Method for producing terylene modifier SIPE using composite catalyst

A composite catalyst and modifier technology, used in organic chemistry, sulfonate preparation, etc., can solve the problems of low SIPE product purity and high SIPEDEG content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 A kind of method that composite catalyst produces polyester modifier SIPE

[0032] (1) Feeding

[0033] Add 630 kg of ethylene glycol to the dissolution kettle, start stirring, and add 400 kg of dried three-monomer production wastewater concentrate to the kettle. To 90°C, keep stirring at this temperature for 65 minutes. Open the discharge valve of the dissolution kettle, feed the centrifuge, centrifuge, and recover the sodium sulfate obtained by the filter cloth to obtain an industrial product that meets the national standard; the obtained filtrate is sucked into the synthesis kettle by vacuum to synthesize SIPE;

[0034] In the dried three-monomer production wastewater concentrate, the moisture content is less than 0.2%, the content of dimethyl-5-sodium isophthalate is 30.02%, and the content of monomethyl-5-sodium isophthalate is The content is 7.35%, and the content of sodium isophthalic acid-5-sulfonate is 22.64%. The rest is sodium sulfate and a small

Embodiment 2

[0047] Embodiment 2 A kind of method that composite catalyst produces polyester modifier SIPE

[0048] Process operation parameter is identical with embodiment 1, and difference is:

[0049] The amount of catalyst added is changed to 3000 grams of calcium acetate, 480 grams of dibutyltin oxide, 330 grams of cobalt acetate, and the amount of anti-ether agent added is changed to 240 grams of sodium acetate, and the rest of the operations are the same;

[0050] Judgment of the reaction end point: when the total amount of methanol in the metering methanol receiving tank and the water in the water receiving tank reaches 43.9 kg, it means that the esterification is about to end.

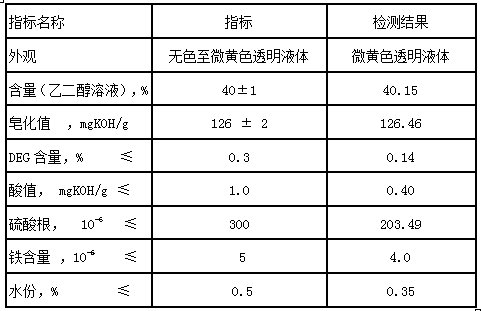

[0051] Analysis results: the content of SIPE in the solution was 40.16%, and the test results of other indicators are shown in Table 2 below.

[0052] Table 2

[0053]

[0054]The yield of SIPE is: 77.19%; the time of SIPE synthesis reaction (referring to the time from the time when the dried concentrate

Embodiment 3

[0055] Embodiment 3 A kind of composite catalyst produces the method for polyester modifier SIPE

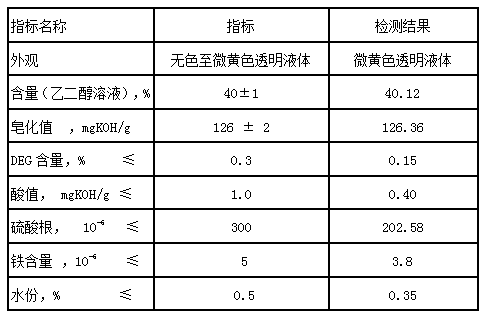

[0056] (1) Feeding

[0057] Add 575 kg of ethylene glycol to the dissolution kettle, start stirring, and add 370 kg of dried three-monomer production wastewater concentrate to the kettle. To 90°C, keep stirring at this temperature for 65 minutes. Open the discharge valve of the dissolution kettle, feed the centrifuge, centrifuge, and recover the sodium sulfate obtained by the filter cloth to obtain an industrial product that meets the national standard; the obtained filtrate is sucked into the synthesis kettle by vacuum to synthesize SIPE;

[0058] This batch of dried three-monomer production wastewater concentrate has a moisture content of less than 0.2%, a content of dimethyl isophthalate-5-sodium sulfonate of 28.33%, monomethyl isophthalate-5-sulfonate The content of sodium sulfate is 9.94%, the content of sodium isophthalic acid-5-sulfonate is 23.05%: the rest is sodium sulfat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap