Automatic feeding system of rotary evaporator

A rotary evaporator, automatic feeding technology, applied in control/regulation systems, instruments, non-electric variable control, etc., can solve problems such as heavy workload, increase labor costs, etc., to achieve automation, save time and labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

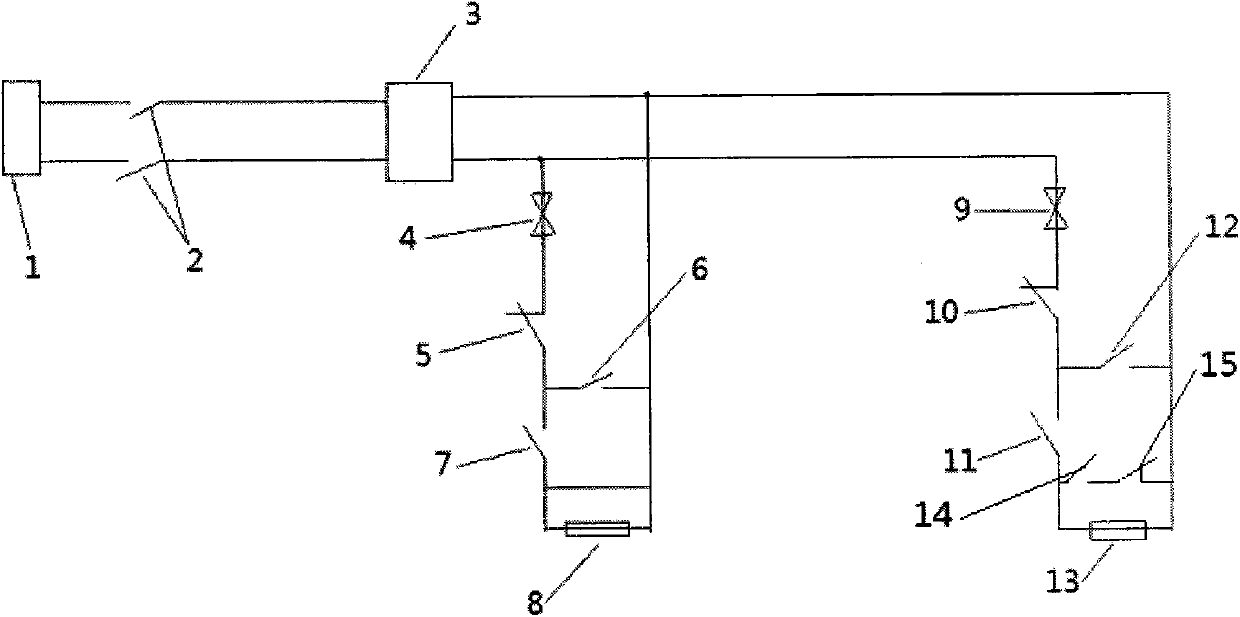

[0010] see figure 1 , figure 2 , an automatic feeding system for a rotary evaporator, this system includes a circuit breaker 2, a switching power supply 3, a first solenoid valve 4, a first liquid level switch 5, a second liquid level switch 6, a first normally open contact 7, a second A relay coil 8 , a second solenoid valve 9 , a third liquid level switch 10 , a fourth liquid level switch 11 , a second normally open contact 12 , a second relay coil 13 , a rotary switch 14 , and a normally closed contact 15 .

[0011] The circuit breaker 2 is connected to the AC power supply 1, and the circuit breaker 2 is also connected to the switching power supply 3. The first solenoid valve 4, the first liquid level switch 5, the first normally open contact 7, the first relay coil 8 and the switching power supply 3 The first circuit is formed in series, and the second liquid level switch 6 is connected in parallel with the first normally open contact 7 and the first relay coil 8 .

[0012

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap