Strip mounting equipment

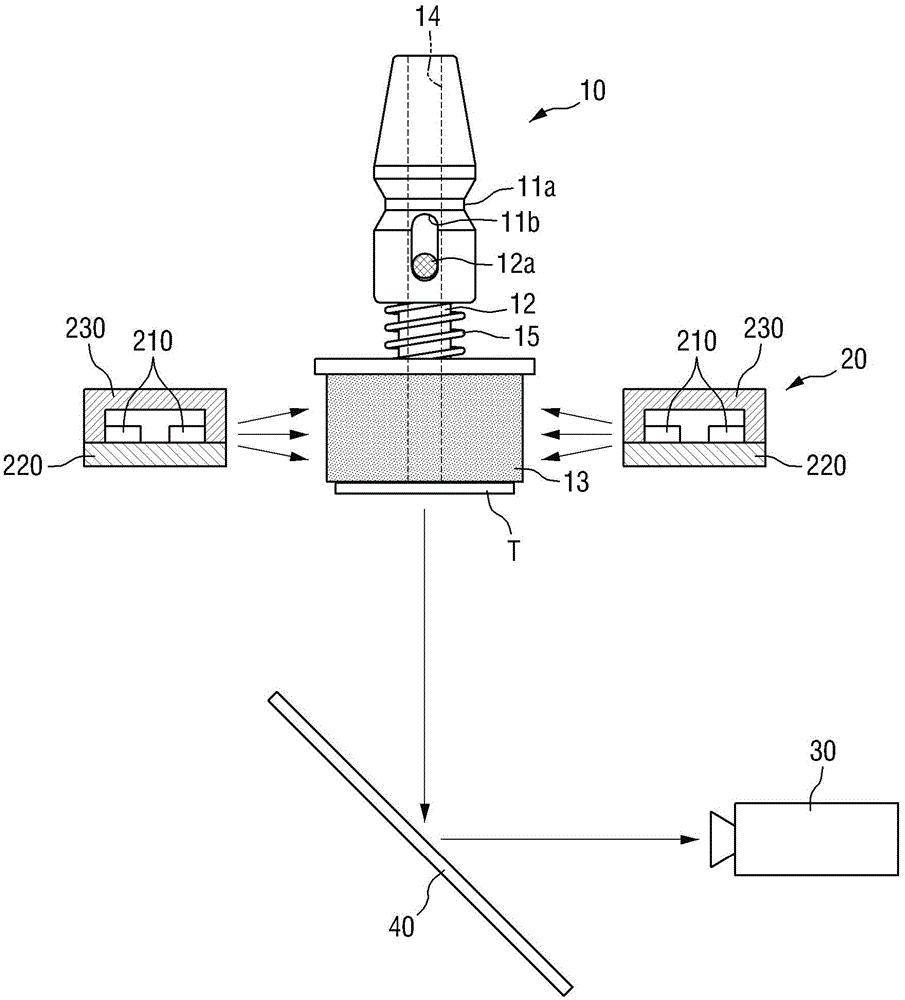

A tape and mounting technology, applied in the field of tape mounting equipment, can solve the problems that the tape cannot be clearly expressed, and the structure of the component placement machine cannot be applied, so as to achieve the effect of improving light uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

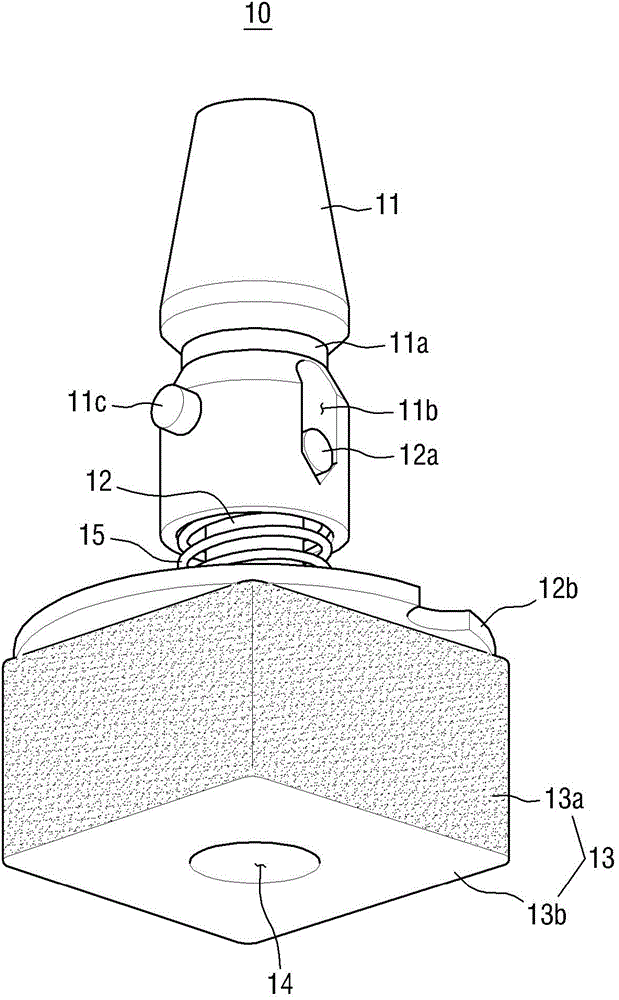

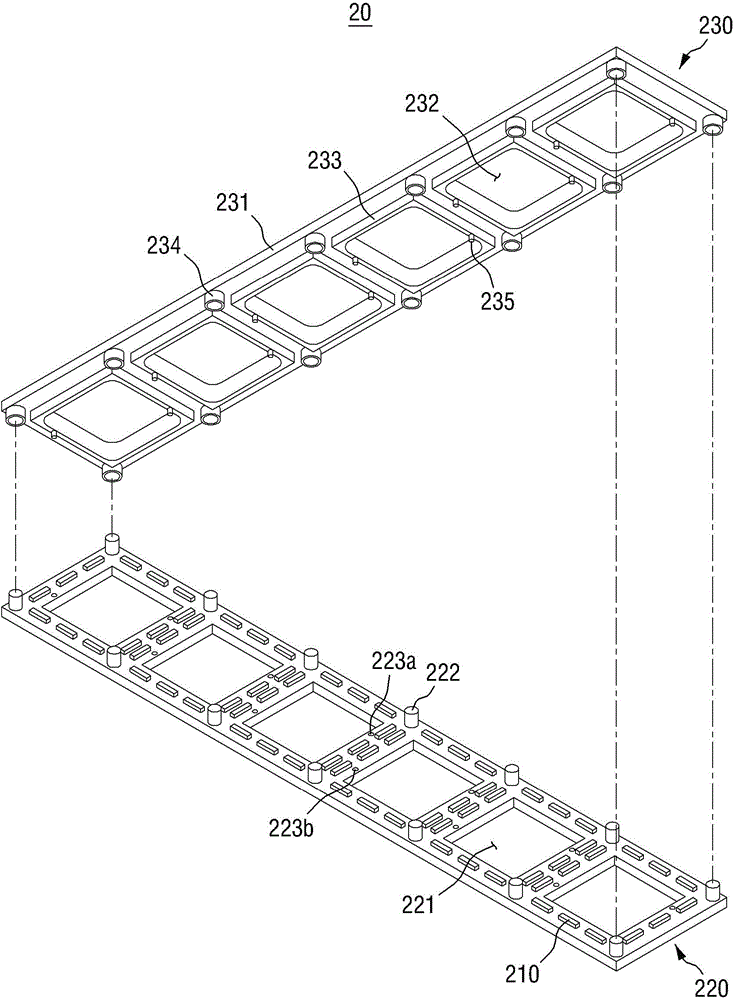

[0043] The advantages, features, and methods used to achieve the objectives of the present invention will be understood with reference to the embodiments described in detail in conjunction with the drawings. However, the present invention is not limited to the embodiments disclosed below. It can be implemented in different forms. The embodiments are only for fully disclosing the present invention and fully telling the scope of the present invention to those in the technical field to which the present invention belongs. Provided by persons with ordinary knowledge, the present invention is only defined by the claims. Throughout the entire specification, the same reference numerals denote the same constituent elements.

[0044] In addition, the aforementioned embodiments will be explained with reference to cross-sectional views and / or schematic diagrams which are idealized example drawings of the present invention. Therefore, the form of the example diagram may be changed according

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap