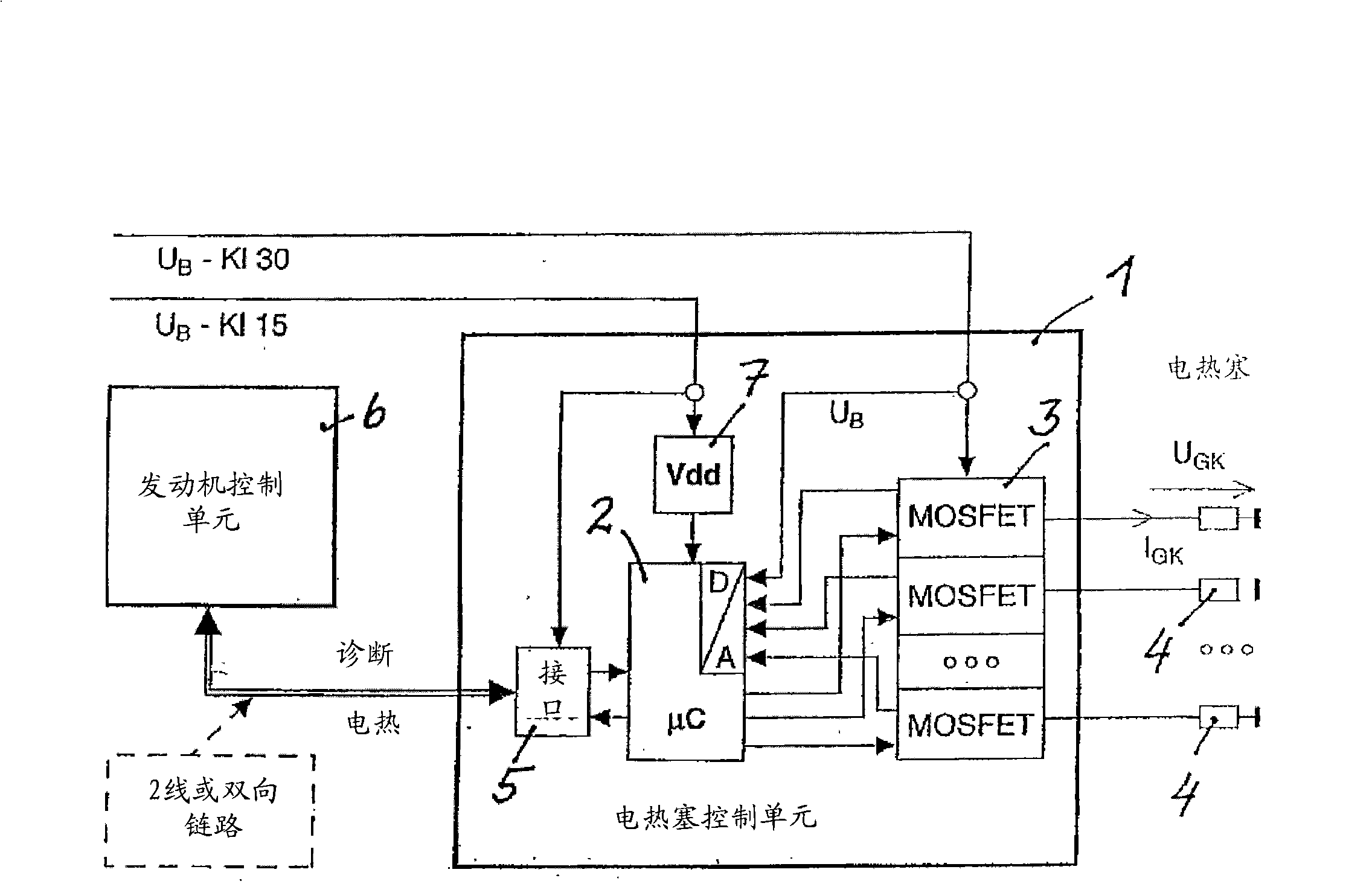

Method for controlling a group of glow plugs in a diesel engine

A diesel engine and glow plug technology, which is applied to the incandescent ignition of the engine, engine ignition, engine control, etc., can solve the problems of non-use and undesired temperature of the glow plug, and achieve the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following applies all said three solutions to the object of the invention:

[0039] The term relative pulse width is used here to describe the pulse width in relation to the length of the modulation period. Preferably, the period is constant and only the pulse width is varied. However, it is also possible to keep the pulse width constant and vary the period.

[0040] Another advantage of the invention can be seen in fact that, in addition to the resistance of the glow plugs, other parameters influencing the temperature of the individual glow plugs are likewise used as input parameters by pulse modulation for the work, thereby being used for the work of each glow plug. One such parameter, advantageously used as input parameter for said pulse width modulation control, is the voltage of the DC power supply to said glow plugs, in particular the voltage of the battery of a vehicle equipped with a diesel engine. The voltage will vary with the current load, the temperature

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap