Electric self-locking type contactor

A self-locking, contactor technology, applied in the direction of relays, electrical components, electromagnetic relays, etc., can solve the problems of wasting power resources, failure of power failure, etc., and achieve the effect of unique structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

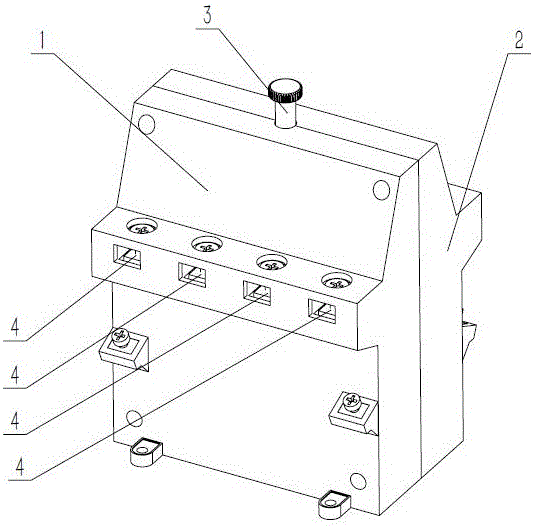

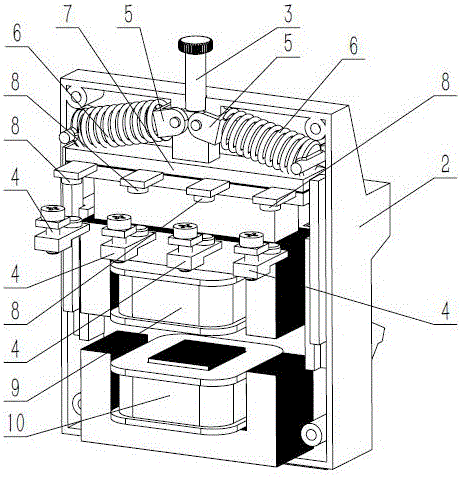

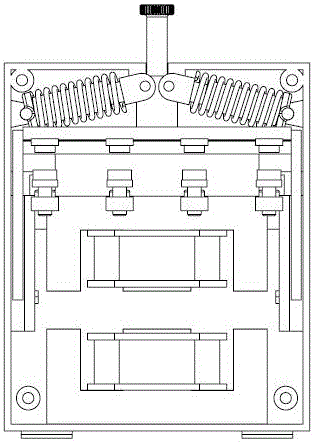

[0013] Such as figure 1 , figure 2 , Figure 5 As shown, an electrical self-locking contactor includes a housing, a manual handle 3, two self-locking levers 5, two self-locking springs 6, a sliding connecting plate 7, eight terminals 4, and a sliding electromagnet 9 And fixed electromagnet 10, it is characterized in that: described casing comprises front casing 1 and rear casing 2, and front casing 1 and rear casing 2 are mutually symmetrically connected by screw; Described fixed electromagnet 10 is installed on The lower position inside the housing; the manual handle 3 slides up and down and is installed at the upper position inside the housing. The other ends of 5 are respectively hingedly mounted on the lower pa

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap