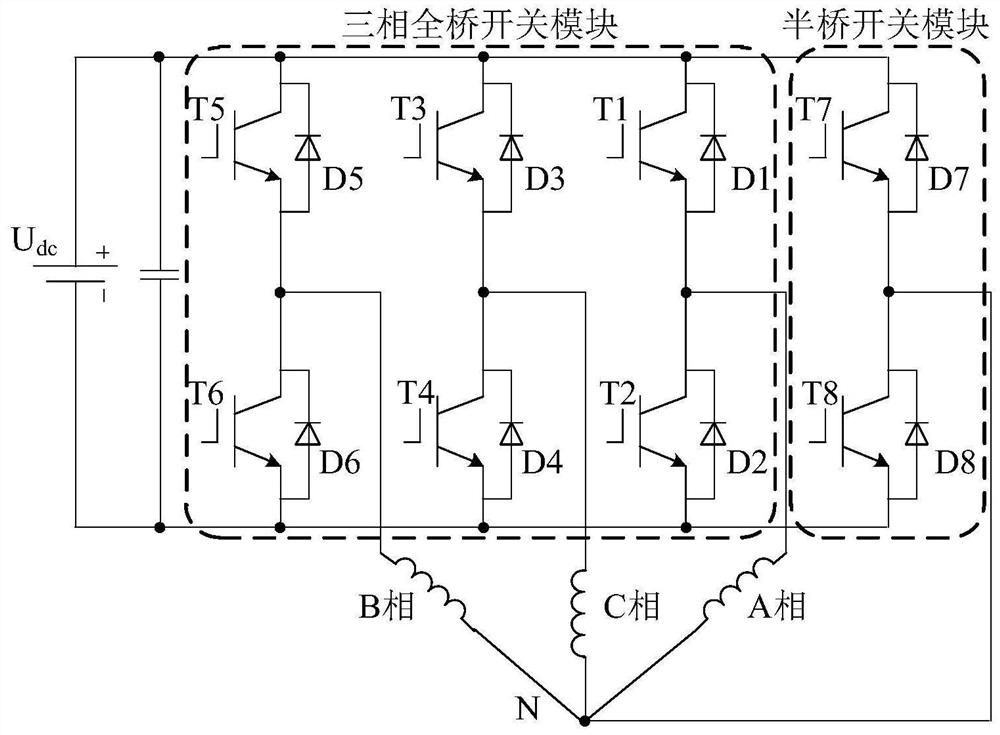

Switched reluctance motor torque control method and modular power converter thereof

A technology of switched reluctance motor and power converter, which is applied in the direction of AC motor control, conversion of AC power input to DC power output, and output power conversion devices, etc. Device burden and other issues, to avoid the effect of free response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the accompanying drawings and embodiments.

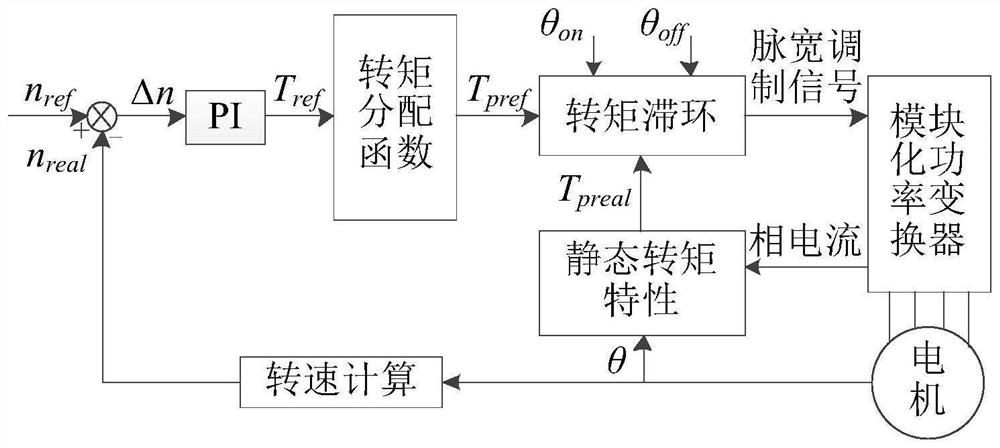

[0014] The technical solution of the present invention is described in detail below with reference to the accompanying drawings and specific examples. The steps of the torque control method for a switched reluctance motor provided by the present invention are:

[0015] The torque control method of the switched reluctance motor driven by the modular power converter includes a speed loop and a torque loop, the outer loop is the speed loop, and the inner loop is the torque loop; the input of the speed loop is the set reference speed n ref and the measured actual speed n real , by n ref -n real Obtain the speed error Δn, take the speed error Δn as the input, and obtain the total reference torque T through PI control ref ;The input of the torque loop is T ref , the actual torque T of each phase preal and the opening angle θ on and the turn-off angle θ off

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap