Complete vehicle road test room vehicle travelling channel device

A technology for vehicle driving and whole vehicle road, which is applied in the direction of measuring device, vehicle testing, machine/structural component testing, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

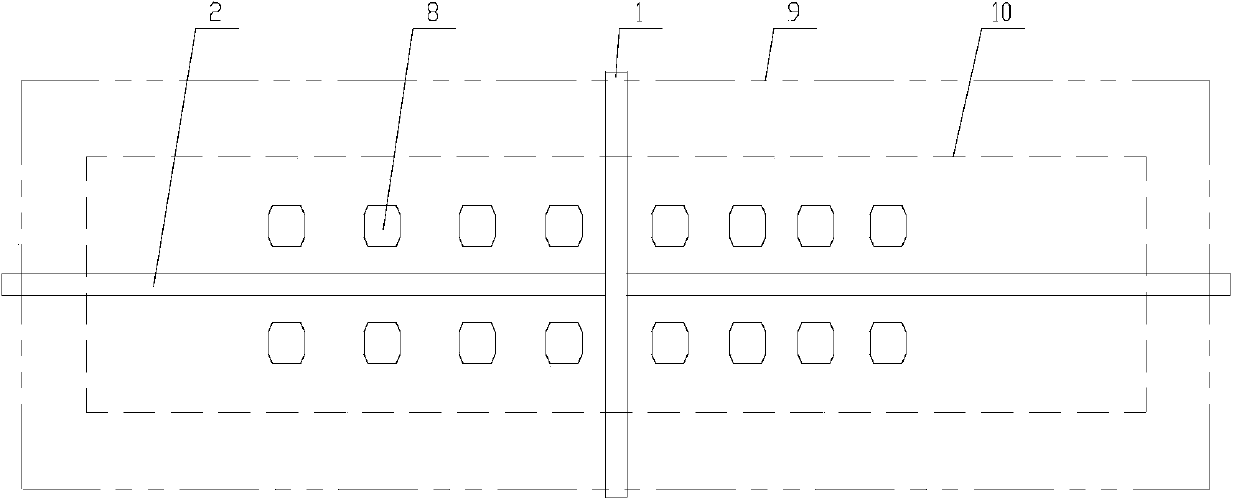

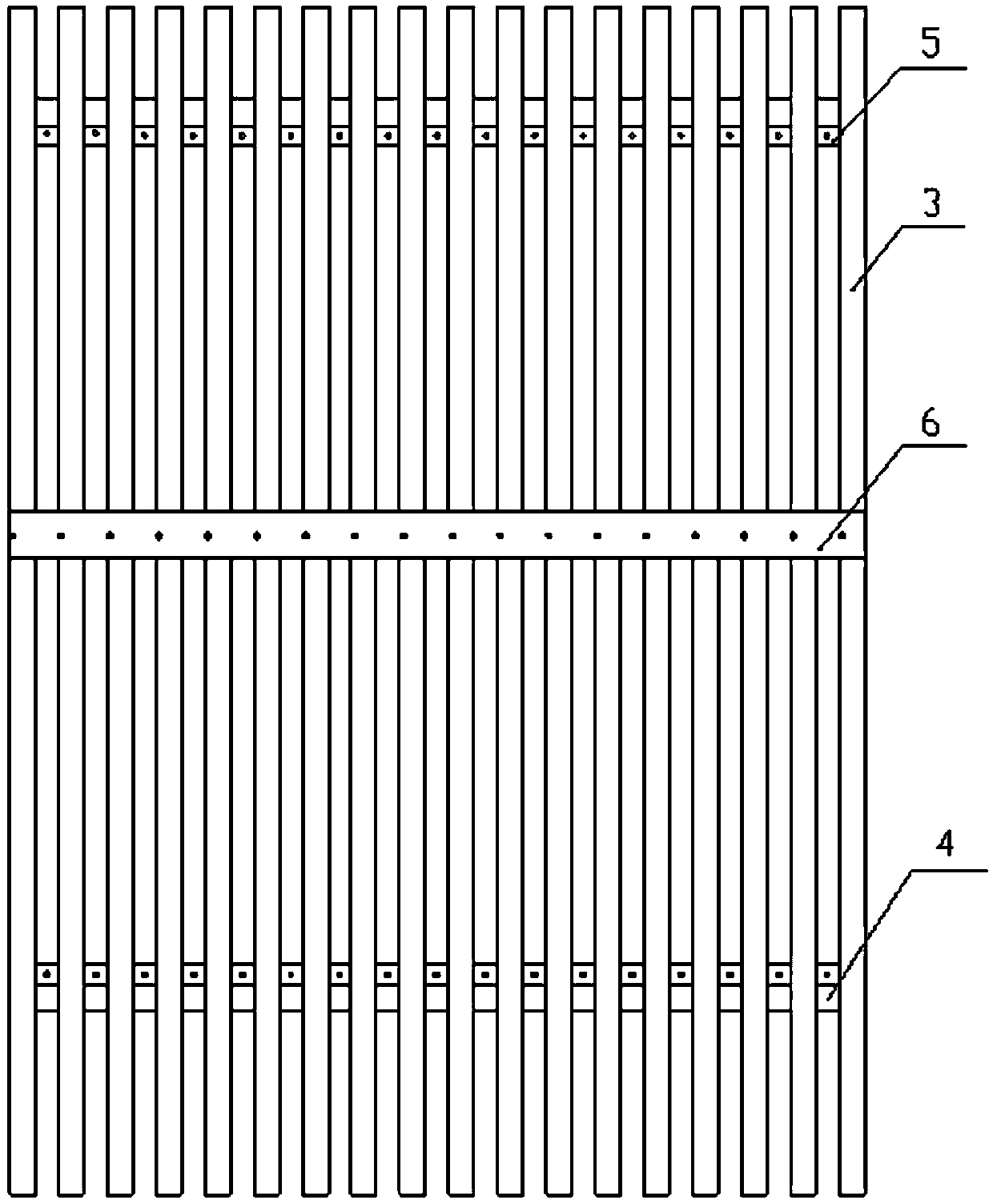

[0023] This embodiment provides a vehicle running channel device for a vehicle road test room, the structure of which is as follows: Figure 1 to Figure 3 As shown, it includes a beam 1 , two longitudinal beams 2 , a plurality of platform modules, an auxiliary cover plate 7 and an actuator 8 .

[0024] The two ends of the crossbeam 1 are directly fixedly installed in the bearing areas on both sides of the pit wall 9. One end of the longitudinal beam 2 is supported by the crossbeam 1, and the other end is supported by the pit wall. The beam 1 and the longitudinal beam 2 can adopt box girder, I-shaped beam or other cross-section types, and are the main load-bearing structure of the device. One end of the platform module is installed on the longitudinal beam 2, and the other end is installed on the pit wall 9, and each platform module is closely a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap