Temperature sensor fault diagnosis method and system

A temperature sensor and fault diagnosis technology, applied in thermometers, thermometer testing/calibration, instruments, etc., can solve problems such as increasing hardware volume and cost, improve effective utilization, reduce redundancy, and avoid misjudgment of battery status. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Please refer to Figure 1-5 , Embodiment 1 of the present invention is:

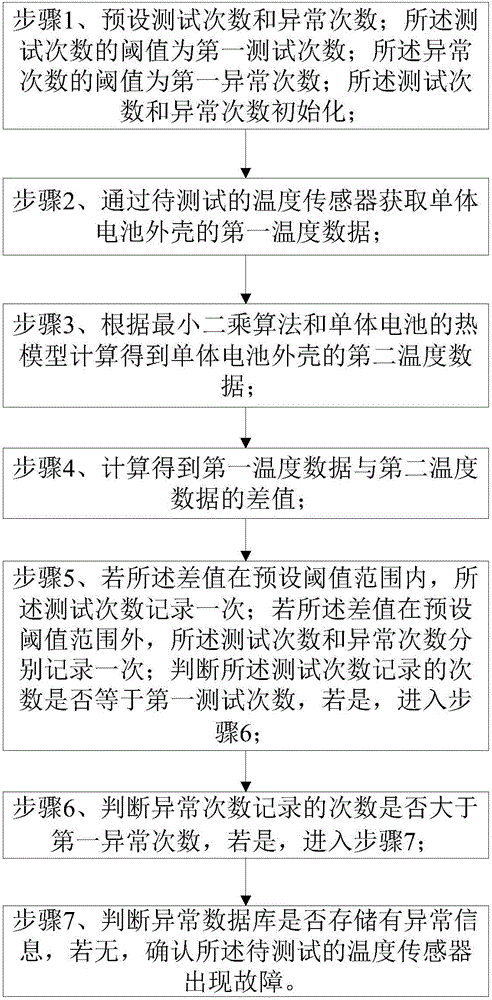

[0084] A kind of fault diagnosis method of temperature sensor provided by the present invention comprises:

[0085] Step 1, preset the number of tests and the number of abnormalities; the threshold of the number of tests is the first number of tests; the threshold of the number of abnormalities is the first number of abnormalities; the number of tests and the number of abnormalities are initialized, specifically: the number of tests K y and the number of abnormalities K x The recorded number of times is cleared (K y = 0,K x =0). The first number of tests is set to 50 times, and the first number of abnormalities is set to 5 times.

[0086] Step 2. Obtain the first temperature data T of the single battery casing through the temperature sensor to be tested s ;

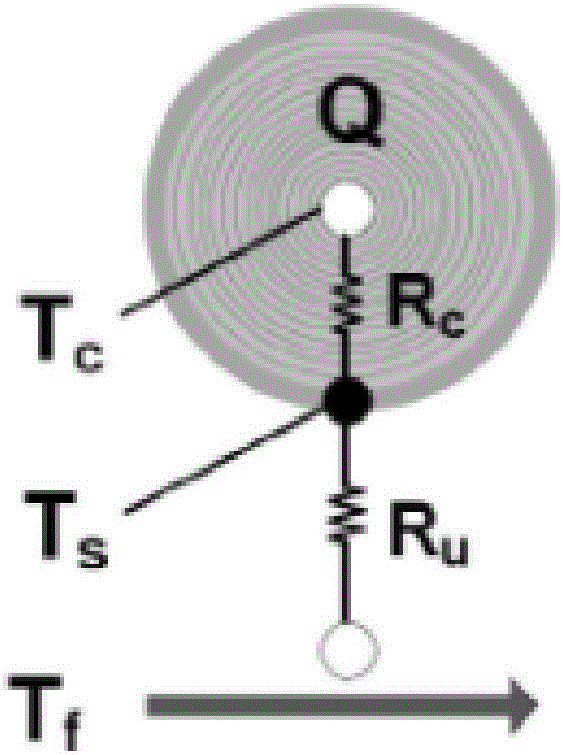

[0087] Step 3. Calculate the shell temperature of the single battery according to the least squares algorithm and the thermal model of

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap