Load support structure

A technology for supporting structure and load, applied in the direction of benches, chairs, stools, etc., can solve the problem of unable to form a healthy posture, a hunched posture, etc., and achieve the effect of easy return to an upright sitting position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

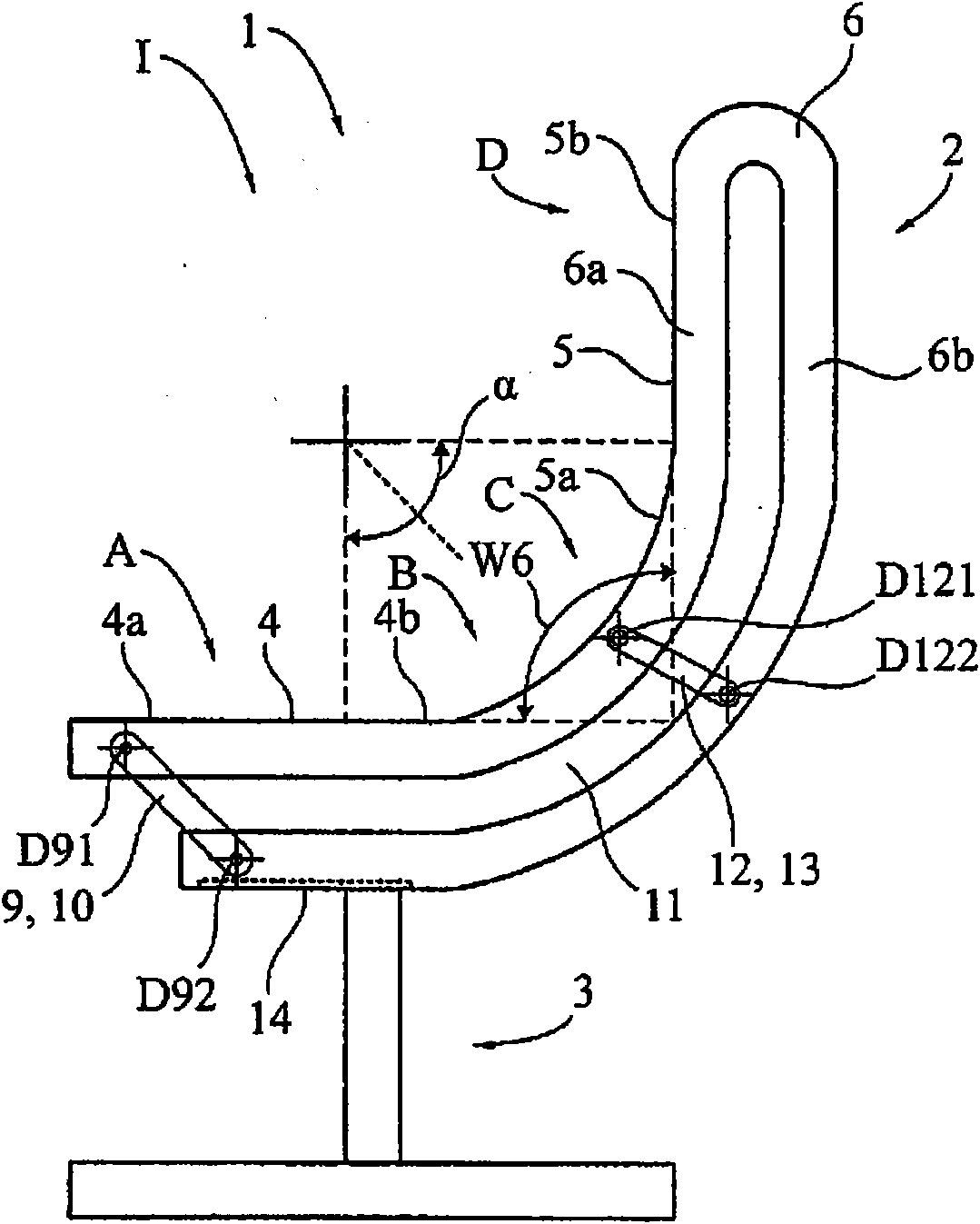

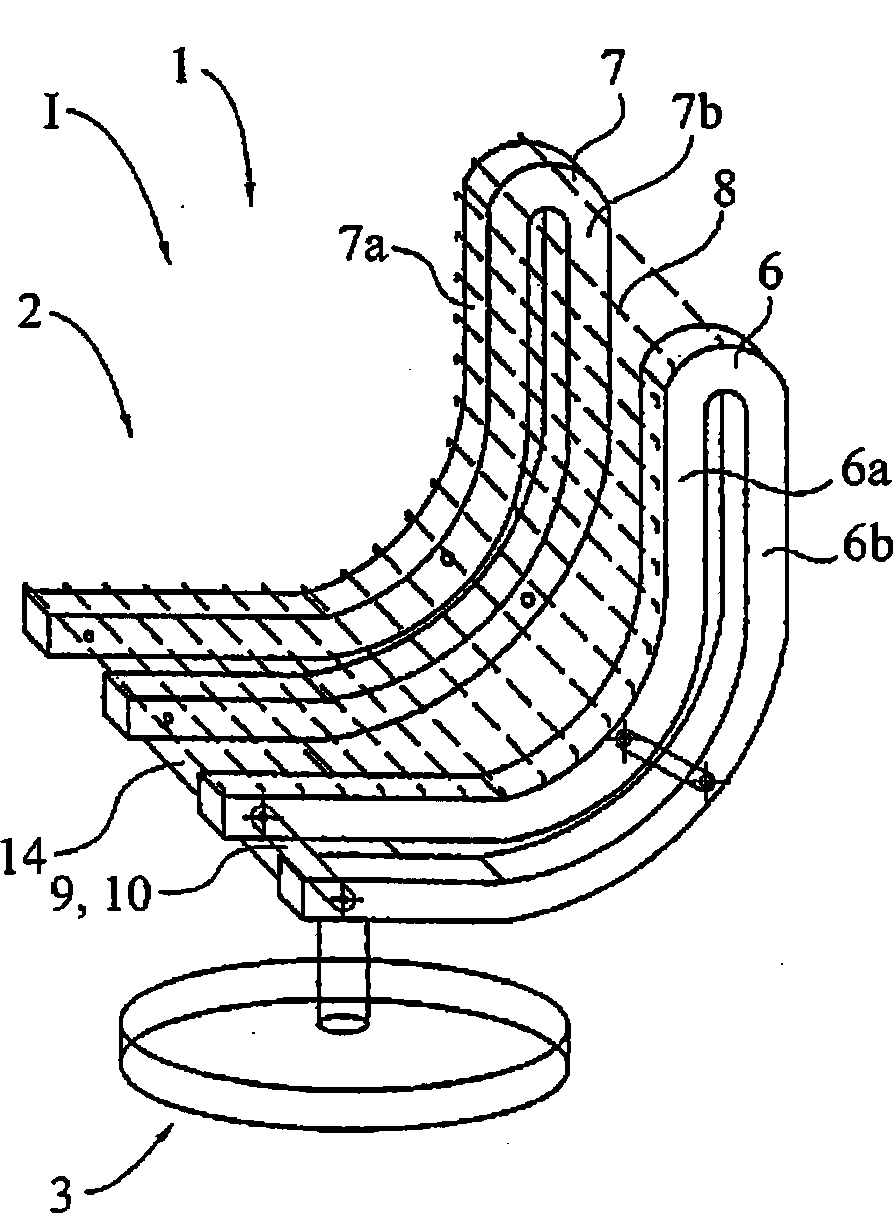

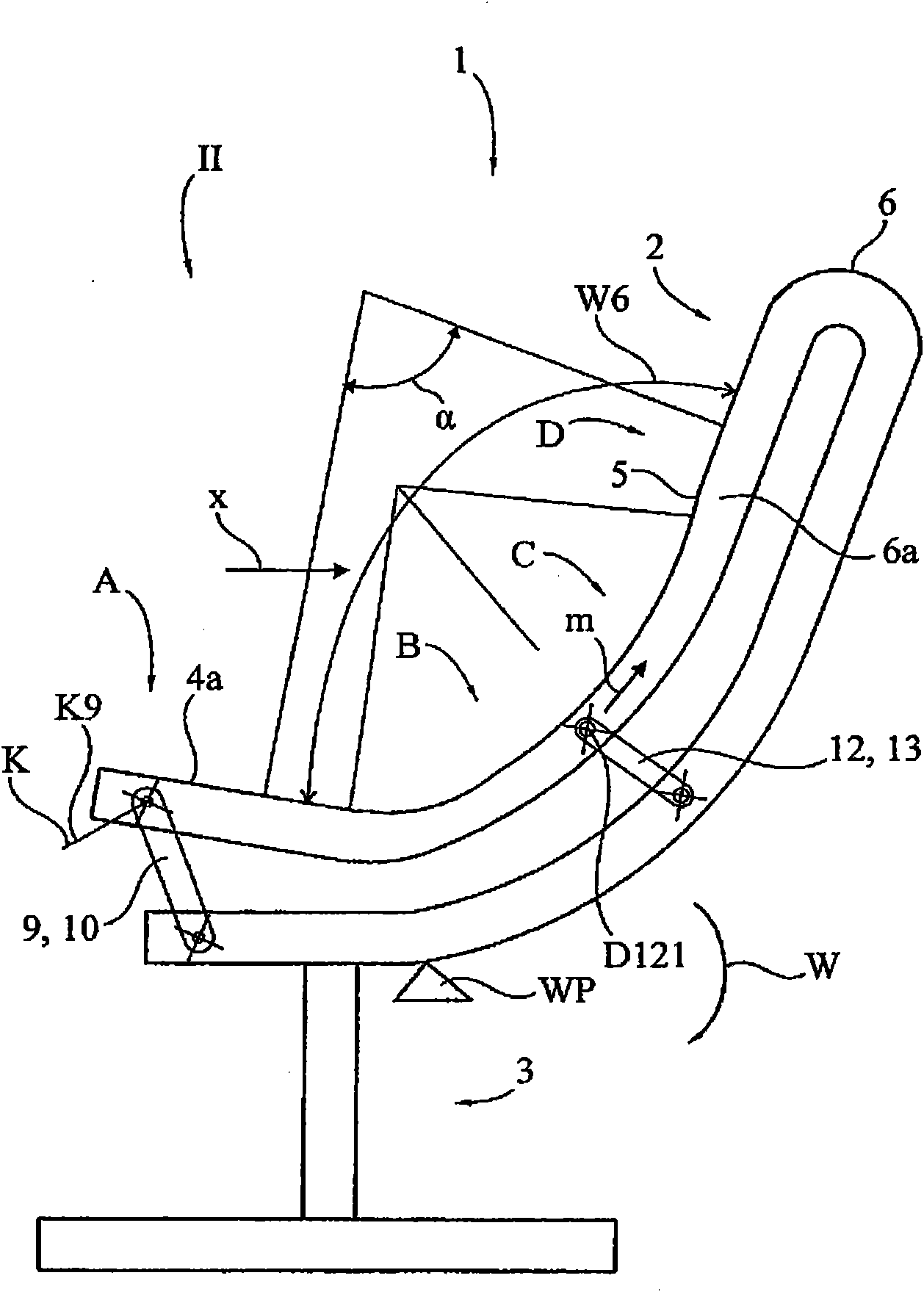

[0100] Figure 1a The socket 1 is illustrated in side view. The seat 1 comprises a seat element 2 and a lower frame 3 . The seat element 2 has a seat part 4 which is divided into a front seat part 4a and a rear seat part 4b. Furthermore, the seat element 2 also has a backrest part 5 which is divided into a lower backrest part 5a and an upper backrest part 5b. The seat element 2 comprises two support arms 6, 7 (or beam or carrier members), each support arm 6, 7 consisting of an upper support portion 6a or 7a (or first beam member) and a lower support portion 6b or 7b ( or second beam member) formed (see also Figure 1b ). only at Figure 1b The fabric 8 visible in is stretched between the two support arms 6, 7 and their upper supports 6a, 7a. Other body support members, such as shells or membranes (alone or in combination with fabric), may also bridge between the two support arms.

[0101] Figure 1b A simplified perspective view of the seat 1 shown in Figure 1 is shown. F

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap