Elliptical Polarizer and Vertical Alignment Type Liquid Crystal Display Device Comprising the Same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

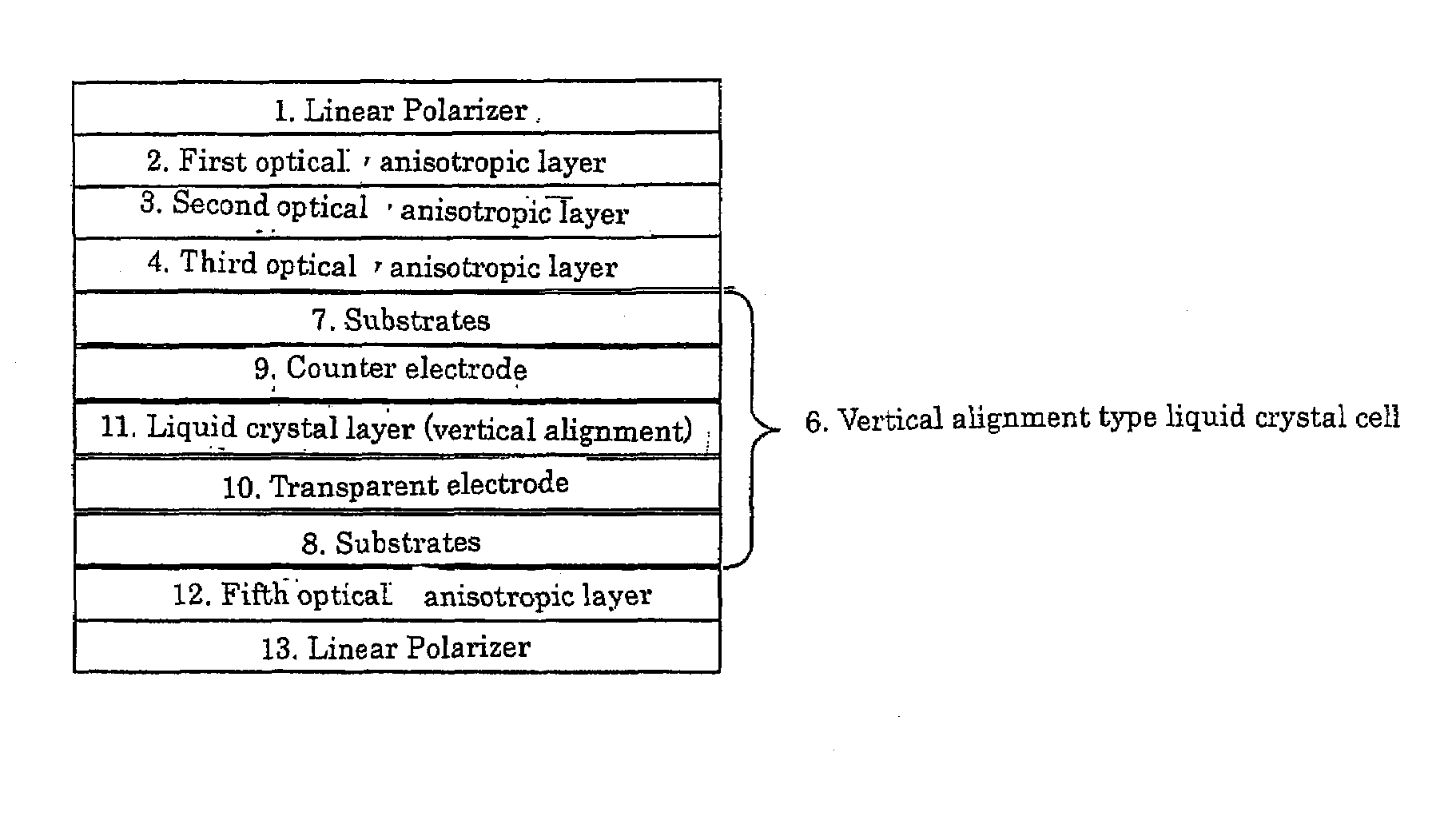

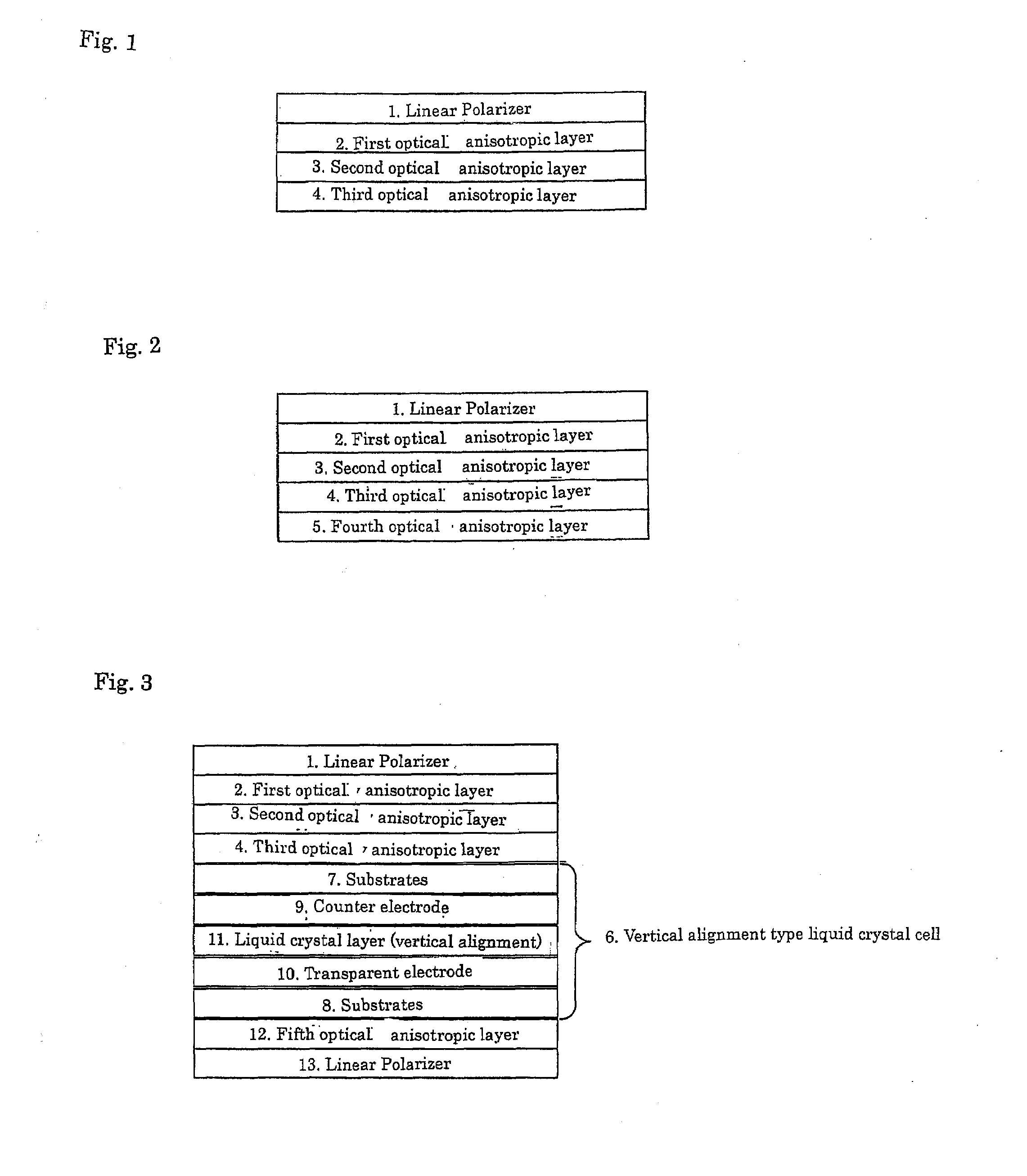

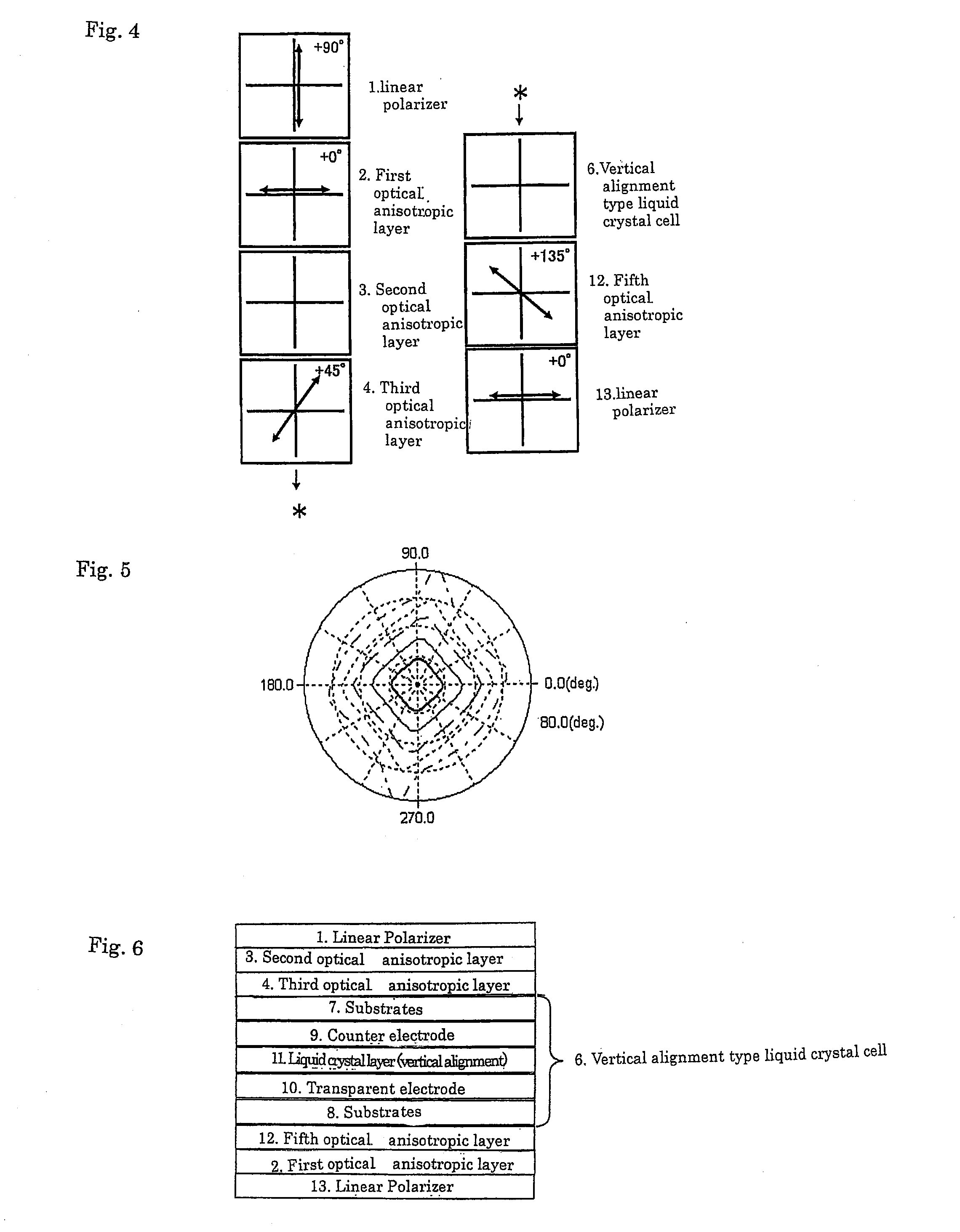

[0294]1, 13: linear polarizer, 2, 15: first optical anisotropic layer, 3, 16: second optical anisotropic layer, 4: third optical anisotropic layer, 5: fourth optical anisotropic layer, 12: fifth optical anisotropic layer, 7,8: substrate, 10: transparent electrode, 9: counter electrode, 15: reflective electrode, 11: liquid crystal layer (vertical alignment), 6: vertical alignment type liquid crystal cell, 14: transflective vertical alignment type liquid crystal cell

APPLICABILITY IN THE INDUSTRY

[0295]The vertical alignment type liquid crystal display device of the present invention is bright in images and capable of displaying images of high contrast in all the directions and thus has a large industrial value.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap