Rail vehicle

A technology for motor vehicles and carriages, applied in the field of rail vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

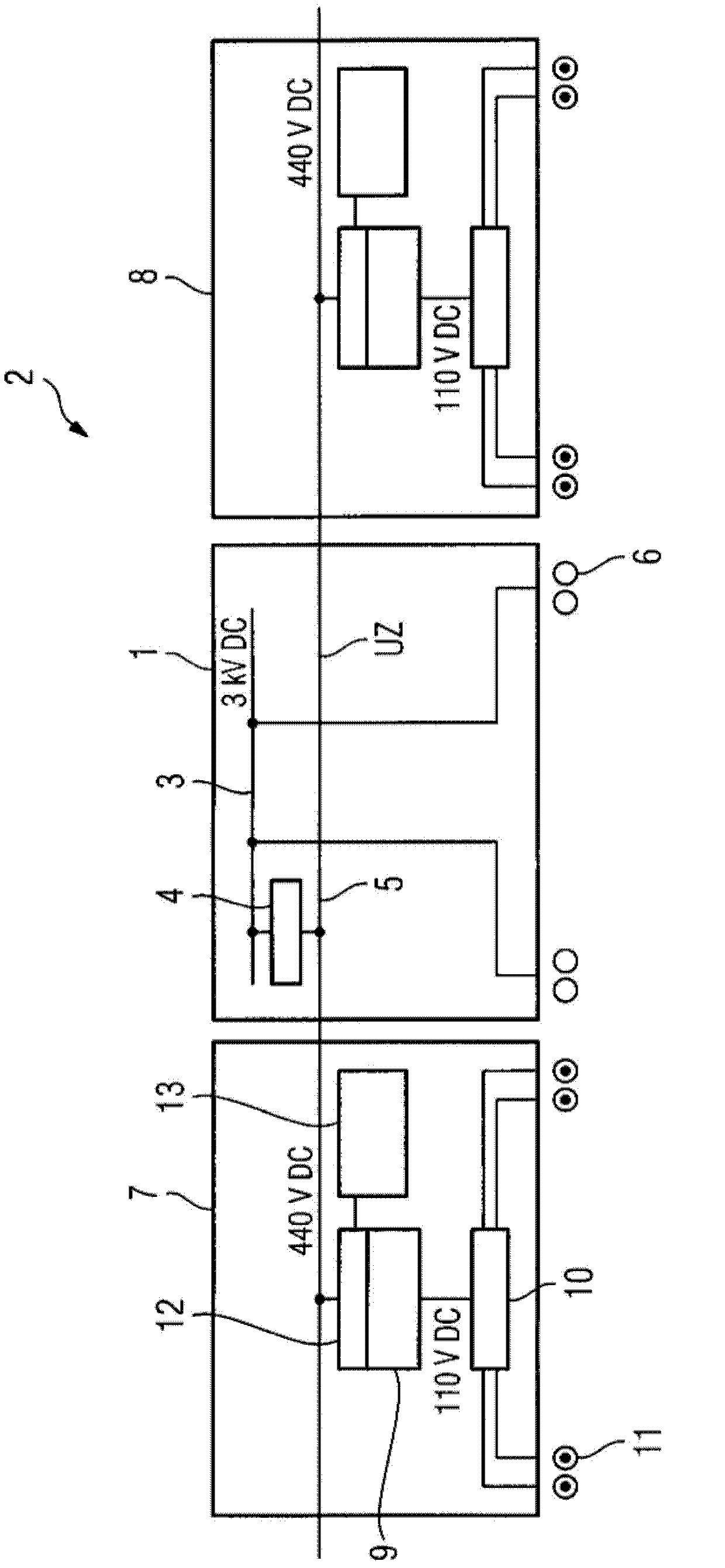

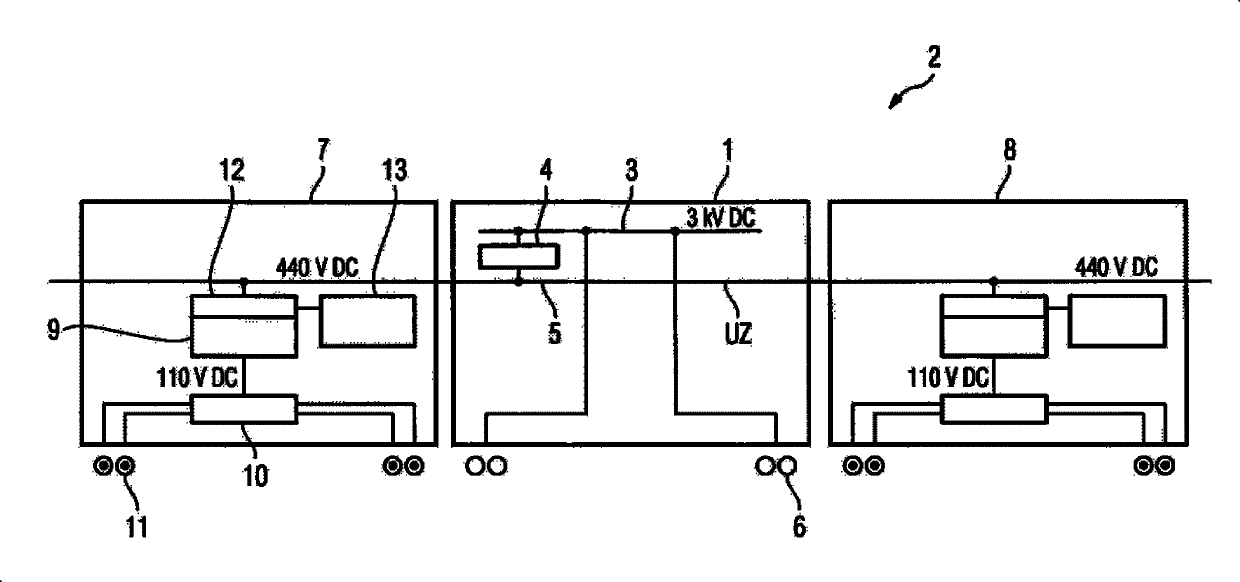

[0015] figure 1 The 1 marked in is the electric motor compartment of the rail vehicle 2. For the sake of clarity, only its traction intermediate circuit 3 and its converter 4 are shown for the motor car 1 . The voltage of the traction intermediate circuit, typically 3 kV DC, is converted by means of the converter 4 into a DC voltage Uz on the train bus 5 , which runs through all the cars of the rail vehicle 2 and is at a voltage level of 440 V DC. The motor car 1 is equipped with an electric motor, not shown, which is fed directly from the intermediate traction circuit. The small circles on the chassis of the motor car 1 shall represent the wheels or axles 6 driven by traction motors not shown.

[0016] In the illustrated rail vehicle 2 there is a first non-driven carriage 7 and a further non-driven carriage 8 on both sides of the electric motor carriage 1 . The two carriages 7 or 8 are here embodied identically in the relevant relation, so that the following description can r

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap