Endless metal ring and method of producing the same

a metal ring and end-less technology, applied in the field of end-less metal ring, can solve the problems of reducing the fatigue strength of endless metal ring, deteriorating the fatigue strength of titanium nitride, etc., and achieve the effect of reducing the constriction of welded parts and excellent fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

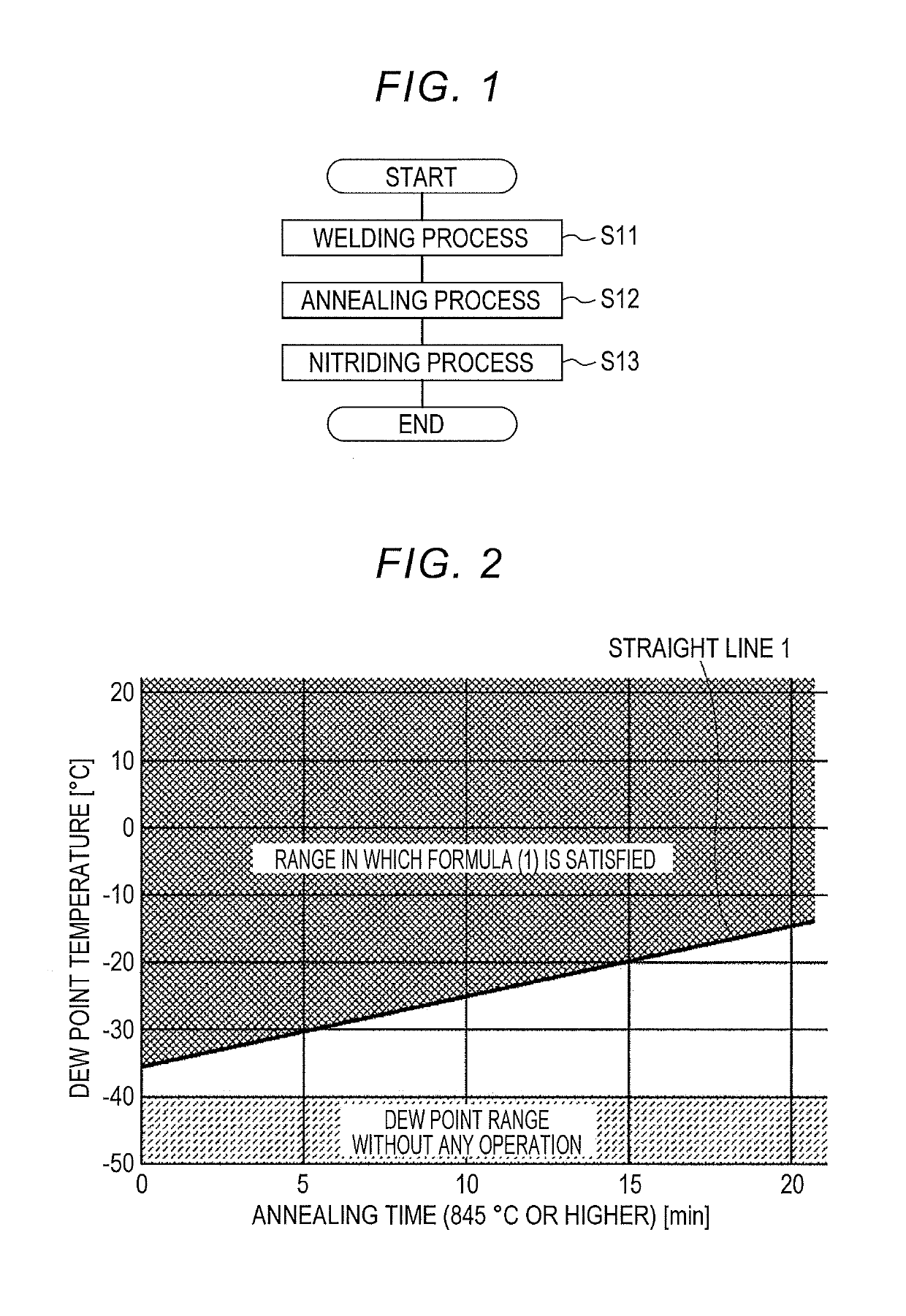

Production of Endless Metal Ring

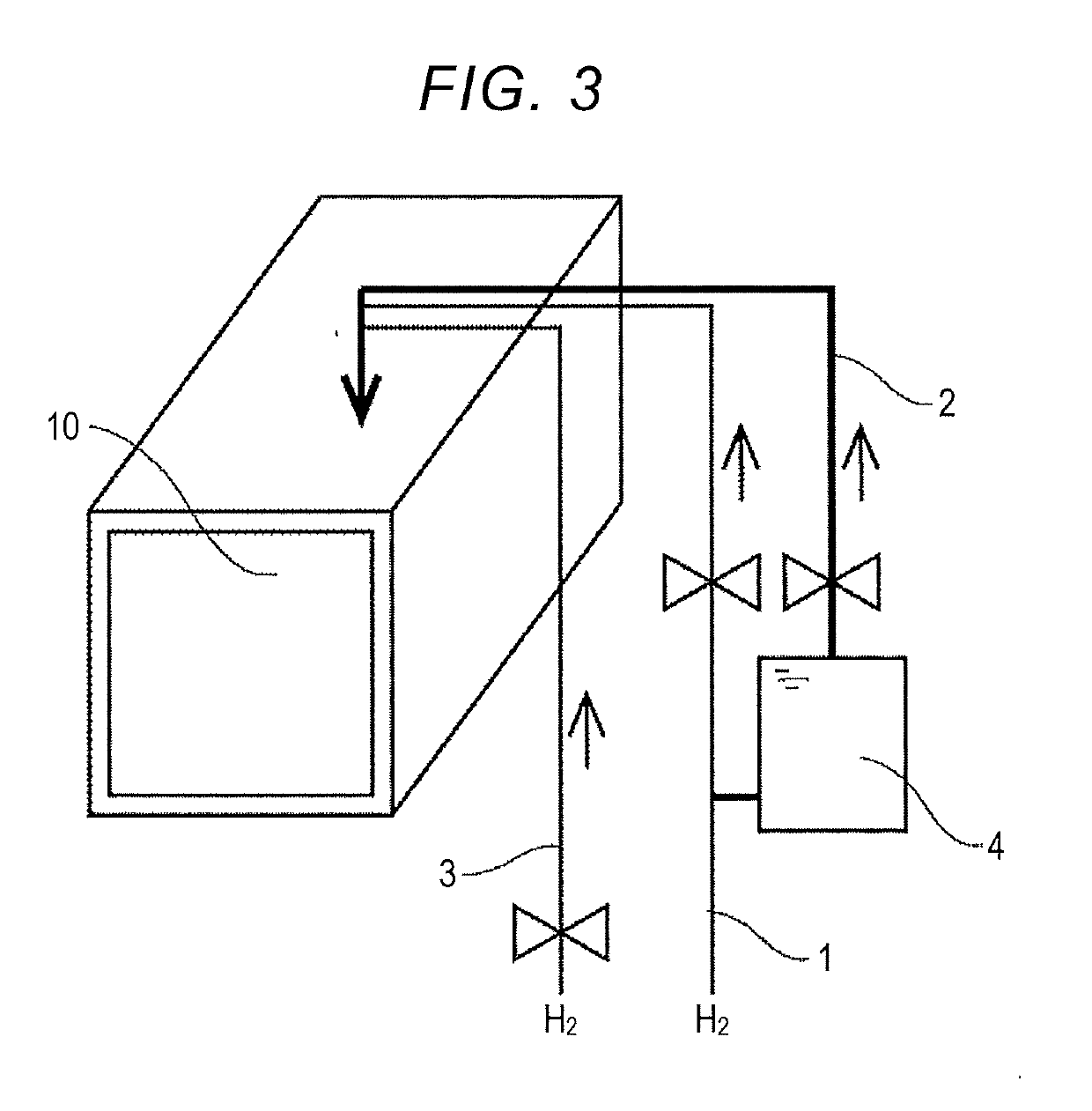

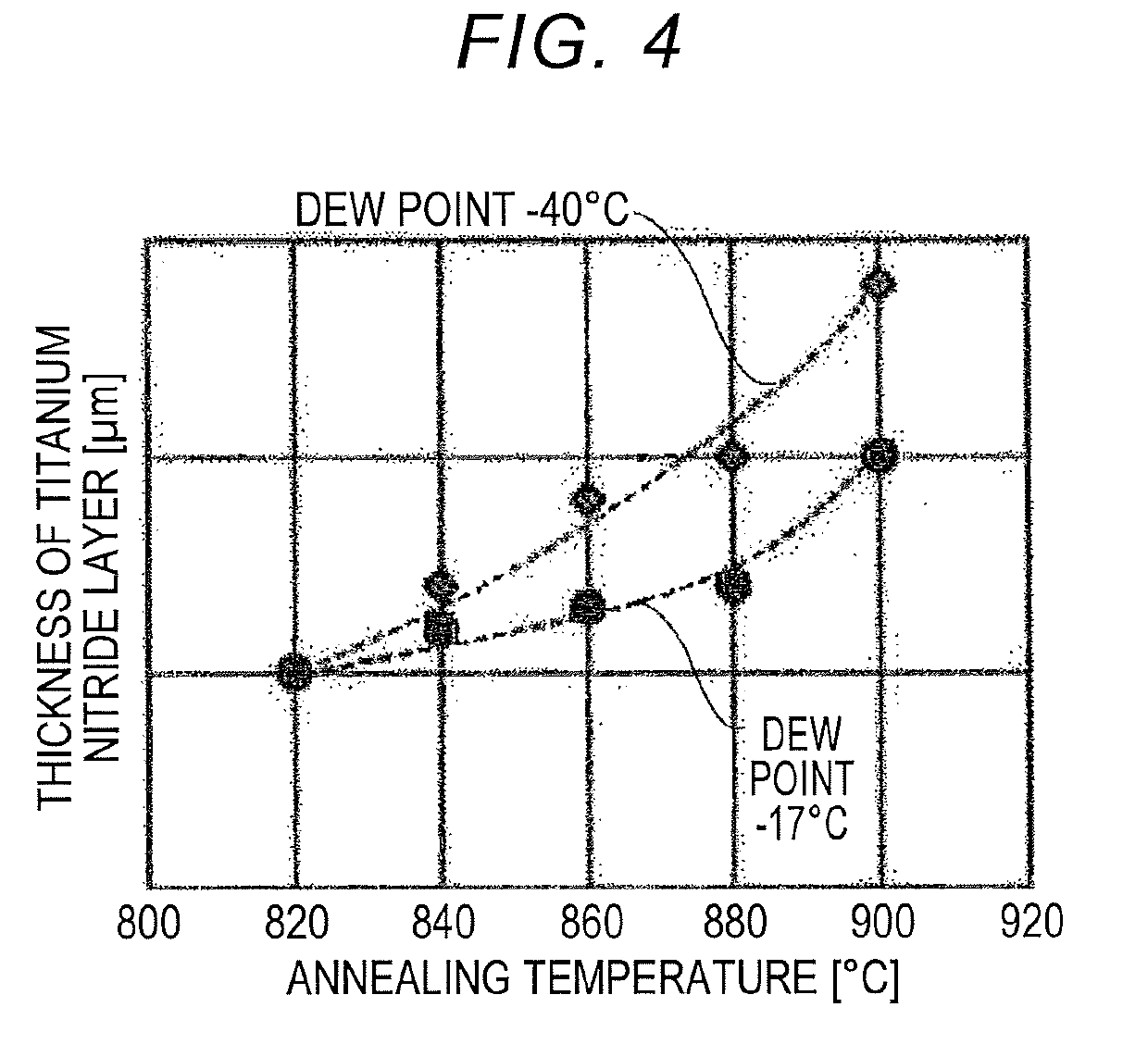

[0037]An endless metal ring was produced using a maraging steel plate including 5.75 mass % to 6.05 mass % of molybdenum, 12.0 mass % to 17.0 mass % of cobalt, 17.0 mass % to 20.0 mass % of nickel, 0.4 mass % to 0.5 mass % of titanium, and 0 mass % to 0.15 mass % of aluminum with the remainder being made up of iron and inevitable impurities according to the production method described above. In the annealing process, a flow rate of nitrogen gas through a water supply source was controlled, and annealing was performed at 880° C. for 15 minutes while a dew point temperature was adjusted to −20° C. The thickness of the titanium nitride layer in the obtained endless metal ring was 2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap