Double turntable light-sensitive cell liquid membrane reactor photocatalysis organic wastewater processing method

A technology of liquid membrane reactor and organic wastewater, applied in the direction of light water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of increasing energy consumption, increasing energy consumption, reducing energy consumption, etc., to achieve improved degradation efficiency, The effect of speeding up exchange updates and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Treatment of Dye Wastewater by Double Turntable Photocell Liquid Membrane Reactor with Different Cathode Materials

[0031] The treatment object is 20mg L -1 Rhodamine B (pH2.5, 1.0g / L Na 2 SO 4 ) to simulate dye wastewater. The waste water volume was 55ml.

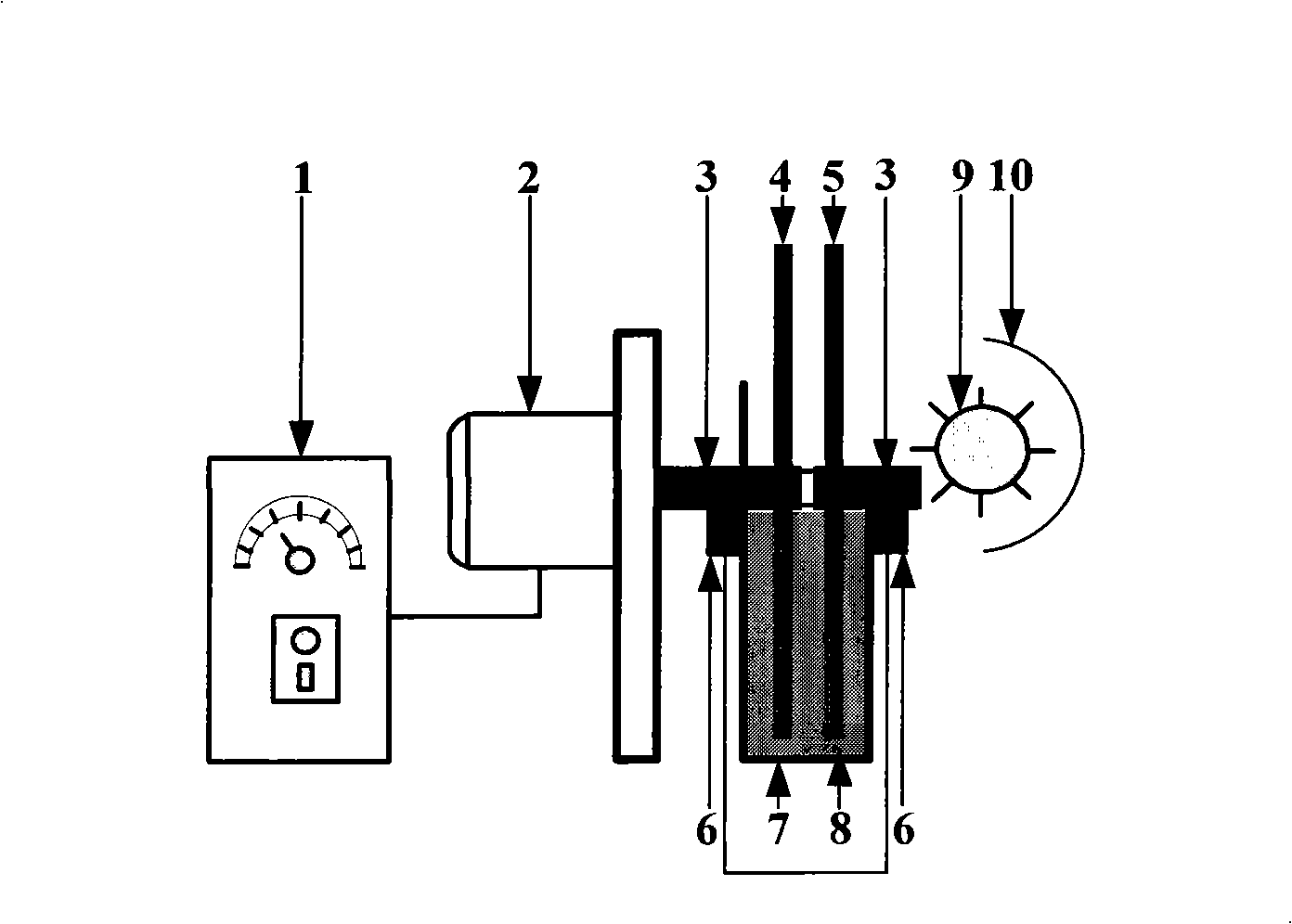

[0032] 1) Using a titanium disc as a substrate, the TiO 2 The photocatalyst is loaded on the substrate as a photoanode, respectively fixed on the rotating shaft with the Cu, Zn, Fe or C disc cathode to form a double rotating disc, and the rotating shaft of the rotating disc is connected with the motor.

[0033] 2) Place the turntable in the semi-circular arc reaction tank, the rotating shaft of the turntable is at the water surface of the waste water, so that the lower half of the turntable is immersed in the waste water, and the photoanode and cathode turntables are connected by wires through the carbon brush connected to the rotating shaft.

[0034] 3) Start the motor, and control the rotation speed o

Embodiment 2

[0039] Example 2TiO 2 Treatment of dye wastewater with different concentrations in a liquid membrane reactor with Ti and Cu double-rotating disk photocells

[0040] The treatment object is Rhodamine B of different concentrations (pH2.5, 1.0g / L Na 2 SO 4 ) to simulate dye wastewater. The waste water volume was 55ml.

[0041] 1) Using a titanium disc as a substrate, the TiO 2 The photocatalyst is loaded on the substrate as a photoanode, and is fixed on the rotating shaft together with the Cu disc cathode to form a double rotating disc, and the rotating shaft of the rotating disc is connected with the motor.

[0042] 2) Place the turntable in the semi-circular arc reaction tank, the rotating shaft of the turntable is at the water surface of the waste water, so that the lower half of the turntable is immersed in the waste water, and the photoanode and cathode turntables are connected by wires through the carbon brush connected to the rotating shaft.

[0043] 3) Start the motor

Embodiment 3

[0049] Example 3TiO 2 / Stainless steel and Cu double turntable photocell liquid membrane reactor to treat different concentrations of dye wastewater

[0050] The treatment object is Rhodamine B of different concentrations (pH2.5, 1.0g / L Na 2 SO 4 ) to simulate dye wastewater. The waste water volume was 55ml.

[0051] 1) Using a stainless steel disc as a substrate, the TiO 2 The photocatalyst is loaded on the substrate as a photoanode, and is fixed on the rotating shaft together with the Cu disc to form a double turntable, and the rotating shaft of the turntable is connected with the motor.

[0052] 2) Place the turntable in the semi-circular arc reaction tank, the rotating shaft of the turntable is at the water surface of the waste water, so that the lower half of the turntable is immersed in the waste water, and the photoanode and cathode turntables are connected by wires through the carbon brush connected to the rotating shaft.

[0053] 3) Start the motor, and control

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap