A method and a system for real-time interaction of production information data based on an ERP system

An ERP system and production information technology, applied in the field of ERP system, can solve the problems of poor decision support ability of production managers, prone to errors, lag and backward data update, etc., and achieve the effect of reliable production dynamic information and decision basis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

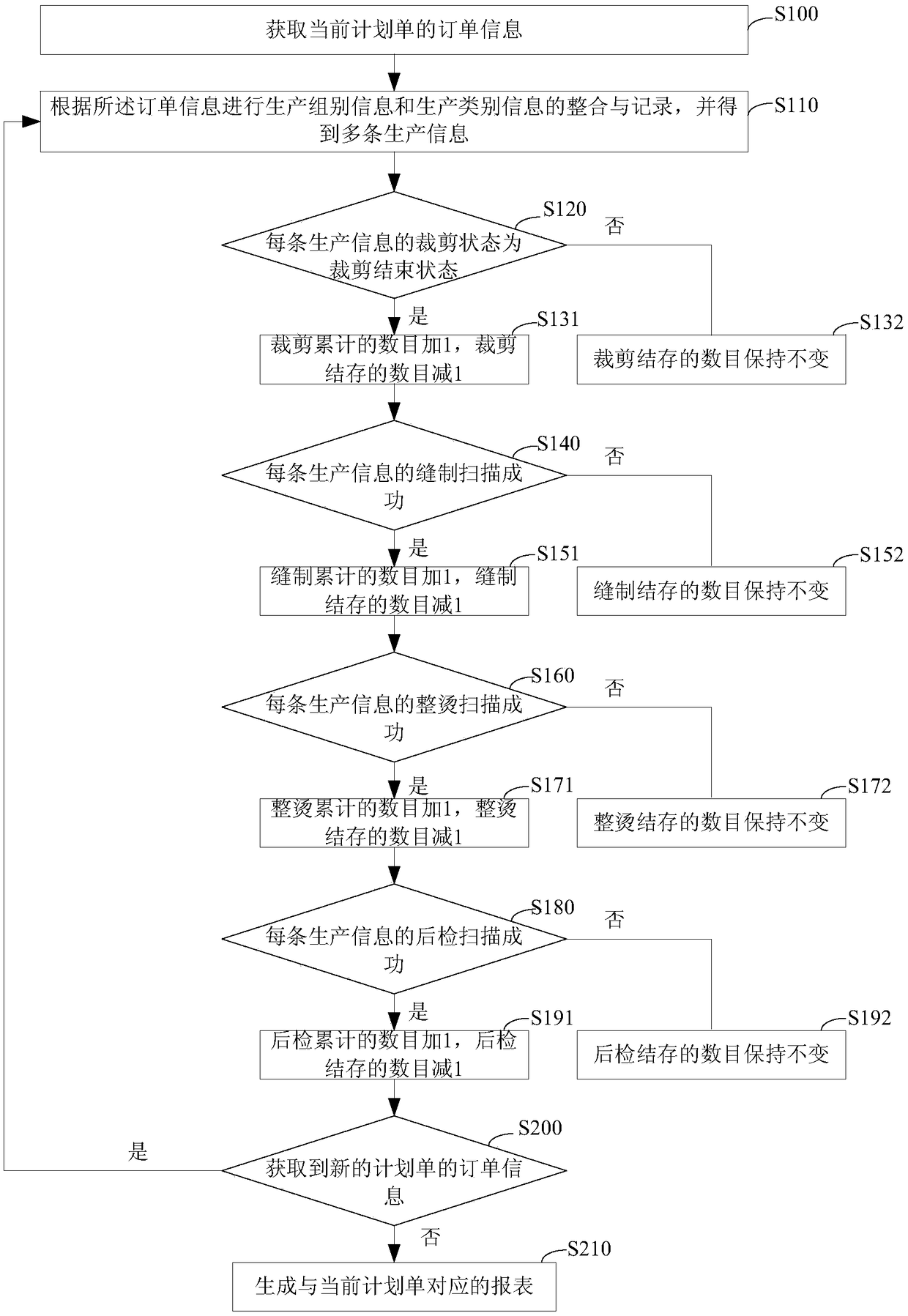

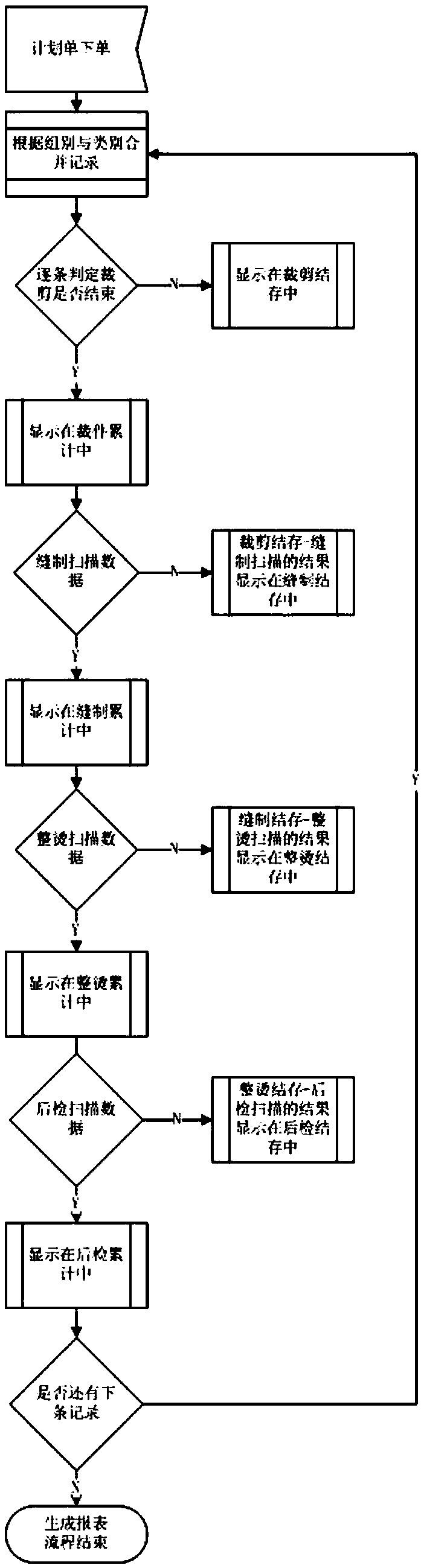

[0039] As a first aspect of the present invention, a method for real-time interaction of production information data in an ERP system is provided, wherein, such as figure 1 As shown, the method for real-time interaction of production information data based on the ERP system includes:

[0040] S100. Obtain order information of the current planning order;

[0041] S110, integrate and record the production group information and production category information according to the order information, and obtain multiple pieces of production information;

[0042] S120, judging whether the cutting state of each piece of production information is the cutting end state;

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap