Water discharging device for vacuum tank

A drainage device and vacuum tank technology, applied in the container discharge method, container filling method, gas/liquid distribution and storage, etc., can solve the problems of high failure rate, poor water absorption and drainage effect, high energy consumption, etc., and reach the failure rate Low, improve drainage effect, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

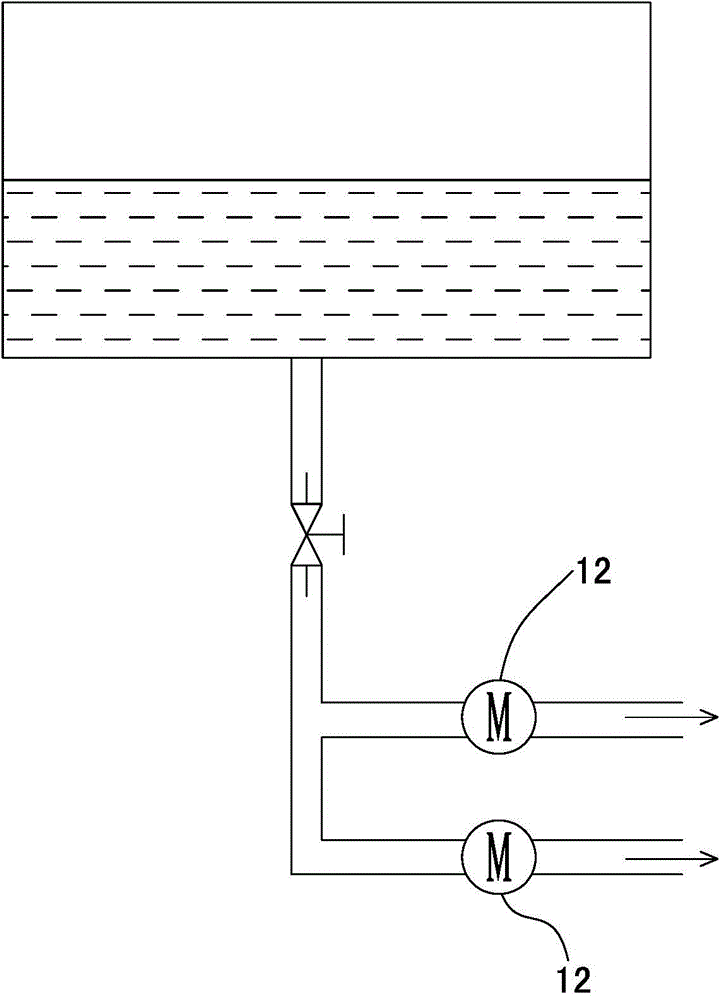

[0027] see figure 2 As shown, a drainage device for a vacuum tank includes a water storage tank 1, the top of the water storage tank is provided with a connecting pipe 2, a first ventilation pipe 3 and a second ventilation pipe 4, and the bottom of the water storage tank is provided with a drainage tube 5;

[0028] One end of the connecting pipe communicates with the bottom of the vacuum tank, so that the bottom of the vacuum tank communicates with the water storage tank; the connecting pipe is provided with a first valve 6;

[0029] One end of the second ventilation pipe communicates with the top of the vacuum tank, so that the top of the vacuum tank communicates with the water storage tank; the second ventilation pipe is provided with a second valve 7;

[0030] One end of the first ventilation pipe is arranged on the top of the water storage tank, and the other end communicates with compressed air or the atmosphere; the first ventilation pipe is provided with a pressure reduc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap