Sediment sampler

A sampler and bottom mud technology, applied in the direction of sampling devices, etc., to achieve the effect of low sampling conditions, convenient assembly, and prevent sample leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 sediment sampler

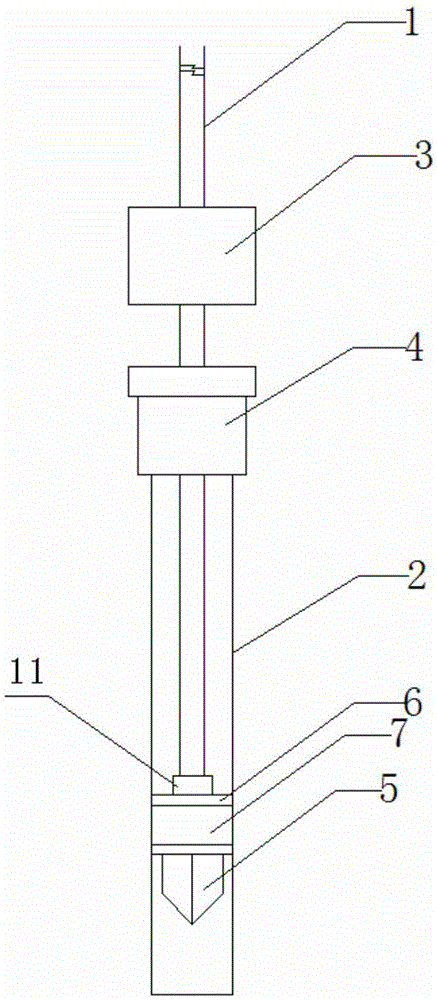

[0027] Such as figure 1 As shown, the sediment sampler is composed of a connecting rod 1, a sampling pipe 2, a gravity hammer 3, a fixed joint under force 4, a piston firmware 5, a piston gasket 6 and a rubber piston 7.

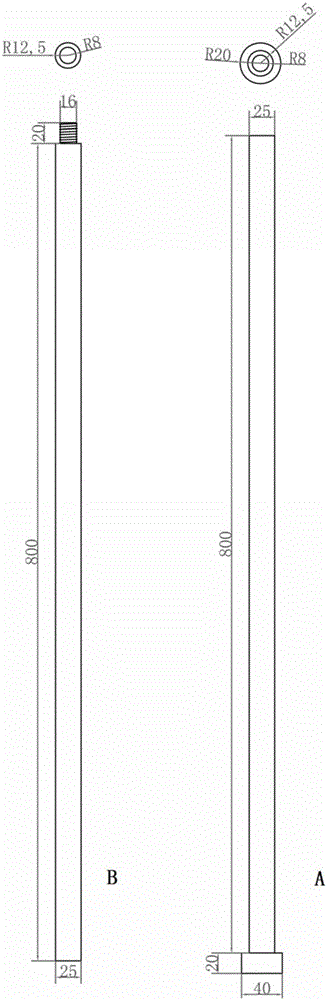

[0028] Such as figure 2 As shown, connecting rod 1 is processed by sampling metal materials. The length is determined according to the sampling depth. It can be directly borrowed from the drilling rod in the survey work. Its main function is to connect the gravity hammer, the fixed joint under force, the piston firmware, the piston gasket, and the rubber piston. , Water sampling at different depths can be realized by connecting and lengthening. The length of each connecting rod is 50cm-100cm, and the number and size of connections are determined according to the depth of the water body. figure 2 A is a single connecting rod, figure 2 B is an extension rod.

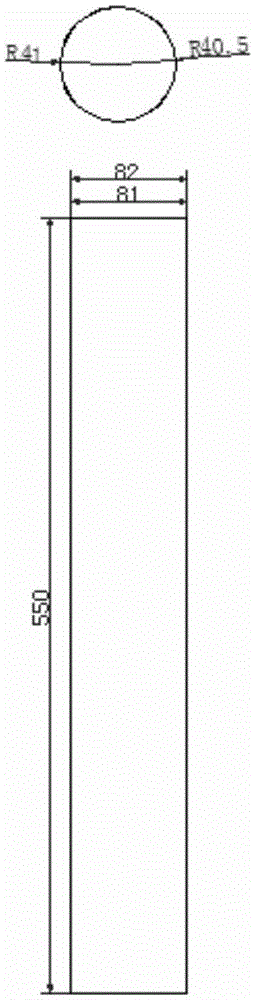

[0029] Such as Figure 5 As shown, the stressed fixed joi

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap