Multi-margin multi-power channel permanent magnetism generator

A permanent magnet generator, multi-power technology, applied in multi-output synchronous motors, synchronous motors with static armatures and rotating magnets, and the shape/style/structure of winding conductors, etc., can solve the problem of high cost, large space, problems such as large weight, to achieve the effect of ensuring output capacity, improving power density, and meeting multi-power and multi-margin requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

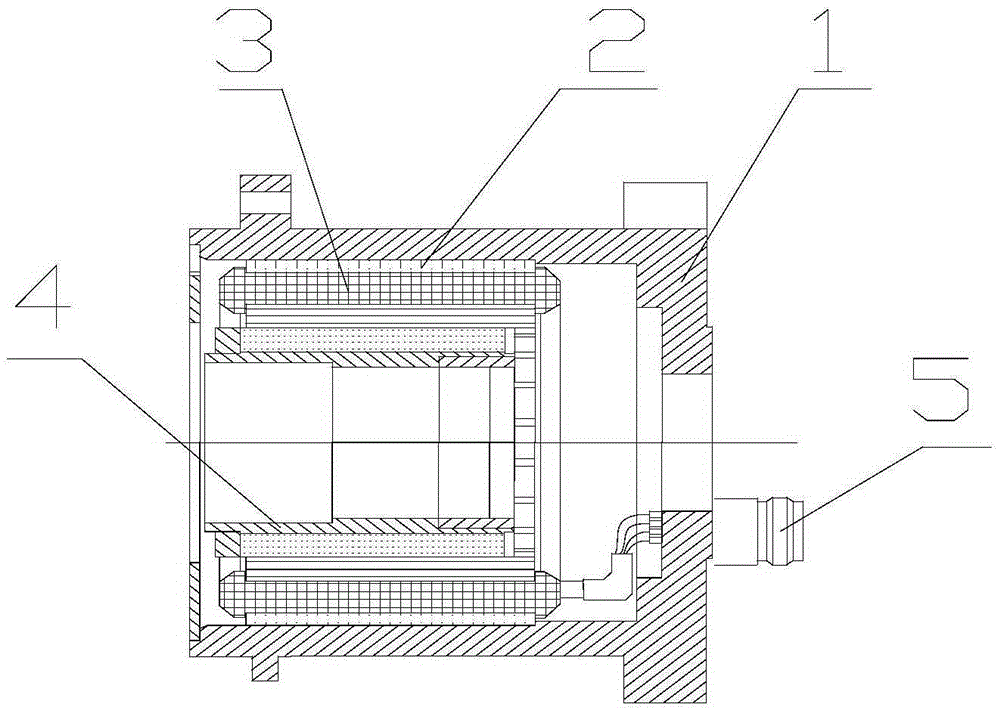

[0011] Example

[0012] An aircraft power supply requires power supply for loads with power of 130W and 50W, and the power of 130W has three margins. The specific structure of the permanent magnet motor is:

[0013] The permanent magnet generator includes a stator iron core, a stator winding, a rotor with magnetic poles, and a housing. The stator iron core is installed on the housing and is provided with stator windings. The rotor with magnetic poles is arranged in the stator iron core; on the stator There are uniformly distributed slots, the number of slots Z=3*(n+2m), where Z is the number of slots, n is the number of channels that can meet the output voltage by one winding, and m is the number of channels that need corresponding two windings. The number of channels that can meet the output voltage; after calculation, one winding can meet the power of 50W, but two sets of power are required to meet the power of 130W, so n is 1, m is 3, then Z, that is, the number of slots is 21; al

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap