Intelligent monitoring system and method for service life of cutter

A technology of tool life and monitoring system, which is applied in general control system, control/adjustment system, program control, etc., can solve the problems of no record of tool usage, affect the accuracy of tool life management, and tool life tracking, etc., to achieve reliable sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

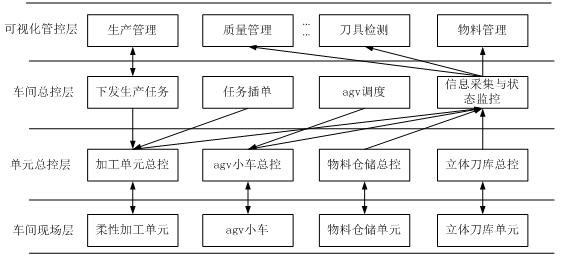

[0075] Such as figure 1 As shown, an intelligent tool life monitoring system according to an embodiment of the present invention includes:

[0076] (1) Workshop site layer, used to provide real-time site data for the system. The equipment on the workshop site level includes flexible processing units, AGV material transport trolleys, material storage units, tool storage units, etc. The data acquisition line is arranged on the on-site machine tool to obtain the online tool position and tool status of the machine tool in real time, which provides raw data for the visual management of tool monitoring. The present invention satisfies the network conn

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap