Rearview mirror installation structure on vehicle door

A technology for mounting structure and rearview mirror, applied in vehicle parts, transportation and packaging, optical observation devices, etc., can solve problems such as wind noise, rearview mirror jitter, etc., to prevent rust, ensure strength, and prevent non-fitting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

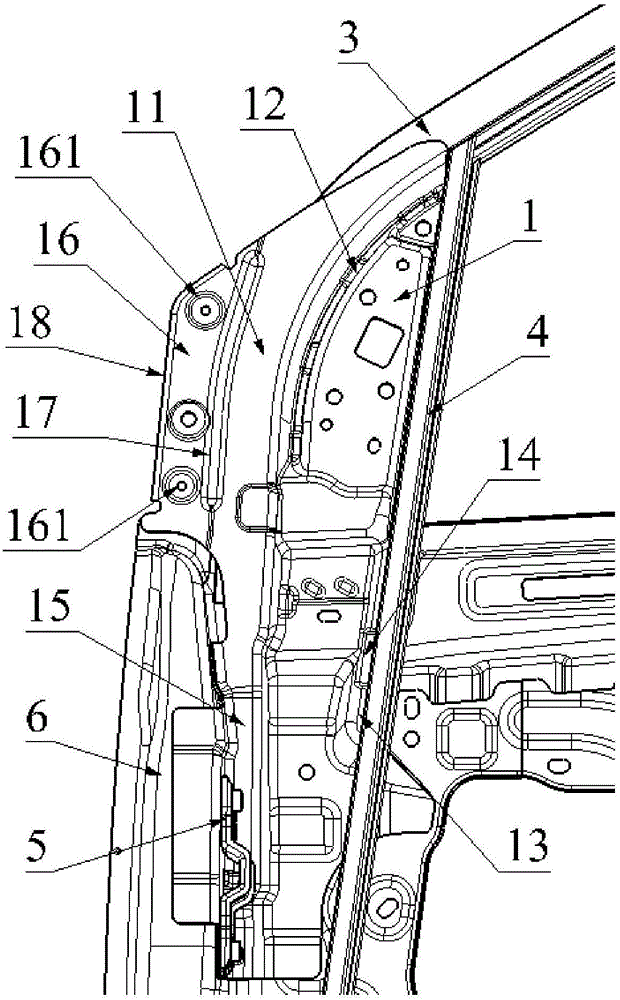

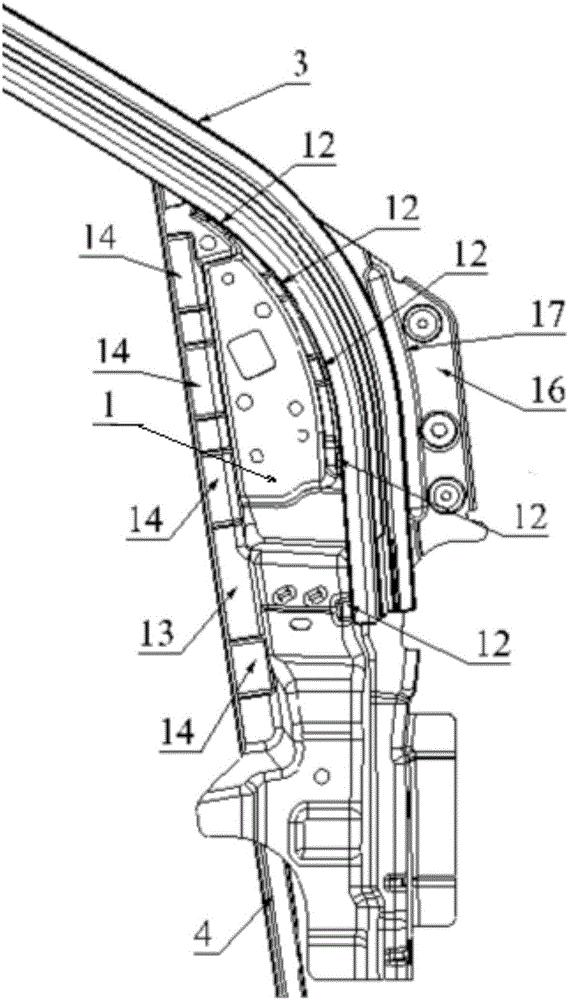

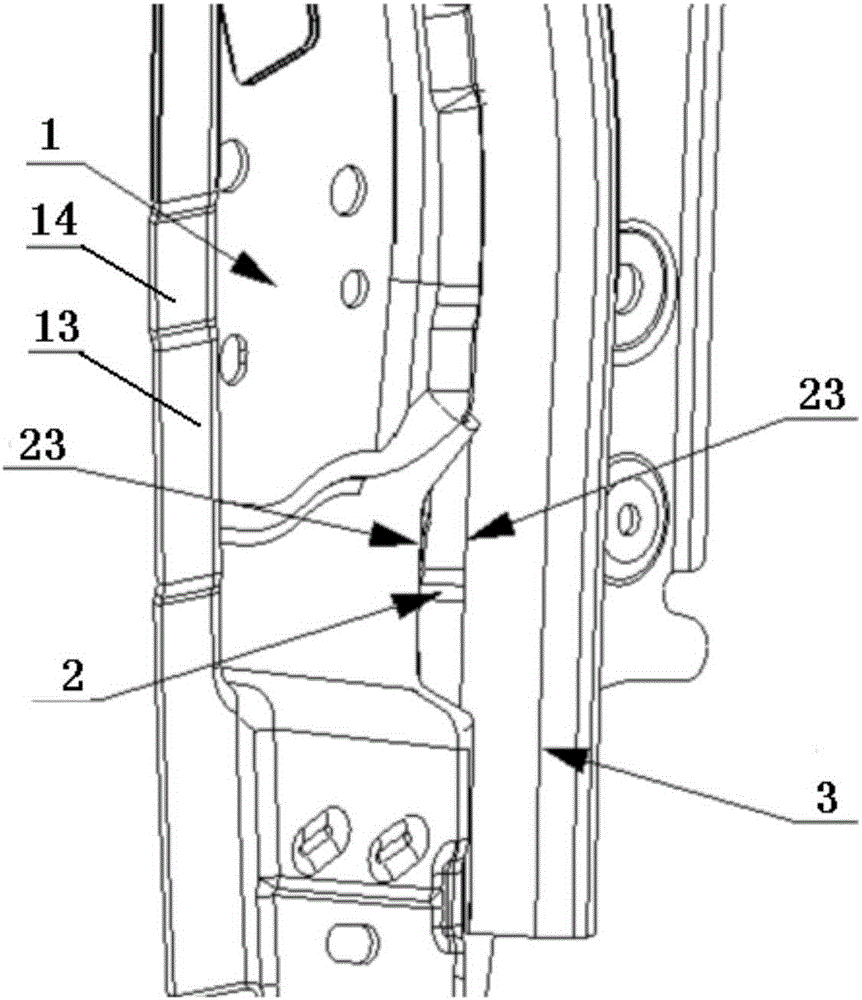

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] see Figure 1 to Figure 6 The rearview mirror mounting structure on a car door shown includes a rearview mirror reinforcement 1, a reinforcement bracket 2 welded to the rearview mirror reinforcement, a door hinge reinforcement 15 connected to the lower left side of the rearview mirror reinforcement, The door hinge nut plate 5 and the door inner panel 6 fixedly connected with the door hinge reinforcement can improve the rigidity of the door window frame and the rigidity of the rearview mirror installation point. The automobile rearview mirror is connected to the above rearview mirror reinforcement by bolts, and its The essential features are:

[0024] The rearview mirror reinforcement 1 is a stamped sheet metal part, the left part is the outer installation surface 16, and the right part is the inner installation surface 13; the mi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap