Wheel-sheathed wheel anti-skid and anti-sink track

A wheel-wrapped and tracked technology, applied in anti-skid devices, vehicle parts, tire parts, etc., can solve the problems of difficult driving safety, weak anti-skid ability, wear and tear of road surface and tires, and improve the ability to prevent getting stuck in mud , enhanced safety and reliability, the effect of increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

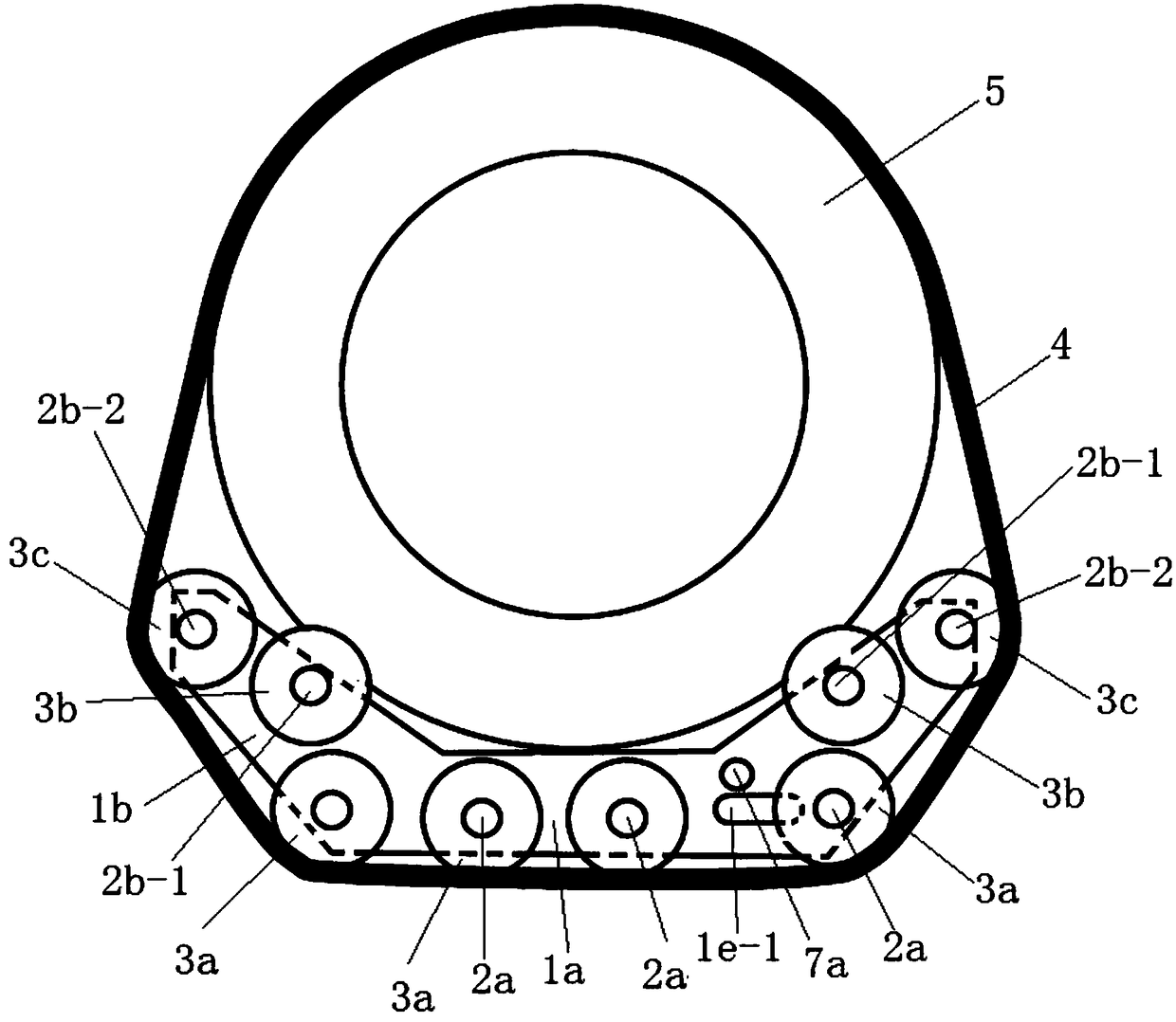

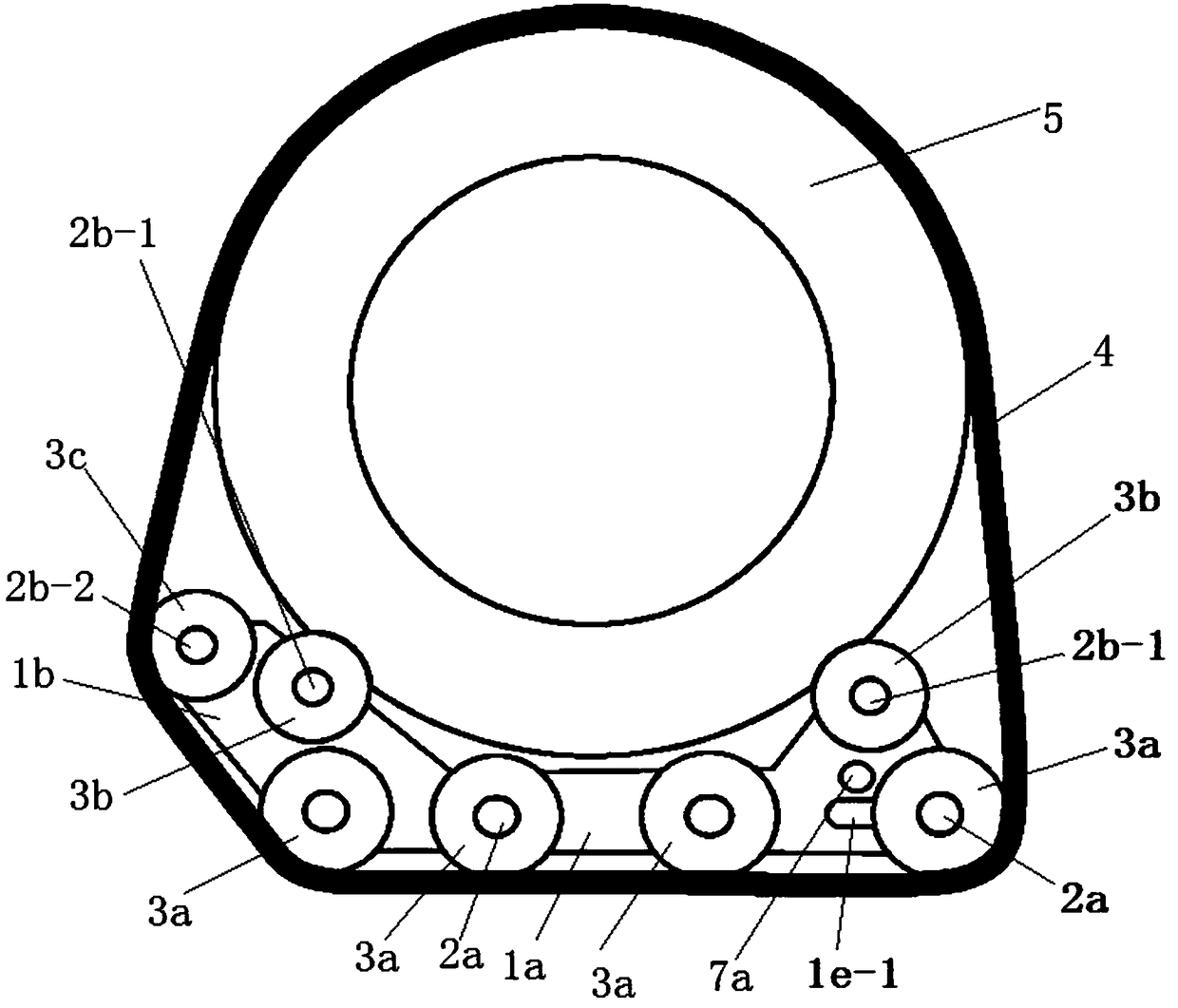

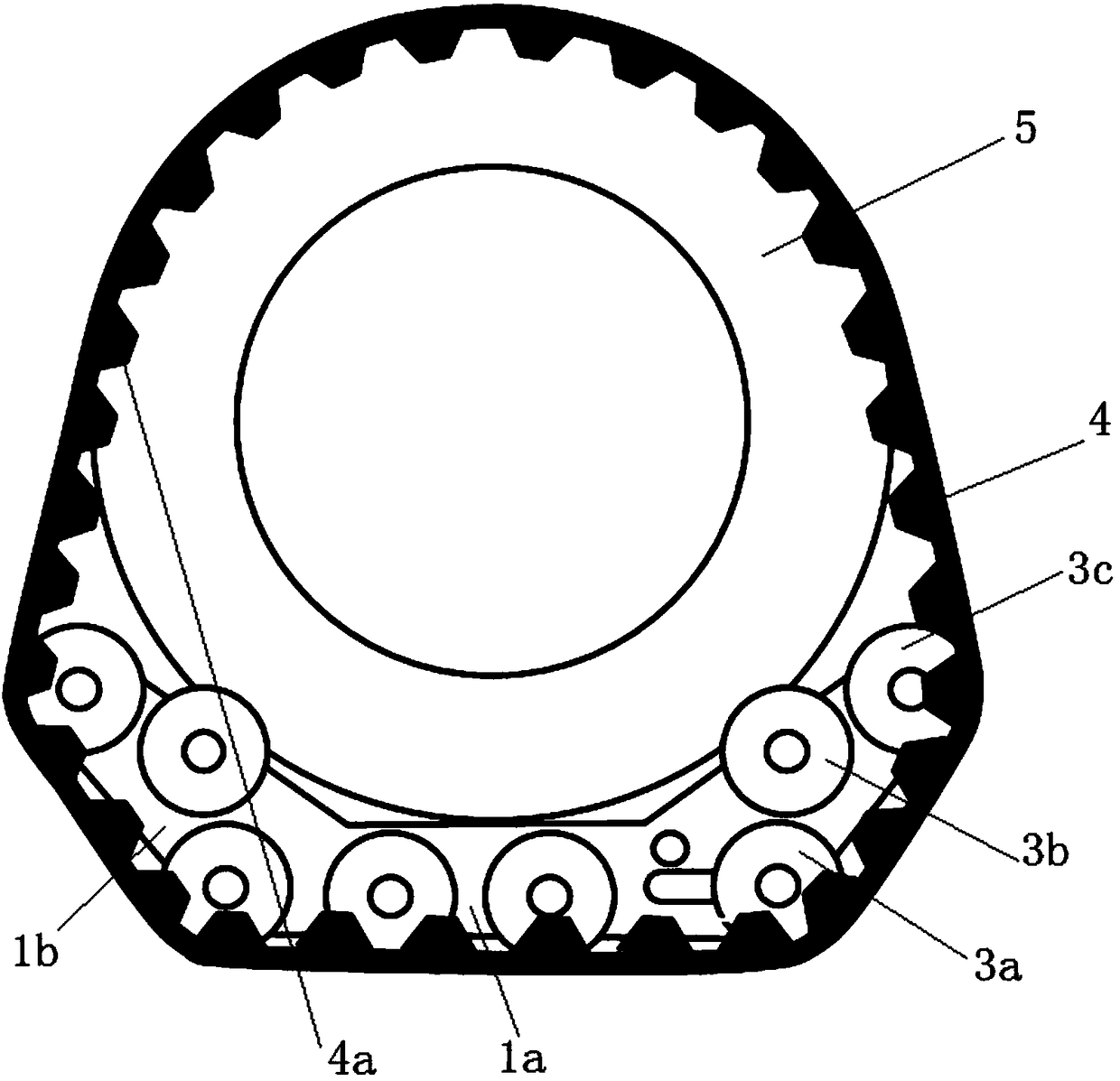

[0025] like figure 1 , figure 2 , image 3 The illustrated anti-skid and anti-sag crawler for wrapping wheels includes a trough-shaped frame body with the flaring upwards carrying the tire 5, a set of transverse shafts crossing the trough-shaped frame body, and rotating shafts symmetrically installed at both ends of each transverse shaft. Wheel, the crawler belt 4 that is wrapped in tire and trough frame body and runner periphery.

[0026] The set of transverse shafts that traverse the trough-shaped frame body includes at least 3 load-bearing wheel transverse shafts 2a that pass through and are located at the bottom plate 1a of the trough-shaped frame body, and the side plate transverse shafts that pass through the side plates 1b of the two sides of the trough respectively. ; The runners mounted on both ends of the horizontal axis of the bottom plate are load-bearing wheels 3a. The bottom of the rim of the load-bearing wheel is lower than the bottom surface of the trapezoidal

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap