Novel heat energy recovery device

A new type of heat energy recovery technology, applied in indirect heat exchangers, transportation and packaging, fluid heaters, etc., can solve problems such as blockage of ventilation pipes, limited recovery effect, and limit the performance and scope of application of recovery devices, to ensure normal The effect of operation and full recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

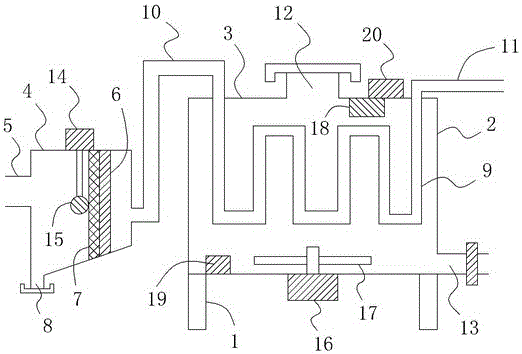

[0013] Such as figure 1 As shown, a new type of heat energy recovery device includes a bracket 1 and a water tank 2 located on the bracket 1. A tank cover 3 is also provided on the top of the water tank 2, and a filter cavity 4 is provided on the left side of the water tank 2. After filtering The left side wall of the cavity 4 is connected with an air intake pipe 5, and the right side wall of the filter cavity 4 is provided with a cavity air outlet, and a vertically arranged dividing plate 6 is also provided inside the filter cavity 4. The plate 6 is evenly provided with a plurality of partition through holes, and a filter screen 7 close to the partition 6 is also provided on the left side of the partition 6, and a cleaning port 8 is also provided at the bottom left end of the filter cavity 4, A cover is also provided at the cleaning port; at least one S-shaped heat dissipation pipe 9 is also provided inside the water tank 2, and the air inlet of the S-shaped heat dissipation pip

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap