calibration resultsTo achieve the purpose of delay difference calibrationBaseband system detailsDigital signal processingPeak value

The invention provides a method for processing the consistency of sum-difference channel through automatic calibration in a double-channel monopulse mechanism, and when the method is applied to the process of extracting angular error signals by using a sum-difference cross-correlation algorithm, the peak values of sum and difference signals subjected to cross-correlation can be improved effectively, thereby obtaining the maximum angular error detection sensitivity. The method is implemented by the technical scheme which comprises the following steps: in a digital signal processing module in a field-programmable gate array (FPGA) chip, inputting sum signals by a memory (first in first out FIFO1) controlled by a high-speed system clock, and inputting difference signals by a memory (FIFO2) controlled by another high-speed system clock; in a digital signal processor (DSP) chip, designing a logic control program for the whole phase calibration process, wherein the logic control program is used for receiving a phase calibration command issued by application software and controlling the read-write retardation change of the FIFO1 and the FIFO2; and through combining the DSP program with a position (pitching) phase shifter, automatically organizing a process to complete the calibration on sum-difference channel delays, thereby calibrating the sum-difference channel delays to be consistent.

Owner:10TH RES INST OF CETC

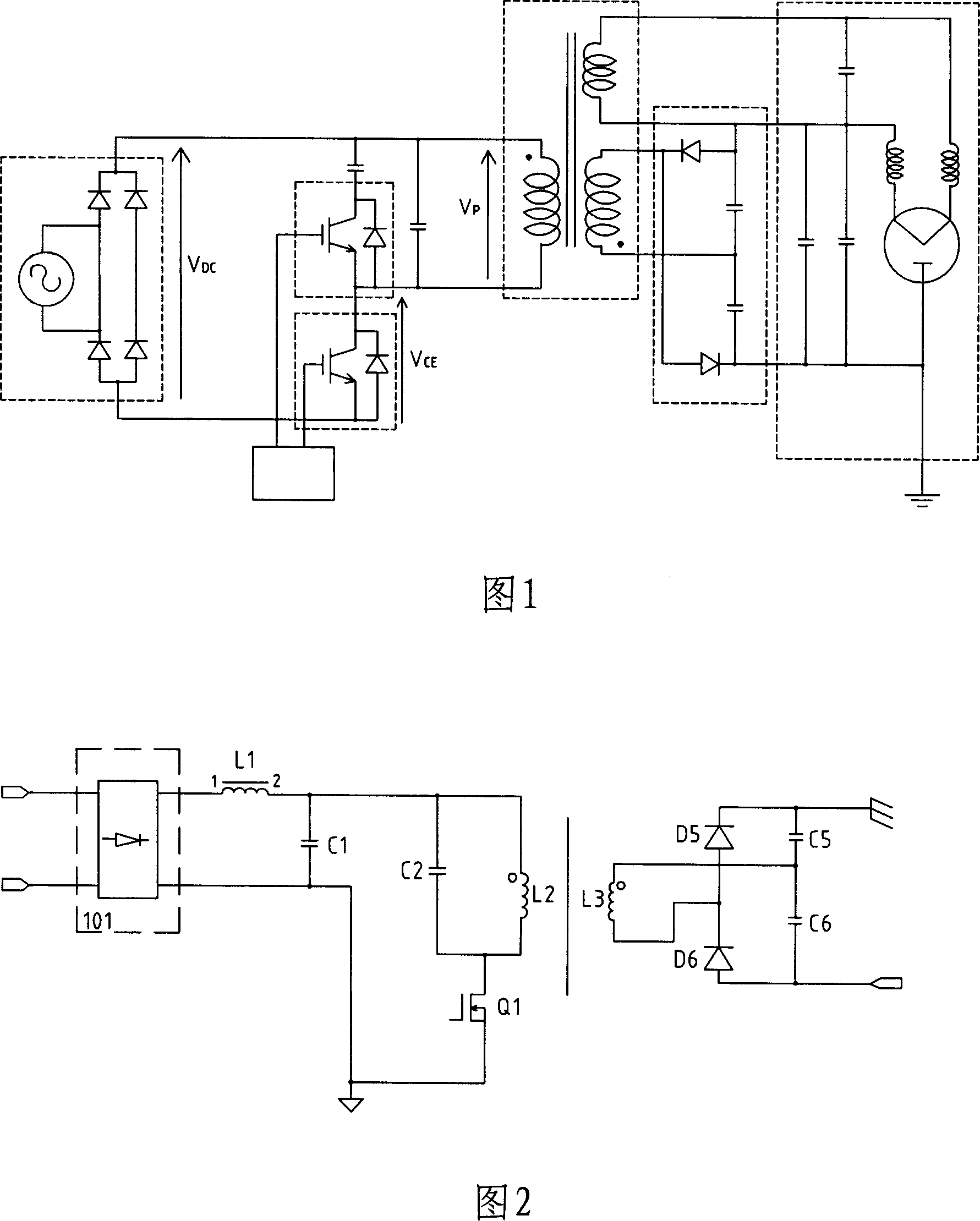

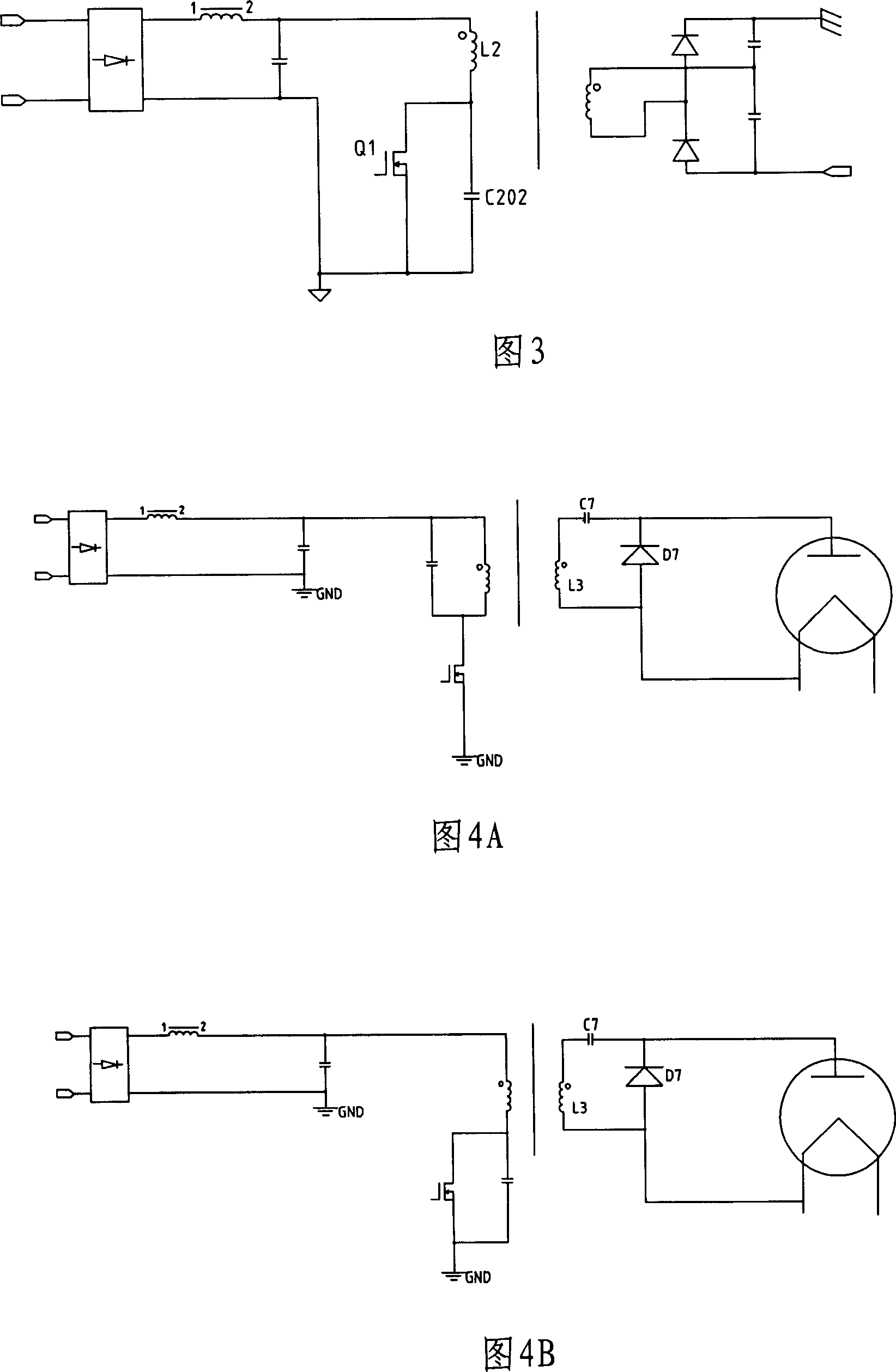

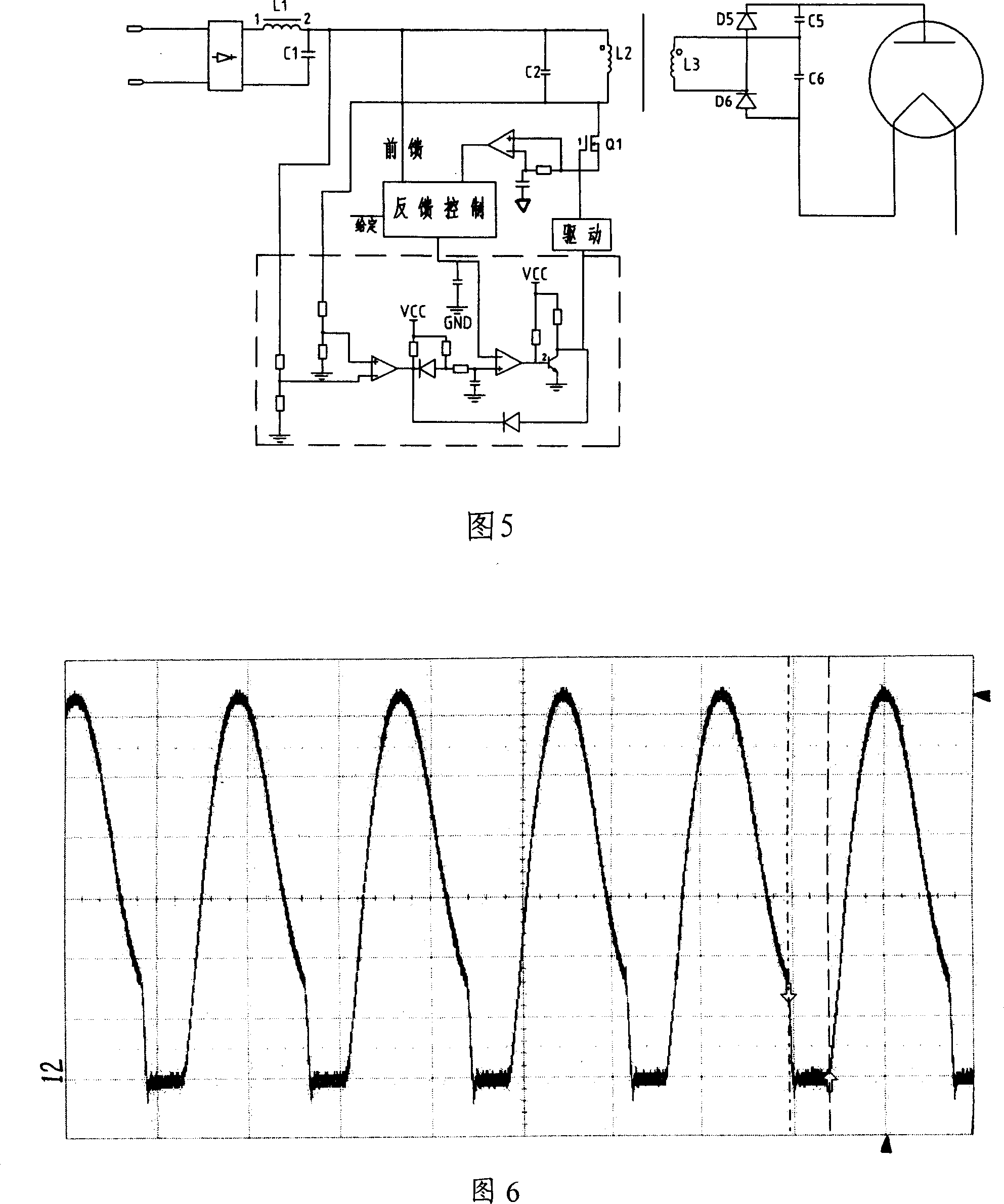

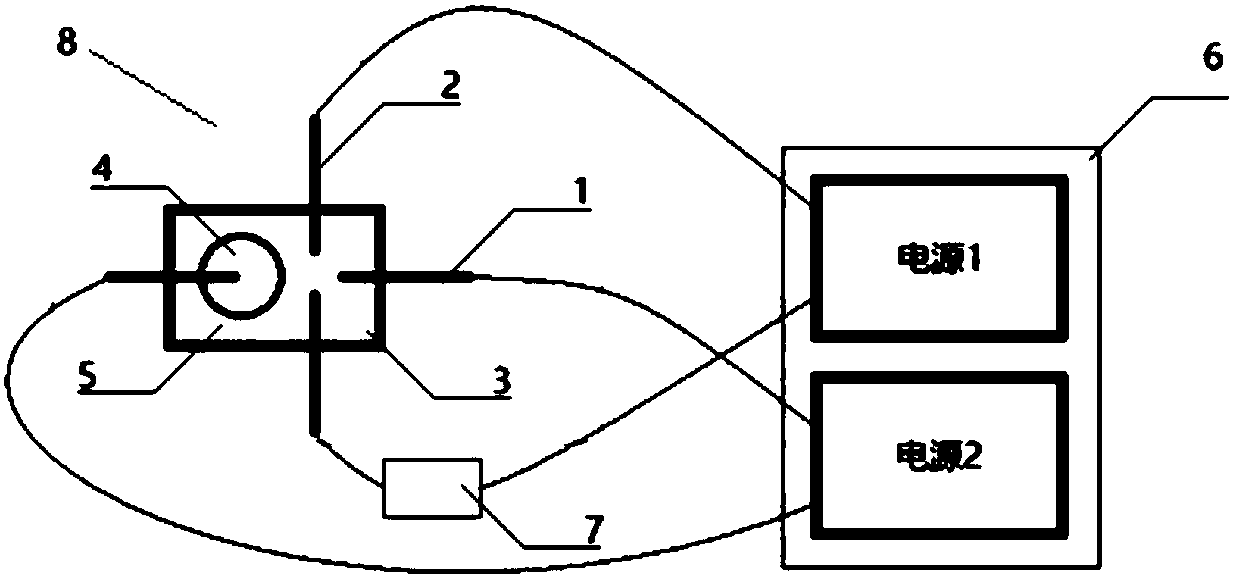

Magnetron driving power supply and control method

InactiveCN101072462ASmall filament currentImprove reliabilityAc-dc conversionApparatus with intermediate ac conversionSwitching frequencyHigh pressure

Owner:深圳市高斯宝电气技术有限公司

Digital improved verification system for analog control system of nuclear power plant

ActiveCN107577223AGuaranteed validityGuaranteed reliabilityElectric testing/monitoringNuclear powerControl system

The invention provides a digital improved verification system for an analog control system of a nuclear power plant. The system includes a simulation system body, an analog meter control system body,and a digitalizer control system body; the simulation system body is used for analogue simulation of real-time operation state of the nuclear power plant, the analog meter control system body is connected with the simulation system body and used for using the simulation system body as a control object and implementing various logic control functions in an analog control mode, and the digitalizer control system body is connected with the simulation system body and used for using the simulation system body as the control object, implementing various logic control functions same as these of the analog meter control system body in an analog control mode, and verifying the equivalence between the digital logic control functions and the corresponding logic control functions in the analog meter control system body. The system has the advantages that it can be ensured that the digital control system retains the functions and performance of an original simulation system after digital improvement.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +5

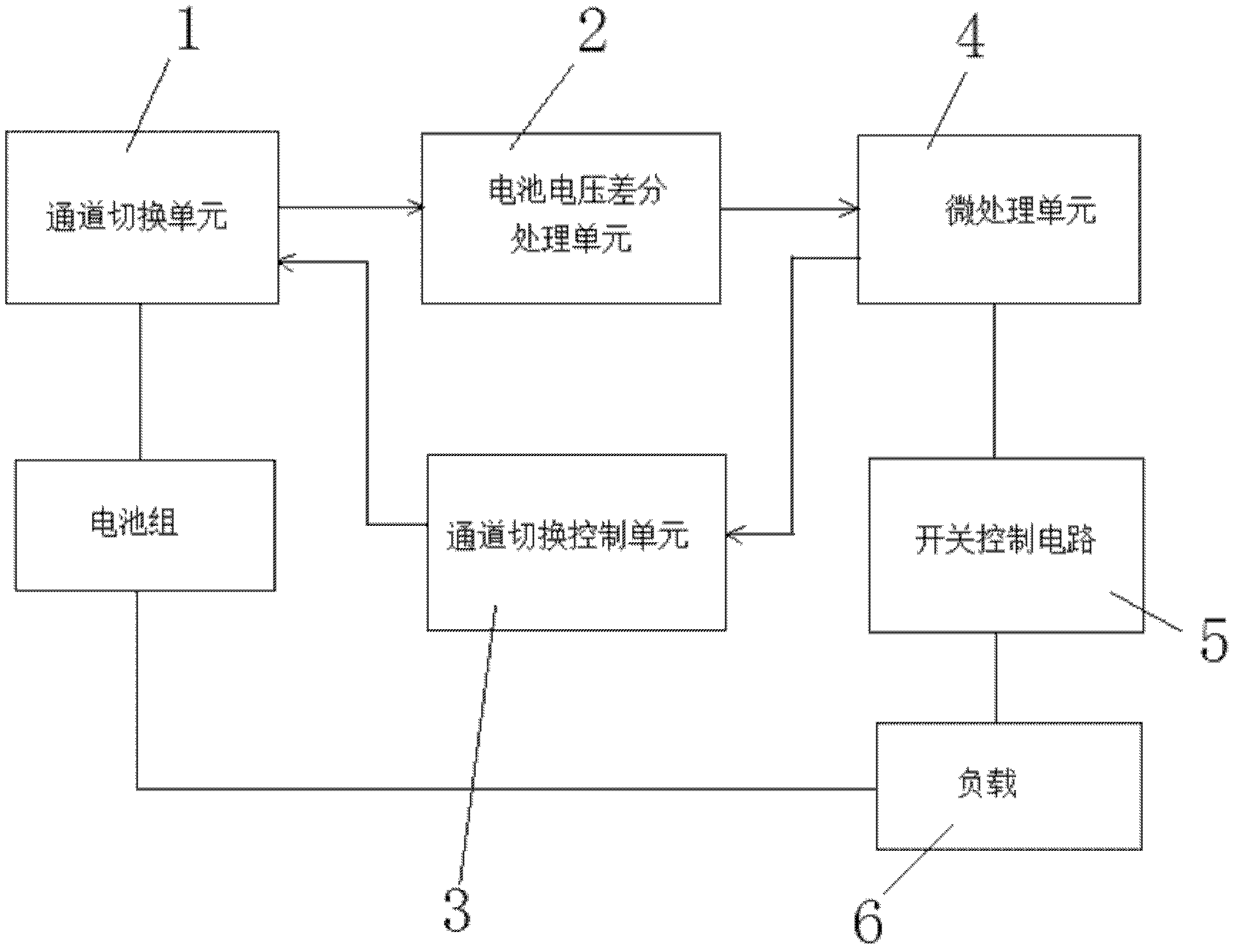

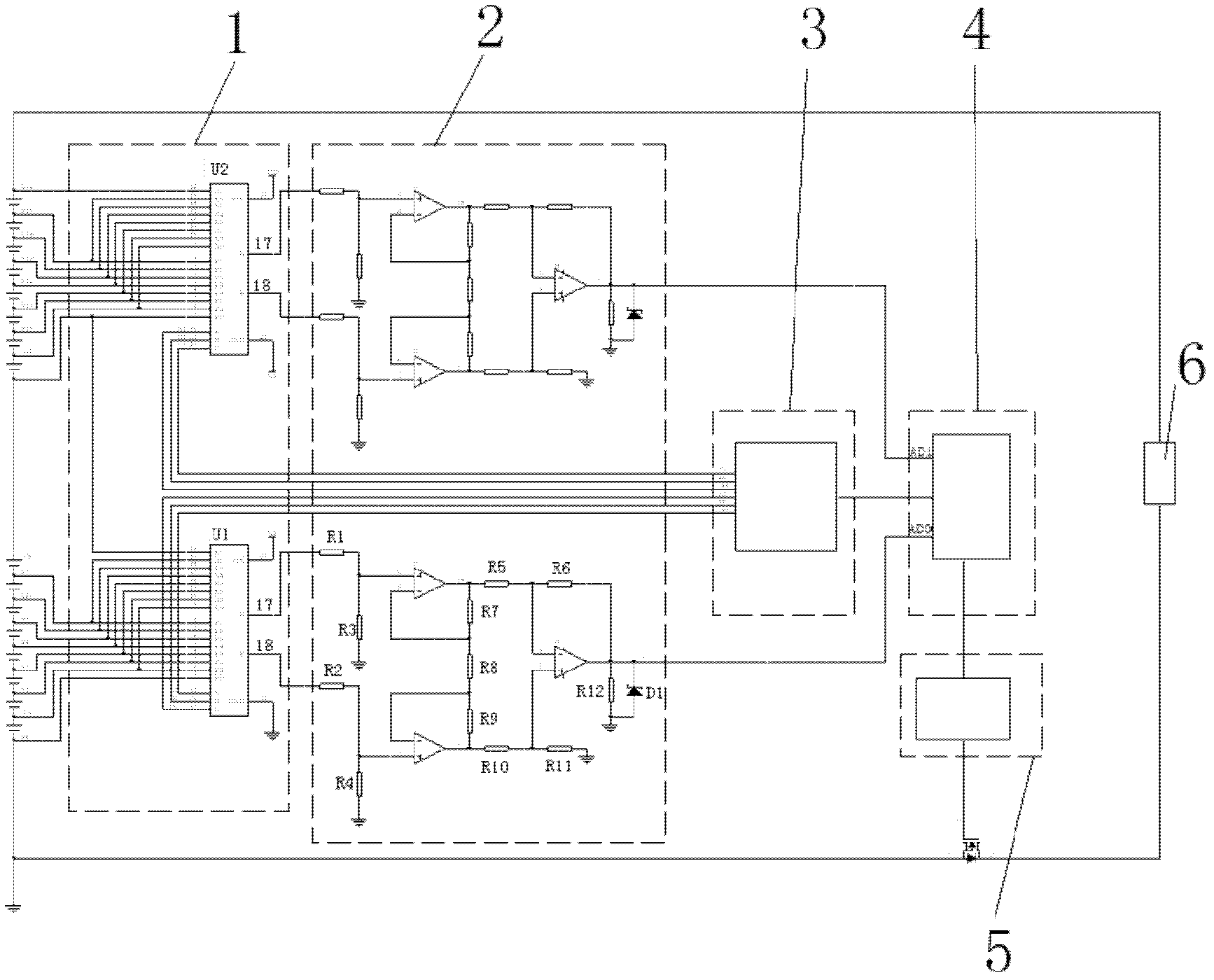

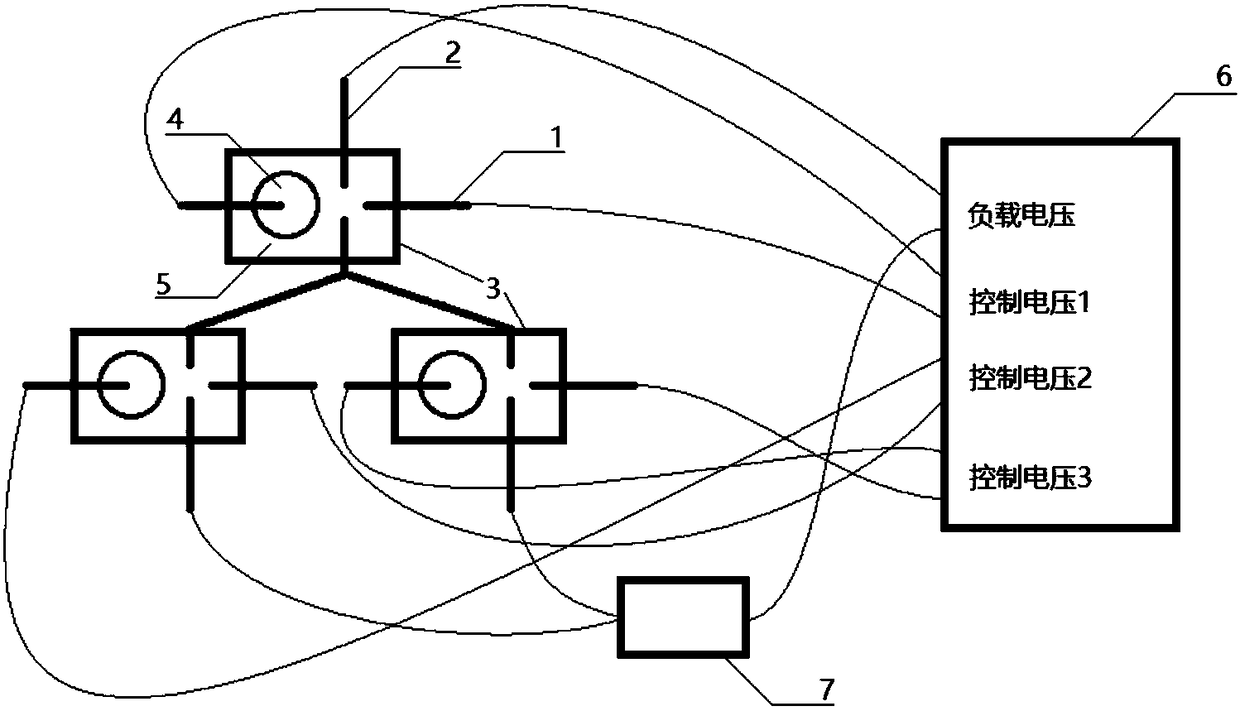

Multichannel battery sampling circuit and sampling method thereof

InactiveCN102495268AImprove detection accuracyImprove performanceCurrent/voltage measurementElectrical testingElectrical batteryPrice ratio

Owner:WUHU TIANYUAN AUTOMOBILE ELECTRON

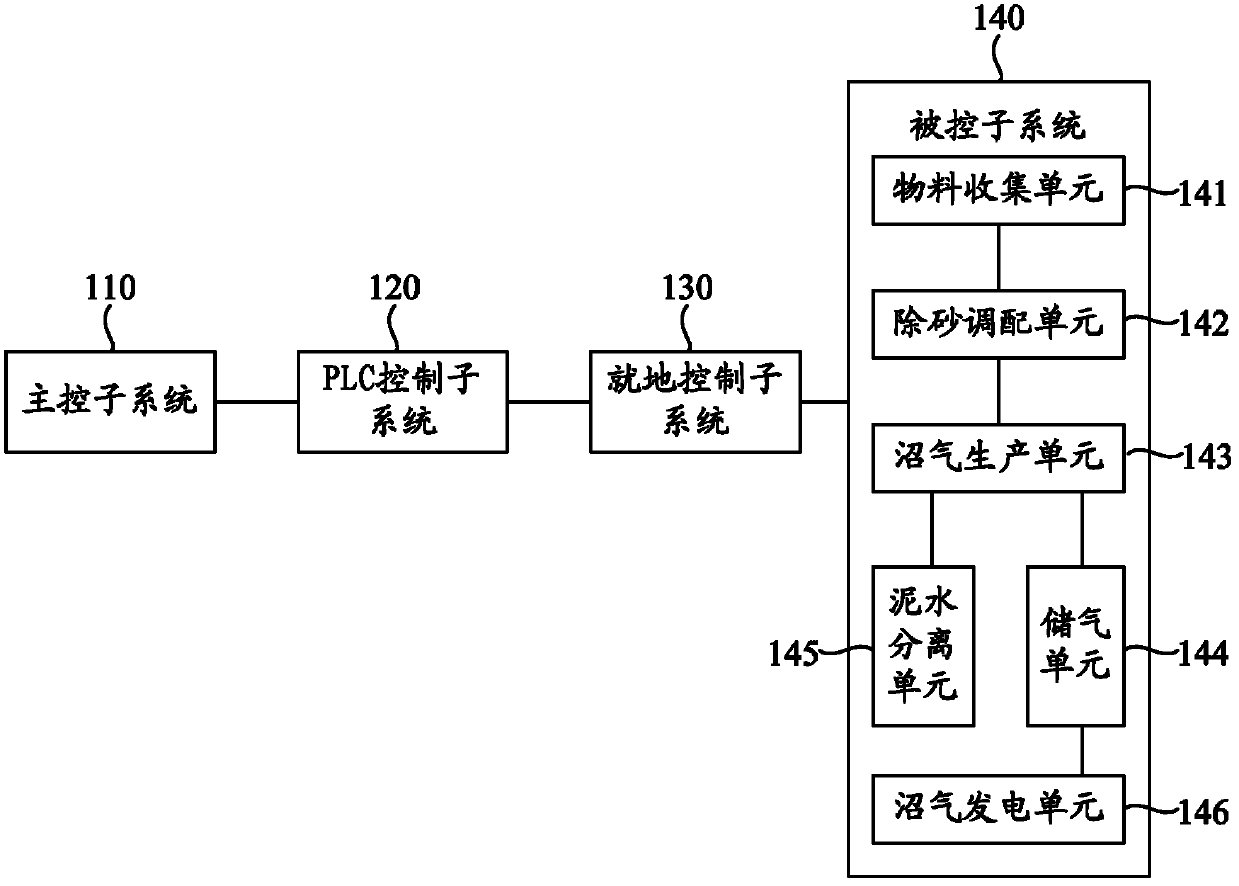

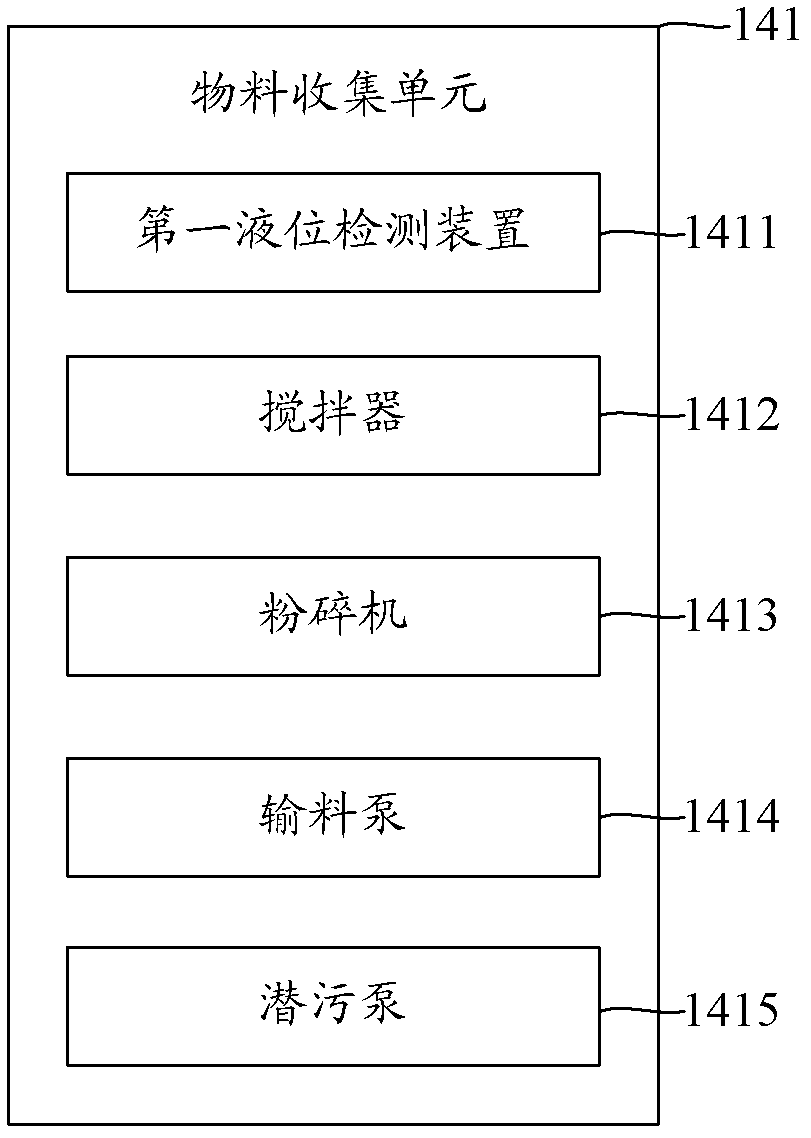

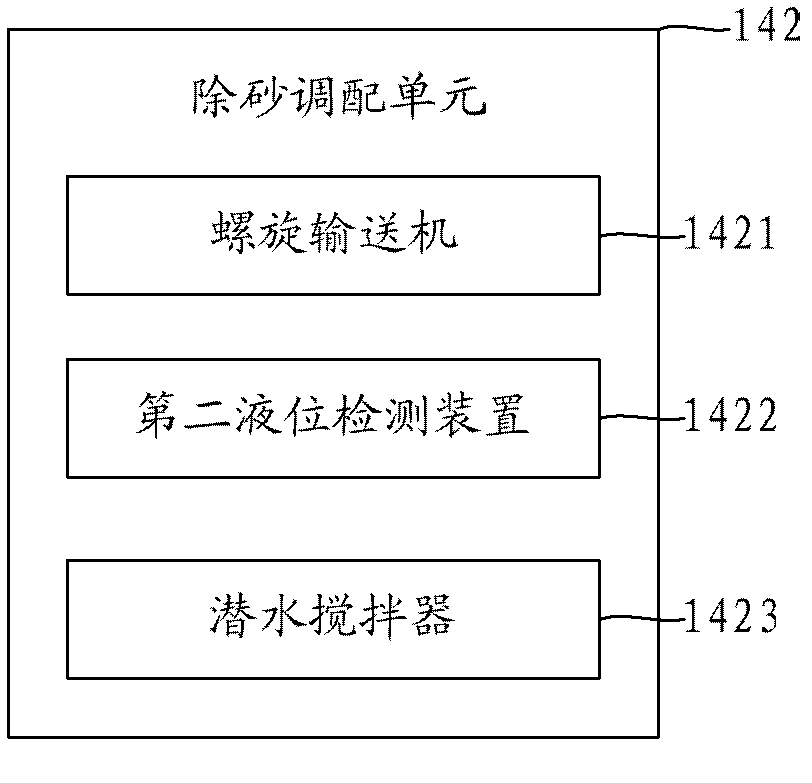

Biogas fermentation gas supply engineering control system

InactiveCN103305413AImprove real-time performanceImprove stabilityBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlEngineering controls

Owner:北京愿景宏能源环保科技发展有限公司

Camera system with low delay, less cache and controllable data output mode and method

ActiveCN109688314ALower latencyCompact handlingTelevision system detailsColor television detailsComputer hardwareComputer architecture

The invention relates to a camera system with low delay, less cache and a controllable data output mode. The camera system comprises a PLL module, a configuration register, a system and logic controlmodule, a photosensitive pixel acquisition control module, a photosensitive pixel matrix module, an analog signal processing module, an A / D conversion module, a digital image processing module, a buffer and an output interface module, wherein the configuration register, the system and logic control module, the photosensitive pixel acquisition control module, the photosensitive pixel matrix module,the analog signal processing module, the A / D conversion module, the digital image processing module, the buffer and the output interface module are sequentially connected; and the system and logic control module is also respectively connected with the PLL module, the A / D conversion module, the digital image processing module, the buffer and the output interface module. According to the scheme ofthe invention, by shrinking the units of image acquisition and output and simplifying the corresponding system logic control, the whole processing procedure is more compact, and the delay and cache space of the camera system and the whole system are reduced.

Owner:FUZHOU SHICHI TECH CO LTD

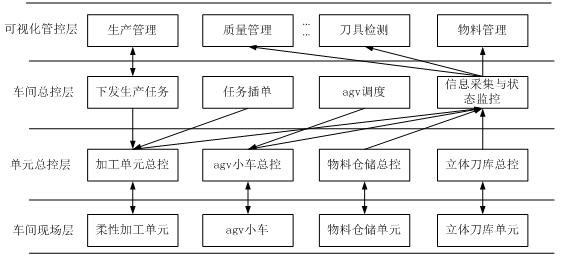

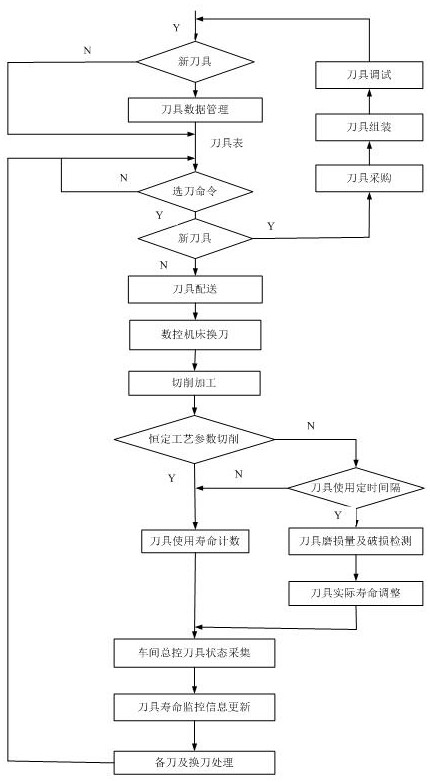

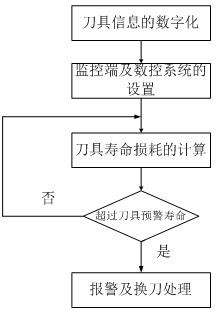

Intelligent monitoring system and method for service life of cutter

PendingCN113721575ATraceableFully grasp management informationTotal factory controlProgramme total factory controlControl layerOriginal data

Owner:SHENYANG INST OF TECH

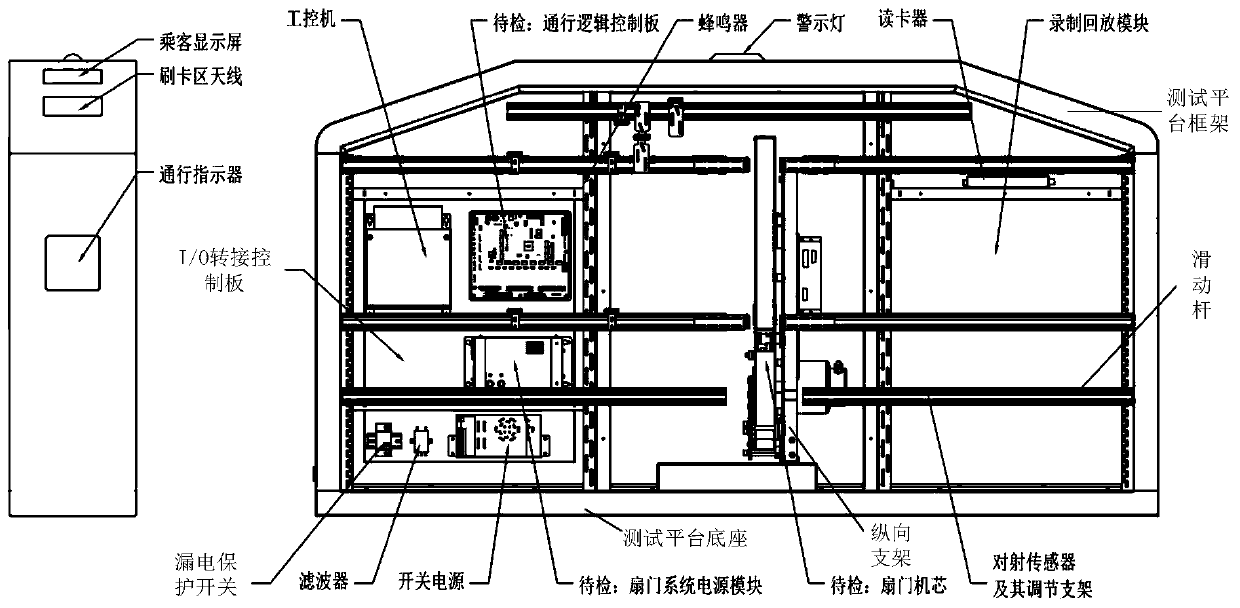

Terminal capable of simultaneously recording passage logic cases of multiple gate machines

PendingCN110109444AEasy to controlEnsure consistencyElectric testing/monitoringElectricityComputer module

Owner:南方银通(武汉)信息技术服务有限公司 +1

Combinable circuit structure

PendingCN108513437ASimple structureEasy to manufacturePrinted circuits structural associationsDielectricLiquid metal

Owner:BEIJING DREAM INK TECH CO LTD

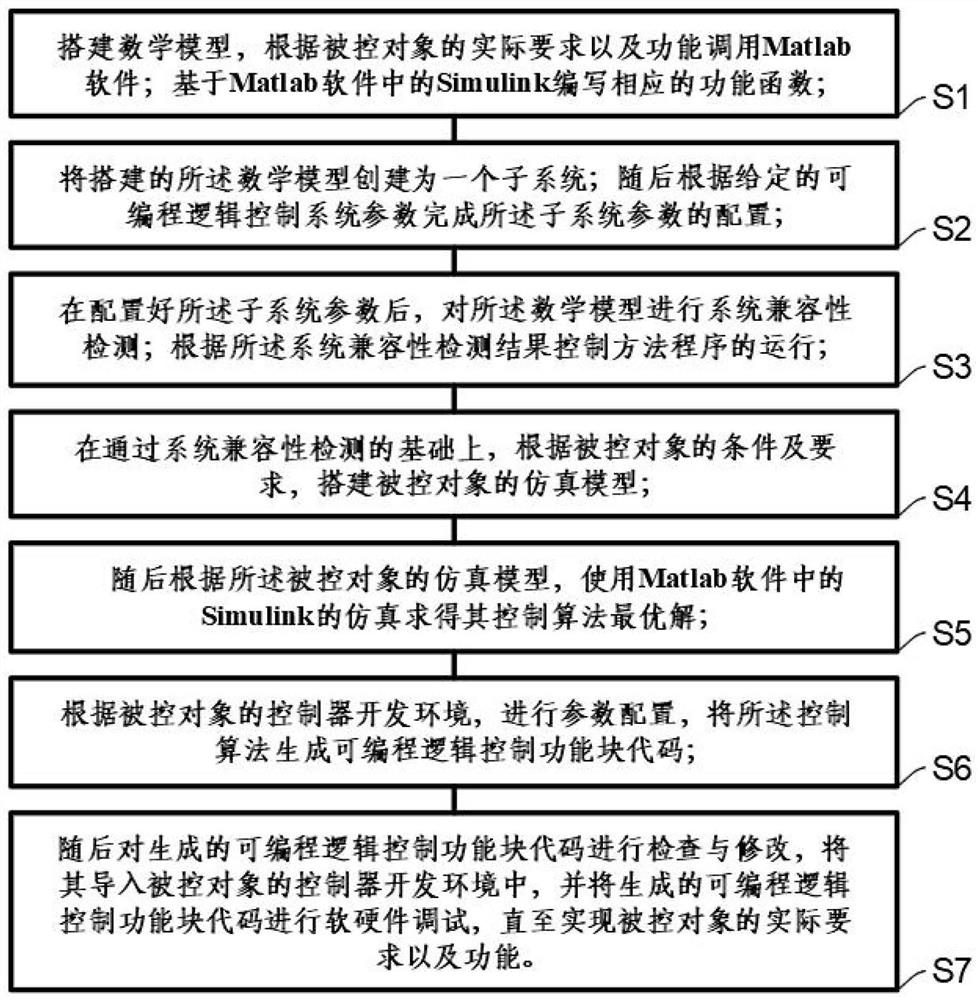

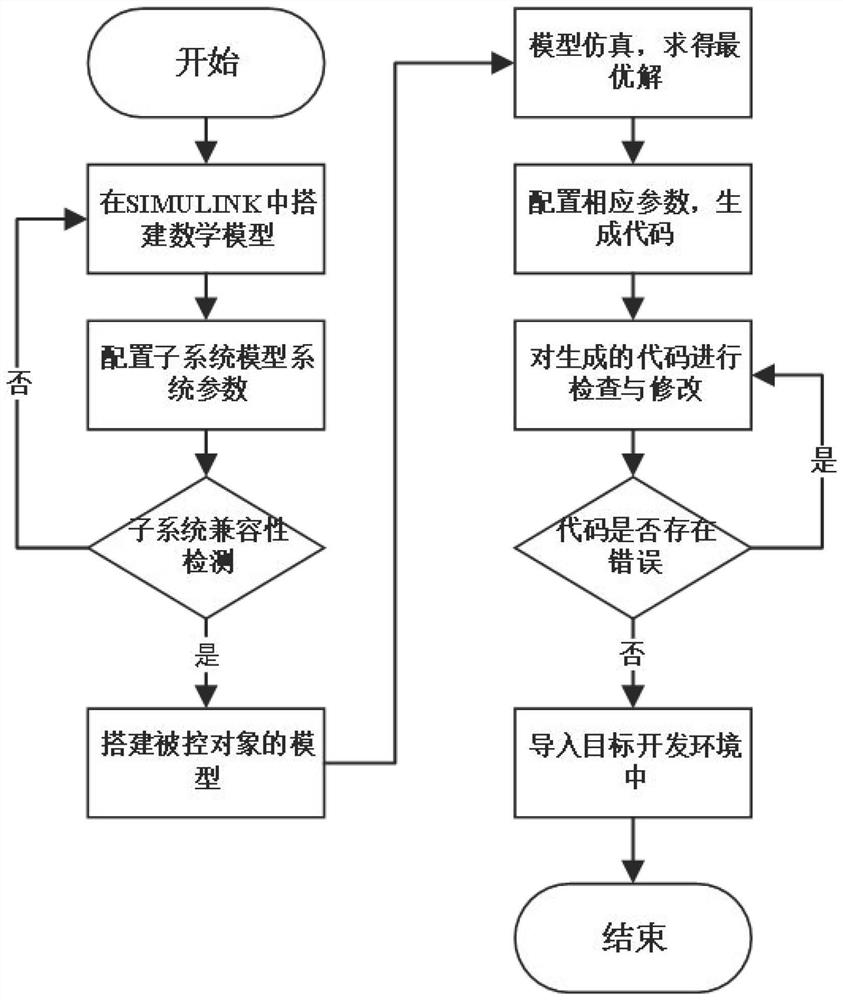

Method for rapidly generating programmable logic control function block codes

PendingCN114879590ATotal factory controlProgramme control in sequence/logic controllersPerformance functionSystems design

Owner:XIANGTAN UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap