Feeding and discharging integrated pressure casting clamp

An integrated, fixture technology, applied in the field of fixtures, can solve problems such as thermal deformation of molds, deviation of mold pin holes, difficulty in repeated positioning, etc., and achieve the effects of ensuring reliability, high integration, and small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0040] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

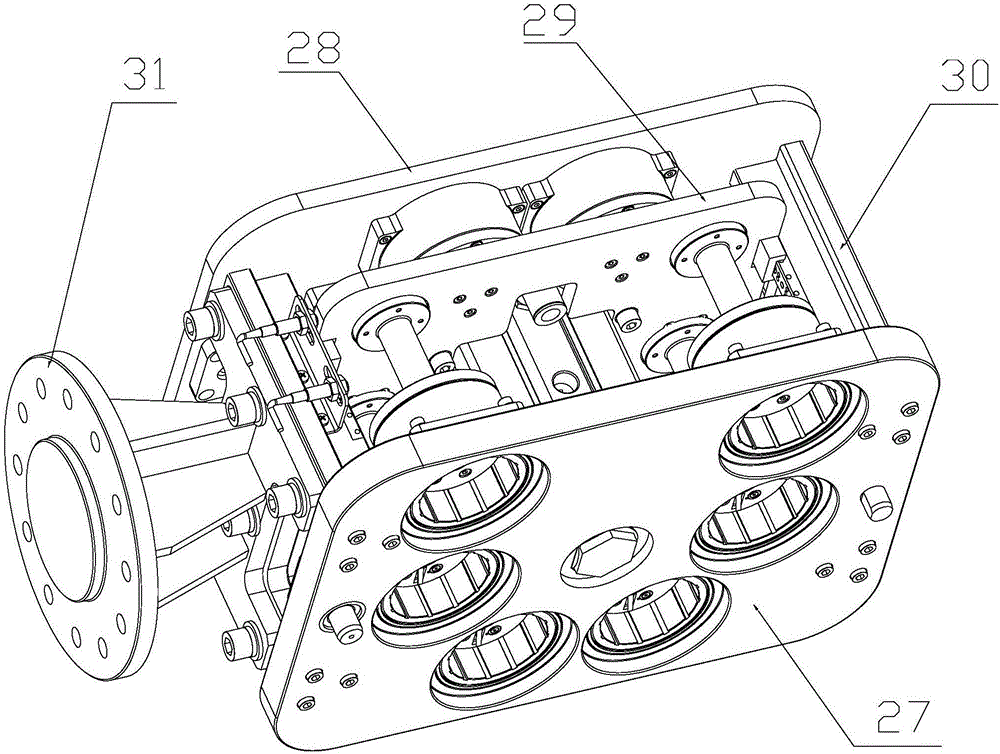

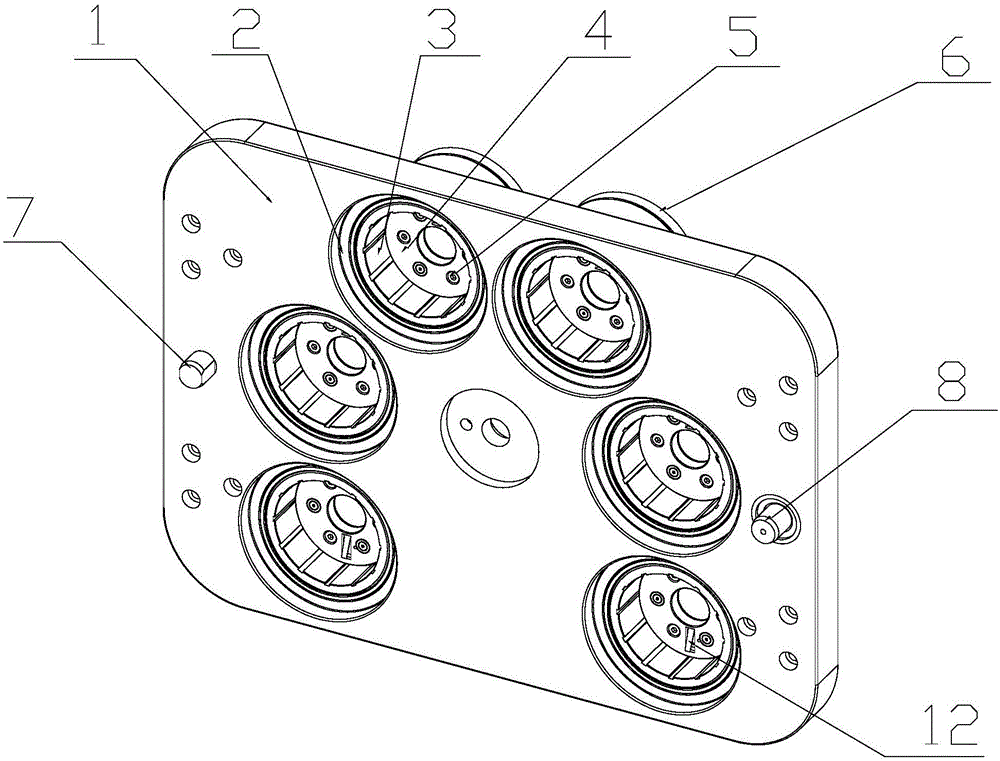

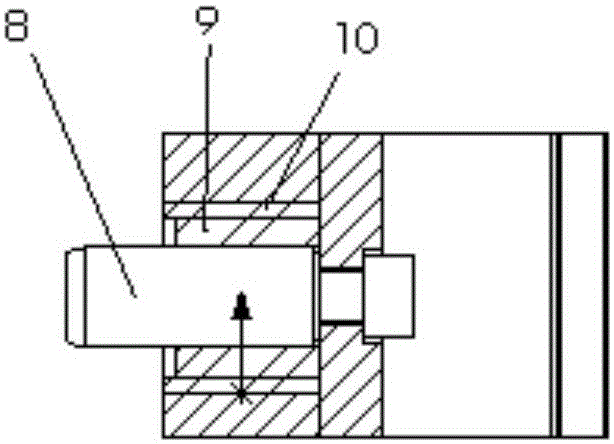

[0041] like figure 2 , image 3 , Figure 4 As shown, the feeding module includes: feeding module base 1, elastic high temperature resistant glue 2, feeding rotor sleeve 3, feeding backing plate 4, magnet 5, feeding end cover 6, chamfering pin 7, cylindrical pin 8, Pin sleeve 9, high temperature resistant inorganic glue 10, positioning pin pressing plate 11, micro switch 12 butterfly gasket 13 and so on.

[0042] The base body 1 of the blanking module mainly plays a supporting role, and the die steel has high hardness and good wear resistance; The high temperature resistant inorganic glue 10 is not flexible. After heating and solidification, it is close to steel. When used in combination, it can ensure that the clamp and the mold pin sleeve cooperat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap