Compressor heating system and method

A heating system and compressor technology, applied in the field of compressor heating, can solve the problems of easy aging, low reliability of the heating belt, and difficult circuit breaking, and achieve the effect of ensuring the heating effect, ensuring the power, and avoiding the reduction of the current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

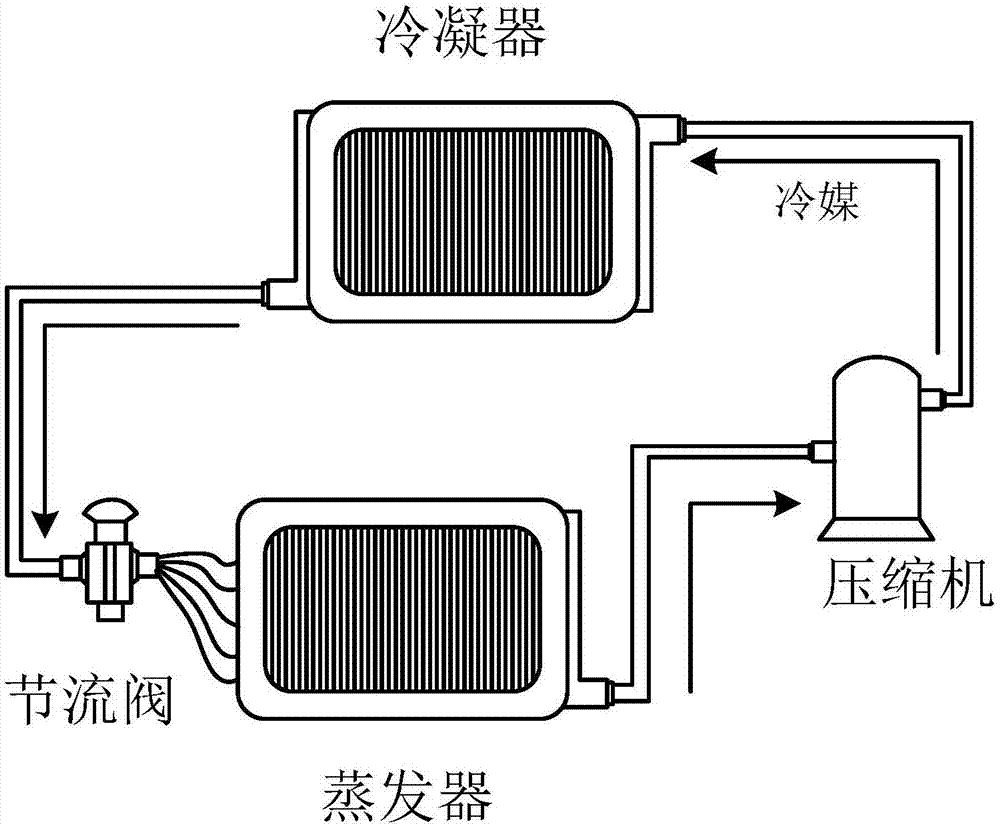

[0068] When the compressor in the air-conditioning system is stopped, the compressor needs to be heated to prevent the liquid refrigerant from flowing into the compressor with a lower temperature. In the existing compressor heating method, a flexible heating belt is usually arranged outside the compressor to heat the compressor body. However, the heating belt has problems such as low reliability, easy aging, and difficult to detect disconnection, and the installation of the heating belt also has the problems of high initial investment cost and high maintenance cost.

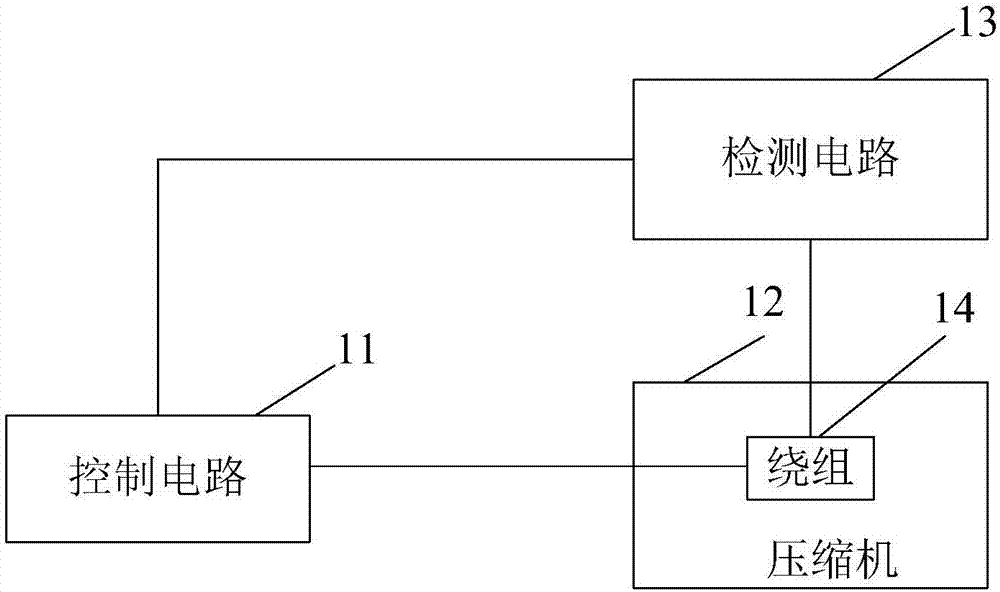

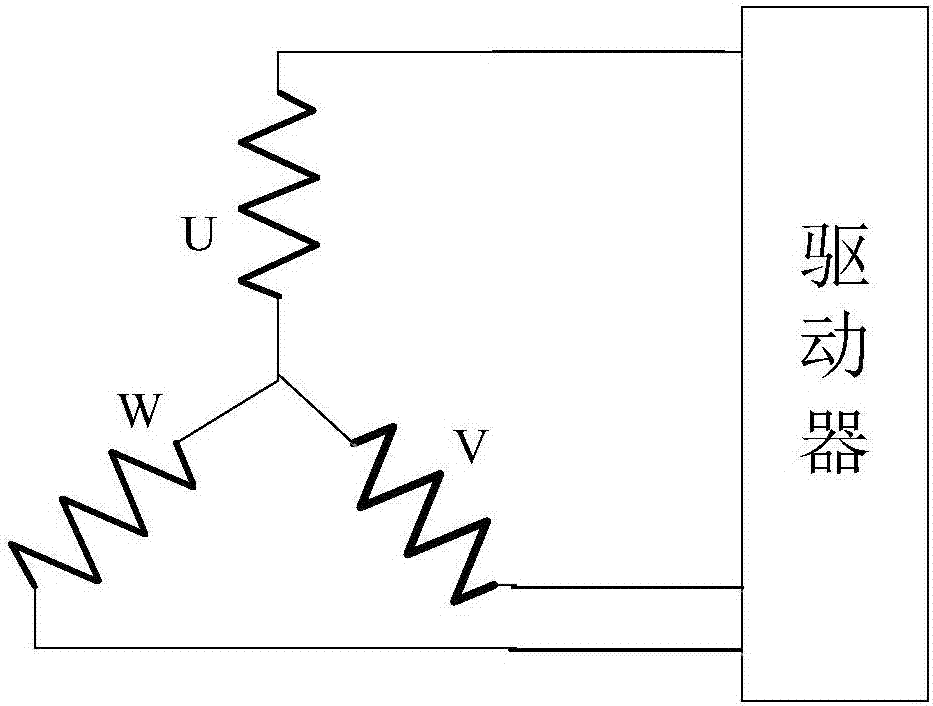

[0069] In order to solve the above problems, the present application provides a compressor heating system and method, which supplies power to the windings in the compressor, so that the windings generate heat to heat the compressor, and a detection circuit is provided to detect the voltage / or current in the windings to indicate the compressor The temperature of the compressor is then determined whether to stop heatin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap