Frequency-conversion high-speed permanent magnet shield pump

A shielded pump, permanent magnet technology, applied in non-variable-capacity pumps, pumps, pump devices, etc., can solve the problem that the permanent magnet synchronous motor with variable frequency speed regulation cannot achieve absolutely no leakage, and cannot be used to transport precious liquids with chemicals, etc. The problem of high-speed operation of the permanent magnet canned pump cannot be realized, and the effect of improving the efficiency of the unit, good maintainability and light weight can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

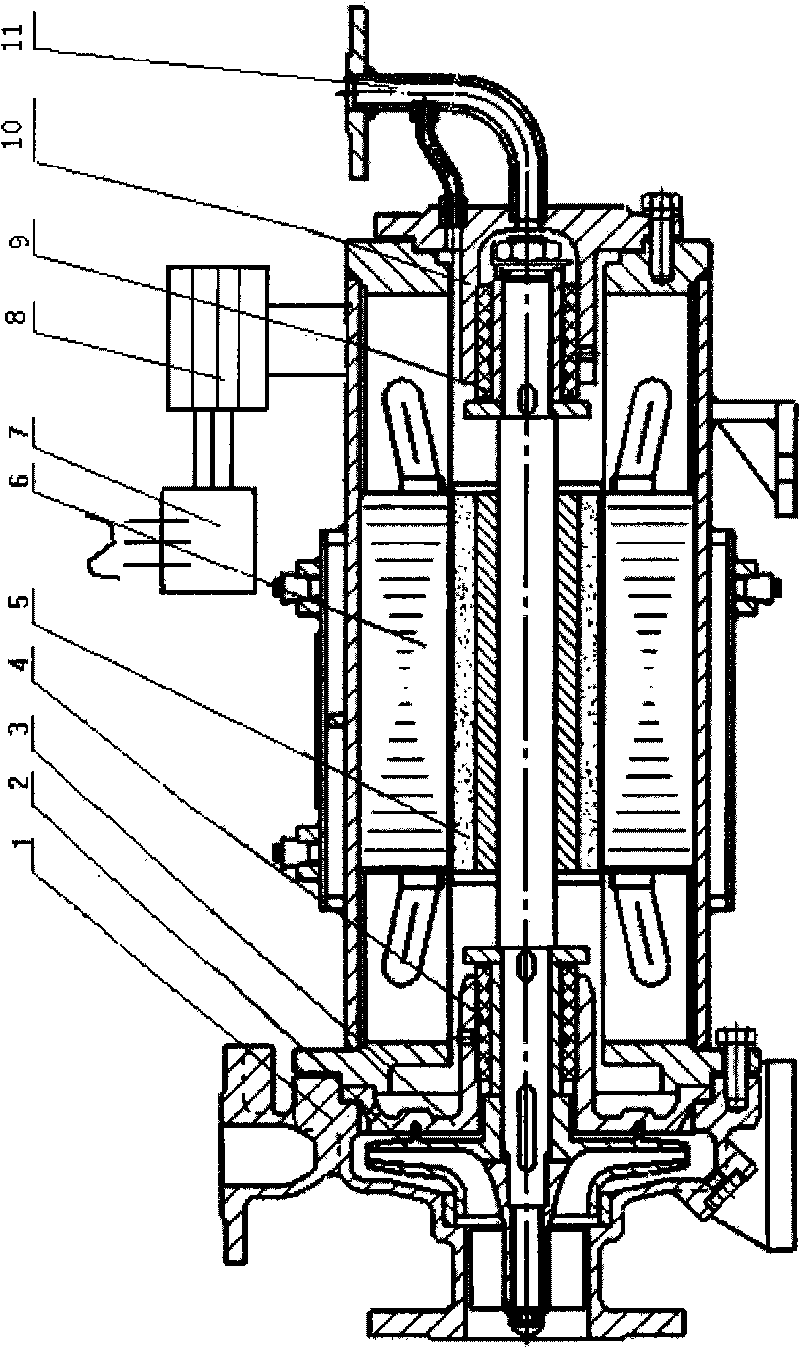

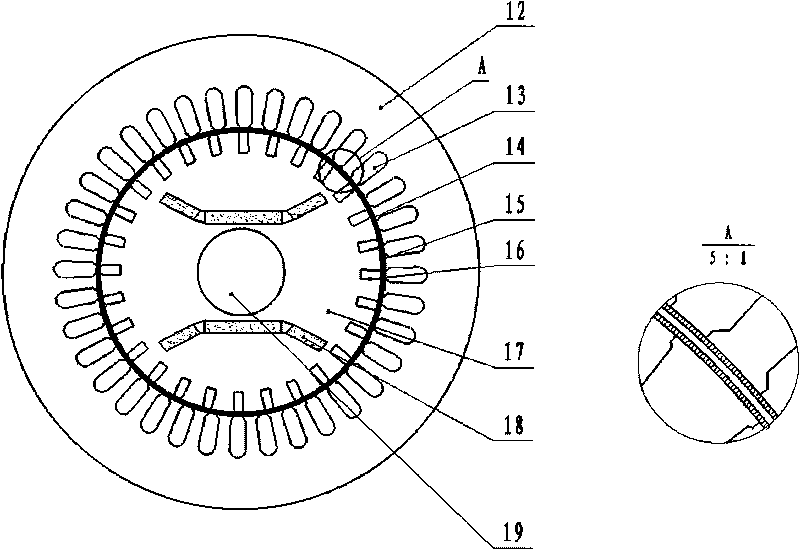

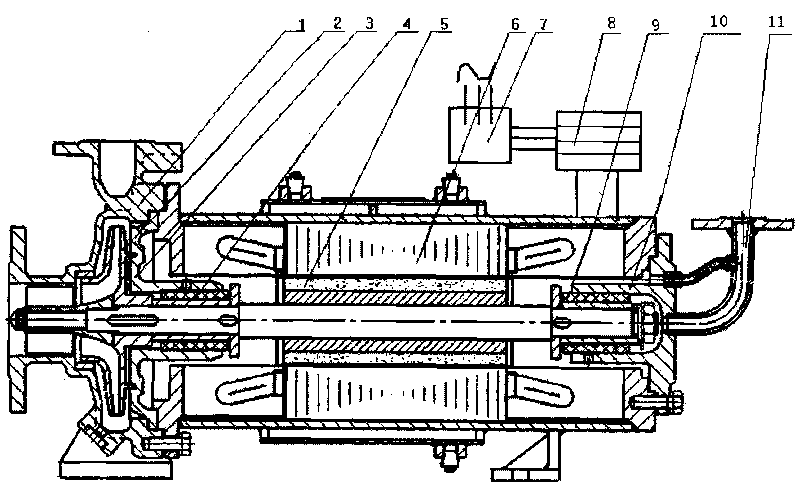

[0013] Frequency conversion high-speed permanent magnet shielded pump consists of pump body 1, impeller 2, rear end cover 3, leading bearing 4, permanent magnet rotor 5, stator 6, frequency converter 7, junction box 8, rear guide bearing 9, and rear cover plate 10 , circulation pipe 11. It is characterized in that a rotor shielding sleeve 15 is installed on the outer ring of the permanent magnet rotor 5; a stator shielding sleeve 14 is installed on the outer ring of the stator 6. The shielding sleeve is made of non-magnetic materials with high strength, corrosion resistance, high resistivity, good thermal conductivity, and excellent welding performance, such as Inconel alloy, Hastelloy alloy, Monel Alloy, 1Cr18Ni9Ti, 0Cr18Ni12Mo2Ti or industrial titanium etc. A permanent magnet 18 is built in the rotor core 17, and the permanent magnet adopts

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap