Automatic filter membrane replacement device

A technology of automatic replacement and filter membrane, applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low efficiency, time-consuming and laborious, and achieve the effect of avoiding shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

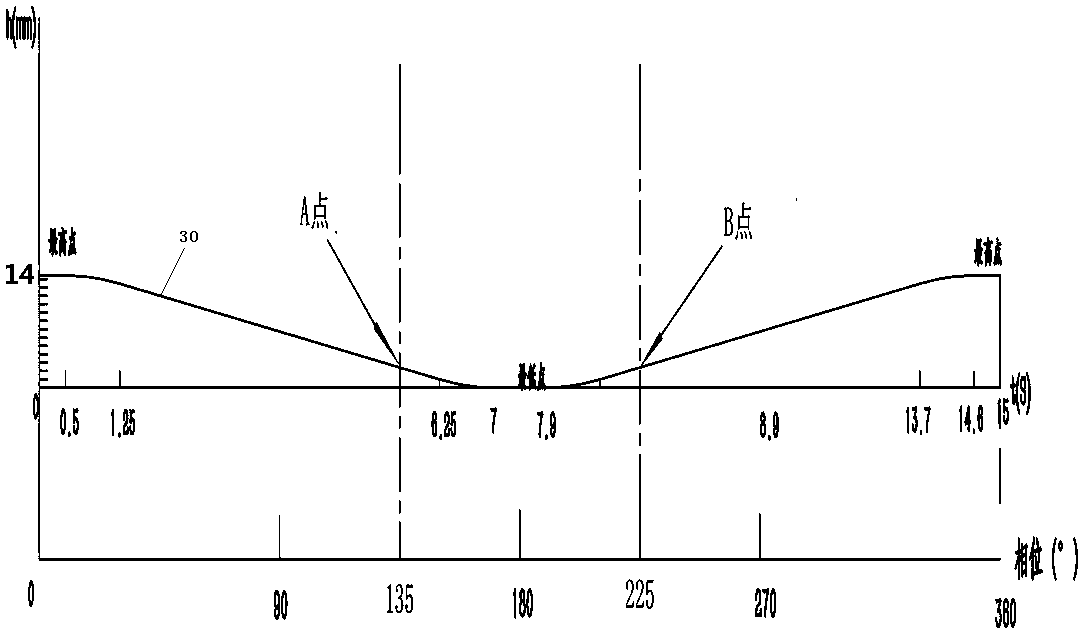

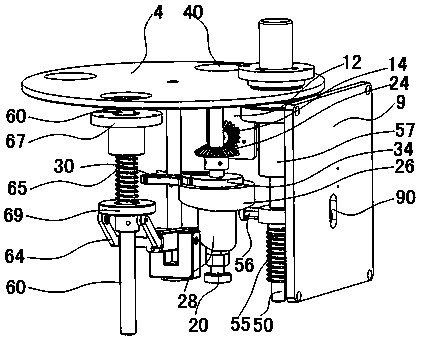

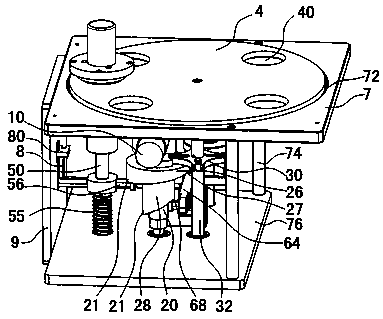

[0056] Such as Figure 1 to Figure 4 shown, and refer to Figure 5 to Figure 12, The filter membrane automatic replacement device of the present invention includes a drive mechanism 1 , a cam mechanism 2 , a Maltese cross movement 3 , a turntable 4 , a sampling clamping mechanism 5 and a filter membrane holding mechanism 6 . The driving mechanism 1 includes a motor 10, a reduction box 12 and a driving helical gear 14; the cam mechanism 2 includes a camshaft 20, a driven helical gear 24 fixed on the camshaft 20 and drivingly engaged with the driving helical gear 14, and a driven helical gear 24 fixed on the camshaft 20. The upper cam 26 and the lower cam 28; the Maltese cross movement 3 includes a Malta 30 with a slot 31, a rotating shaft 32 that fixes the Malta 30, a notched cam 34 and a pin 36 that match the Malta 30, wherein the notched cam 34 and The

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap