Paint gas oxidizing and washing tower device

A washing tower and paint gas technology, which is applied in the direction of combined devices, chemical instruments and methods, and dispersed particle separation, can solve problems such as reducing the life of activated carbon, blocking packing of washing towers, and increasing maintenance difficulties, so as to reduce peculiar smell and reduce device power Energy-efficient, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment

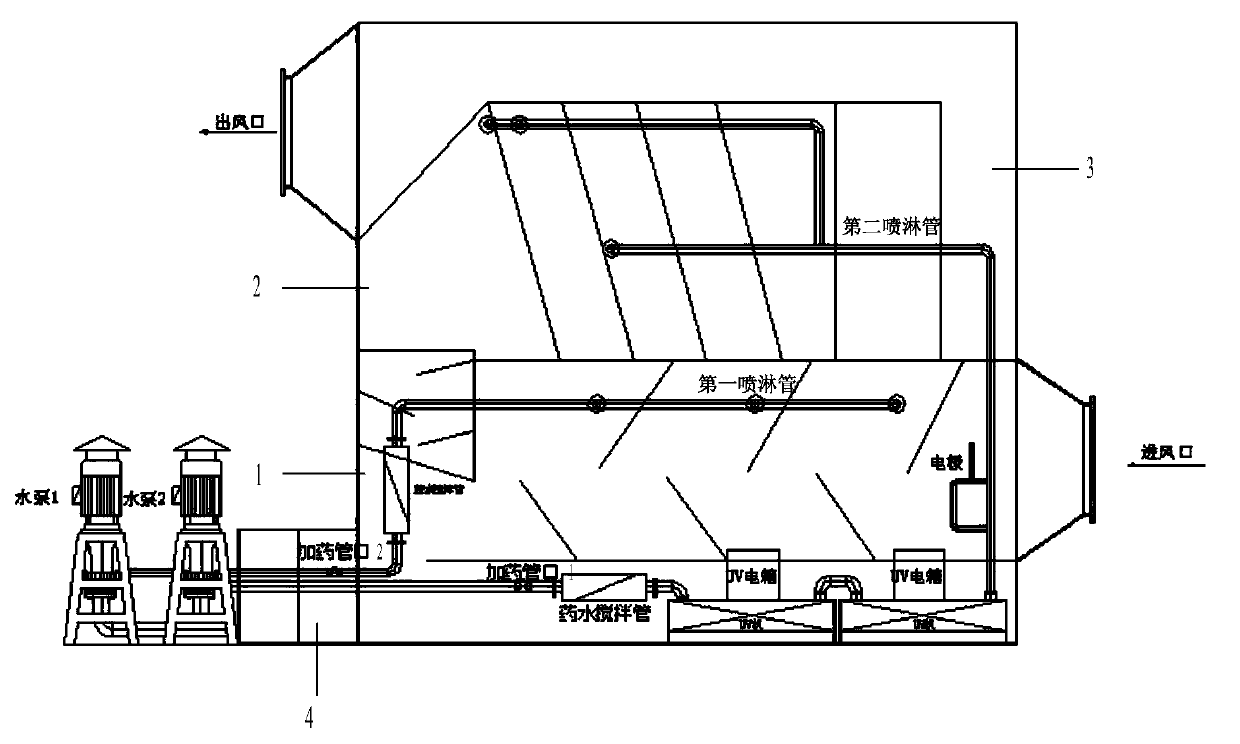

[0028] 1) Spraying exhaust gas enters the washing chamber 1 from the air inlet, is intercepted by multiple baffles, and under the action of the viscosity breaker in the spray liquid, the larger paint mist particles in the exhaust gas gather and settle in the paint gas oxidation scrubber device At the bottom, it enters the automatic slag discharge circulating pool 4, and the special viscosifier in the spray liquid sprayed by the first spray pipe is atomized to form layers of water films to capture fine particles (such as paint particles, toluene particles, Xylene particles), breaking the stickiness of the particles, agglomerating to form large particles to settle, separating solid and gas, and purifying the gas.

[0029] 2) The purified exhaust gas enters the oxidation chamber 2 from the communication hole in the middle, and before entering the oxidation chamber 2, the exhaust gas contacts with the water storage tank containing the oxidant at the communication point to carry out th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap