Method for maintaining butterfly valve sealing mechanism on line

A technology of sealing mechanism and butterfly valve, applied in the direction of lifting valve, valve device, mechanical equipment, etc., can solve the problems of inconvenient maintenance of butterfly valve, scrapping of butterfly valve, inconvenient maintenance, etc., and achieve the effect of shortening maintenance time, reducing loss and avoiding inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0016] The present invention will be further described below in conjunction with the drawings and embodiments:

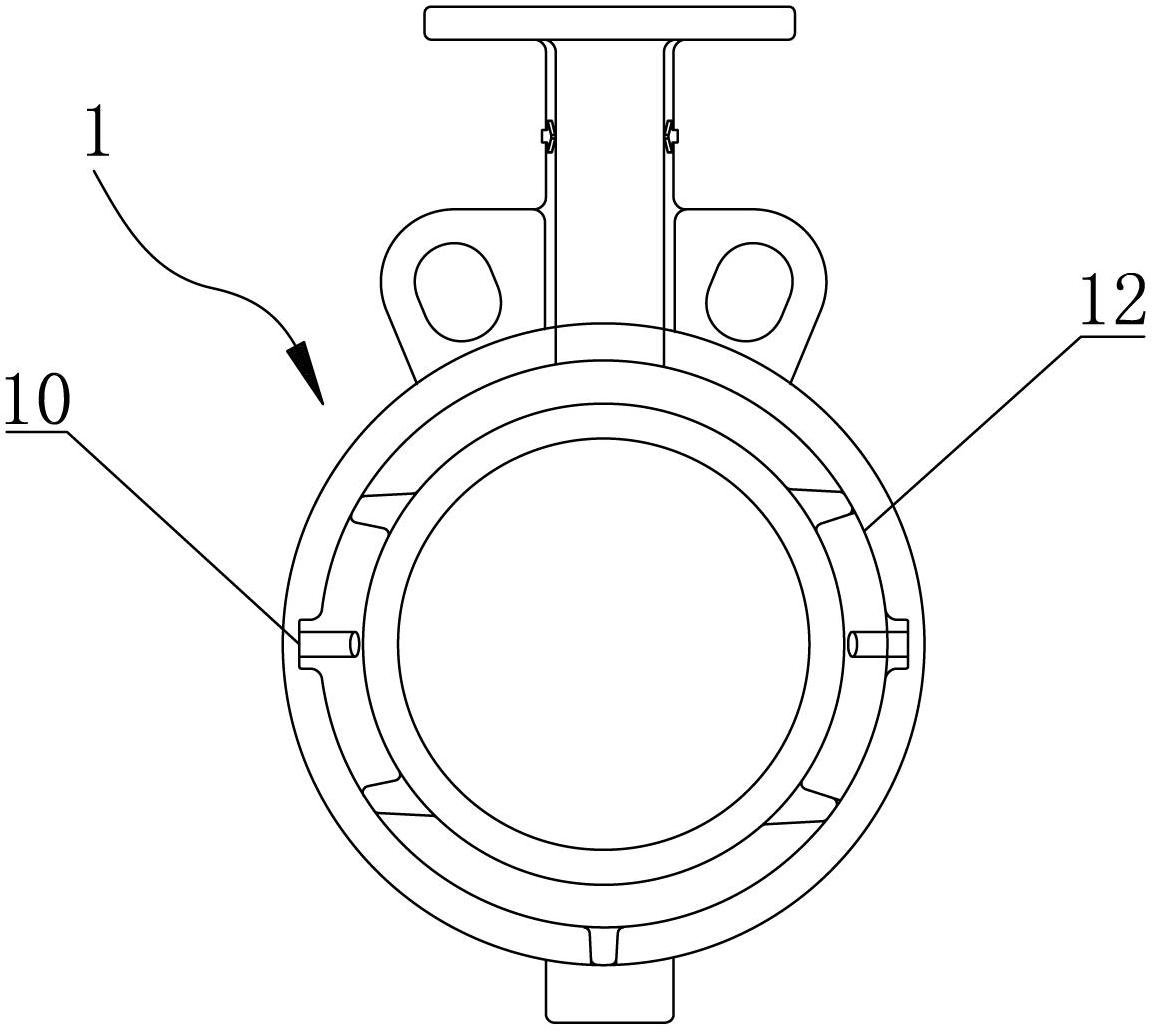

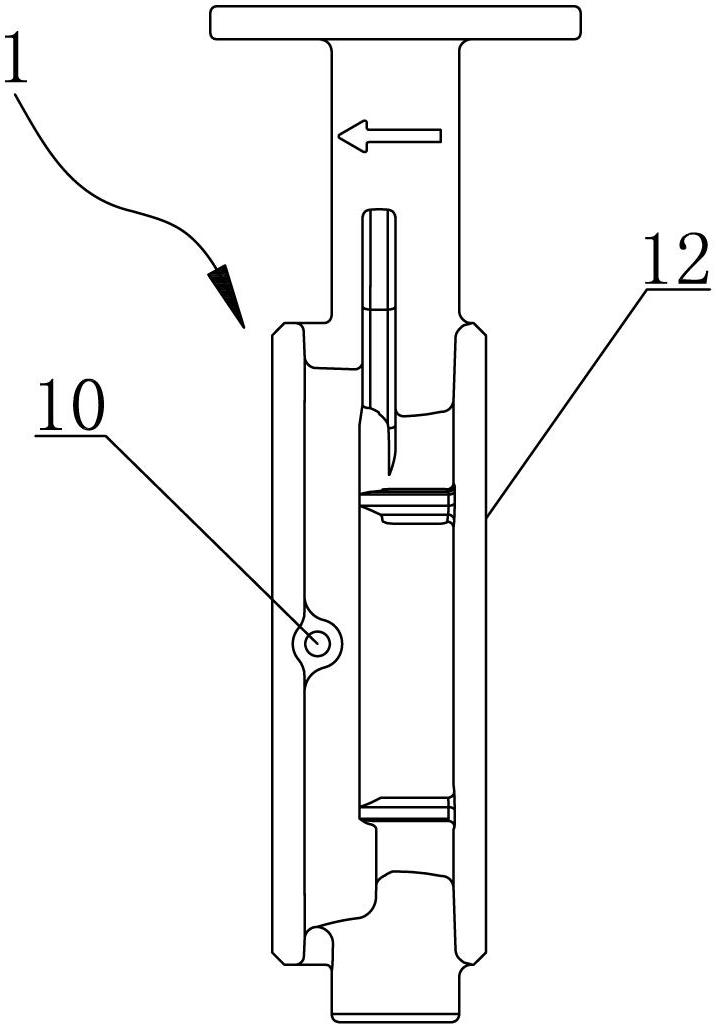

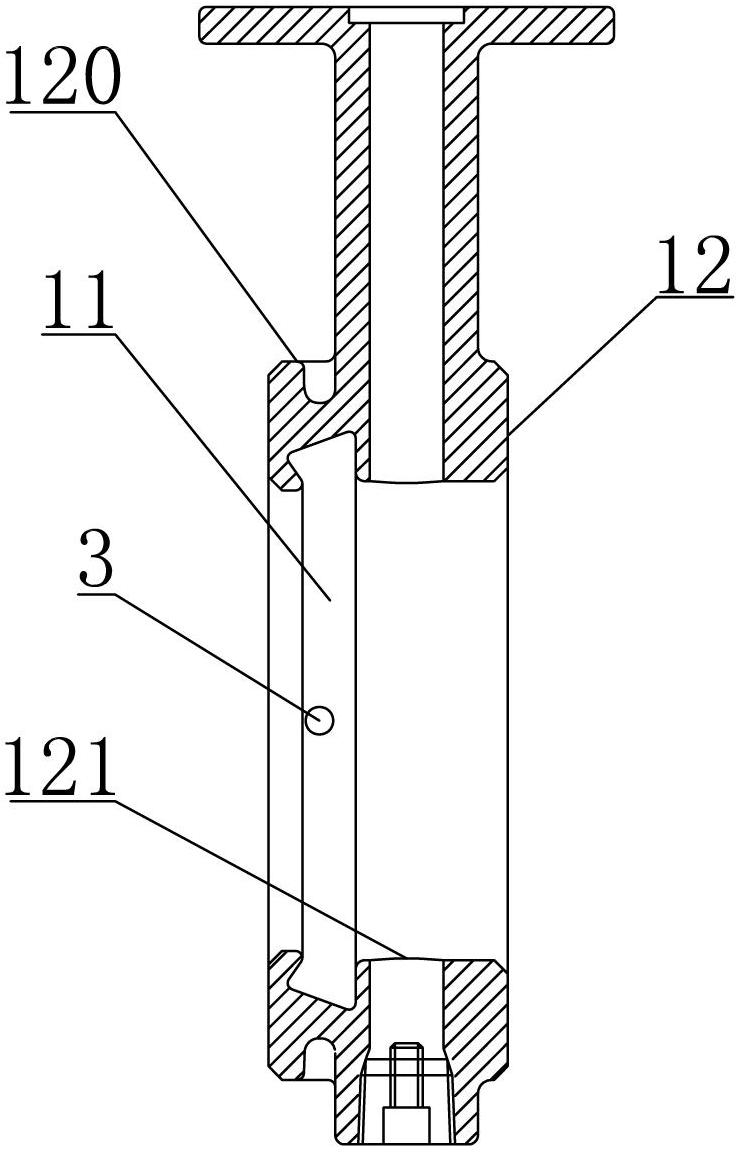

[0017] First introduce a butterfly valve, including a valve body 1, a butterfly plate and a valve stem. The valve body 1 is provided with a shaft hole 10, the valve stem passes through the shaft hole 10 and is fixedly connected to the butterfly plate, and the valve body 1 cooperates with the butterfly plate to form an opening. Closed pathway. Among them, the butterfly plate and the valve stem are not the key points of the design of the present invention, and their structures are not described here.

[0018] Such as Figure 1-3 As shown: a sealing mechanism is provided between the valve body 1 and the butterfly plate. The sealing mechanism includes a groove 11 opened on the valve body 1, and a sealing ring 2 arranged in the groove 11. In this embodiment, the valve body 1 There is an annular valve seat 12, the annular valve seat 12 has an outer peripheral surface 120, an i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap