Method for improving recycling efficiency of dyeing residual liquid

A technique for dyeing residue and dye liquor is applied in the field of improving the recycling efficiency of dyeing residue, and achieves the effects of simple calculation, simple preparation method and improved recycling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

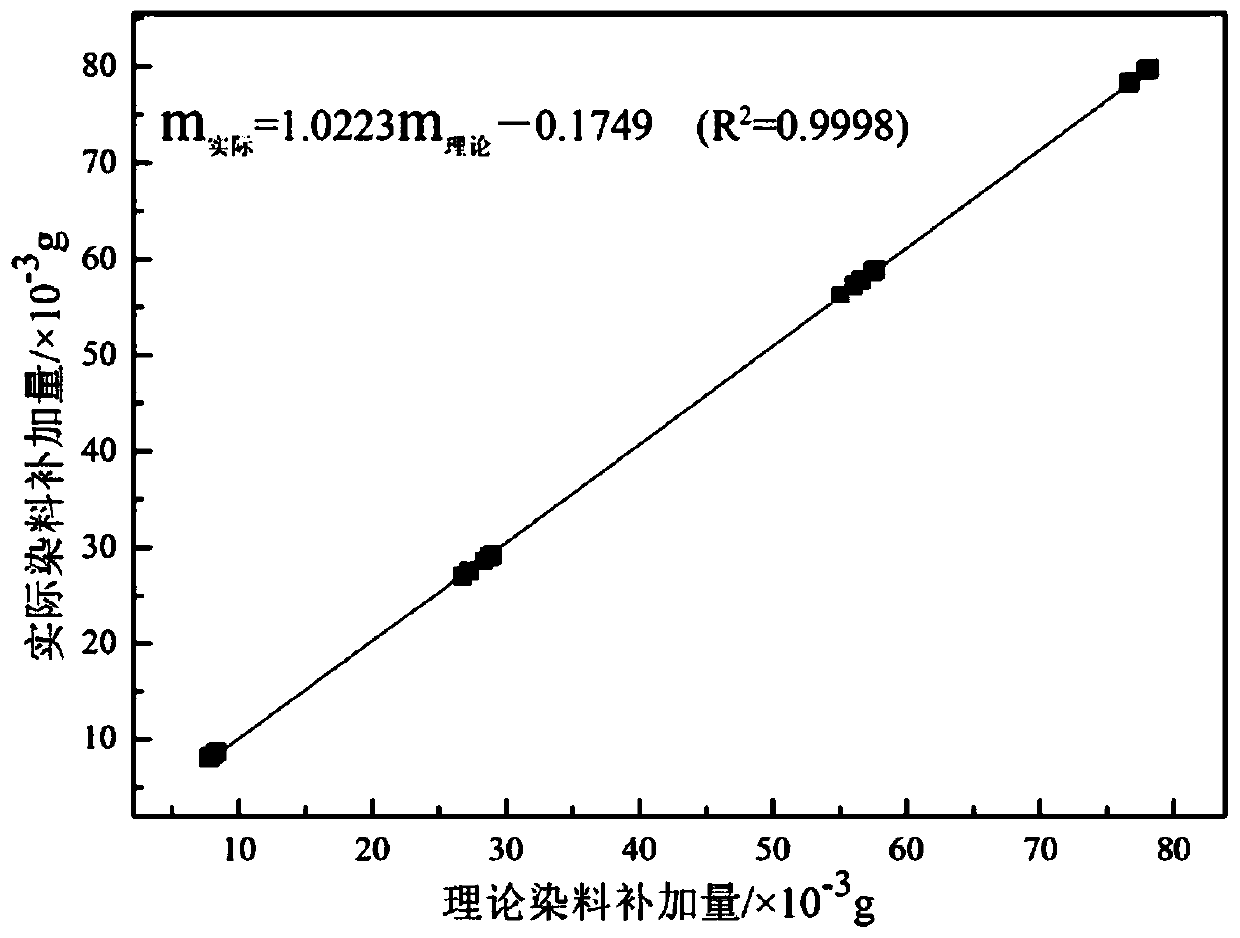

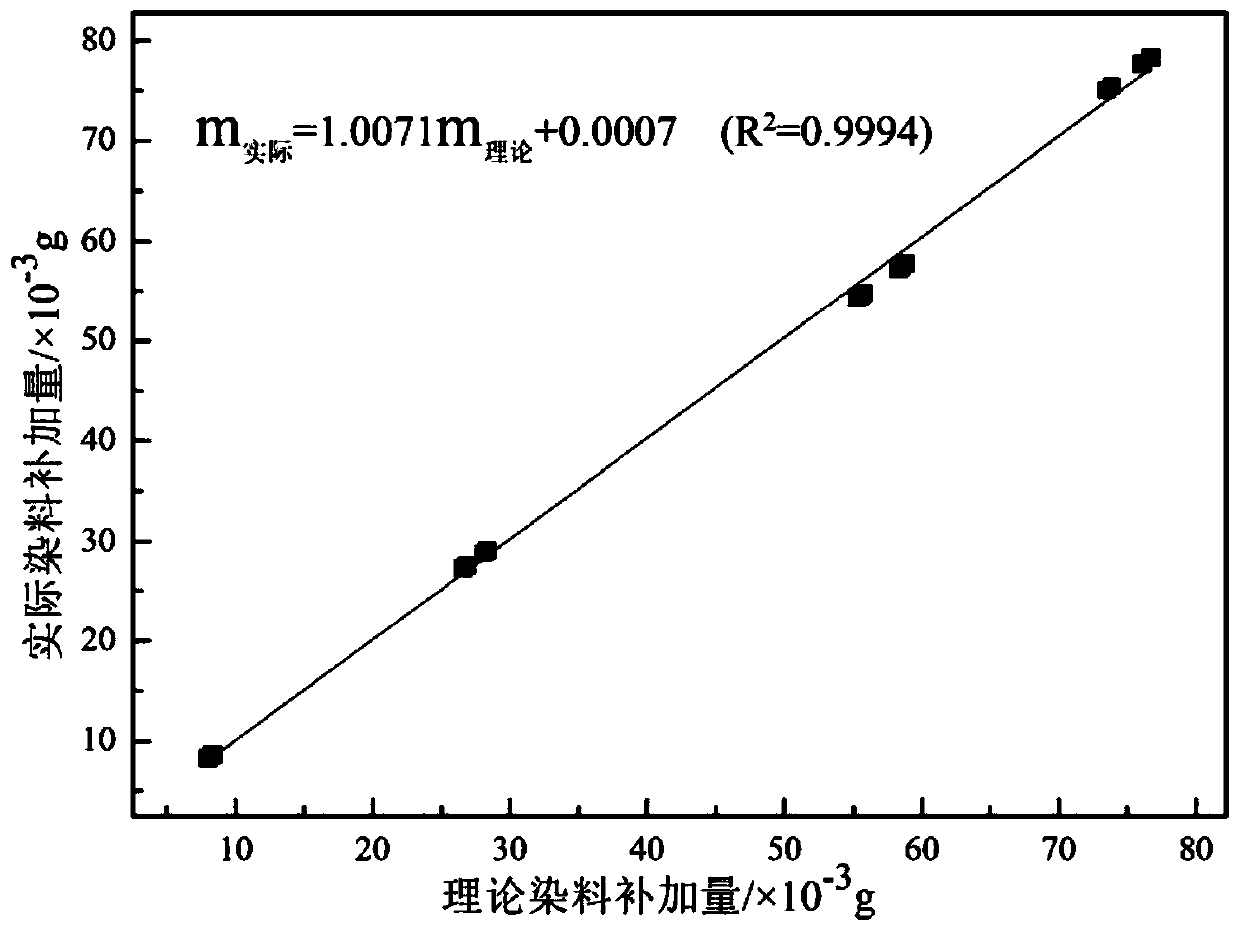

[0041] Acidic black single-component dye solution, the concentration is 0.02g / L, 0.03g / L, 0.04g / L, 0.05g / L, 0.06g / L, 0.07g / L, 0.08g / L, 0.09g / L, 0.10g / L, collect the solution ultraviolet-visible absorption spectrum, adopt the peak area method to establish the calculation relationship between concentration and peak area: (peak area) S=584.04*C-1.260. Configure 0.01 to 0.08g / l black dye for dyeing, and adjust the amount of dye added after the dyeing effect is verified. 实际 , build m 实际 with m 理论 relationship such as figure 1 shown. After creating a reuse, m 实际 with m 理论 relationship such as figure 2 shown. During factory production, nylon fabric is 200kg, bath ratio is 1:20, black dye consumption is 2% o.w.f. (the ratio of dye to fabric weight), after dyeing, the absorption spectrum of dyeing residue is collected, and the calculated theoretical consumption of dye is 3.64kg, according to The formula calculates that the actual amount of dye used is 3.55kg.

Embodiment 2

[0043] Prepare B sauce red, 2R yellow and PA-01 navy blue single-component dyeing solution, the concentration is 0.02g / L respectively,

[0044] 0.03g / L, 0.04g / L, 0.05g / L, 0.06g / L, 0.07g / L, 0.08g / L, 0.09g / L, 0.10g / L, shake the solution well for testing. The ultraviolet-visible absorption spectrum of the solution was collected, and the calculation relationship between the concentration and the spectrum-derivative absorbance photometry was established by using the zero-crossing point ratio spectrum-derivative absorbance photometry, as shown in Table 1:

[0045] Table 1 Zero-crossing ratio spectrum-derivative absorptiometry standard linear equation value

[0046]

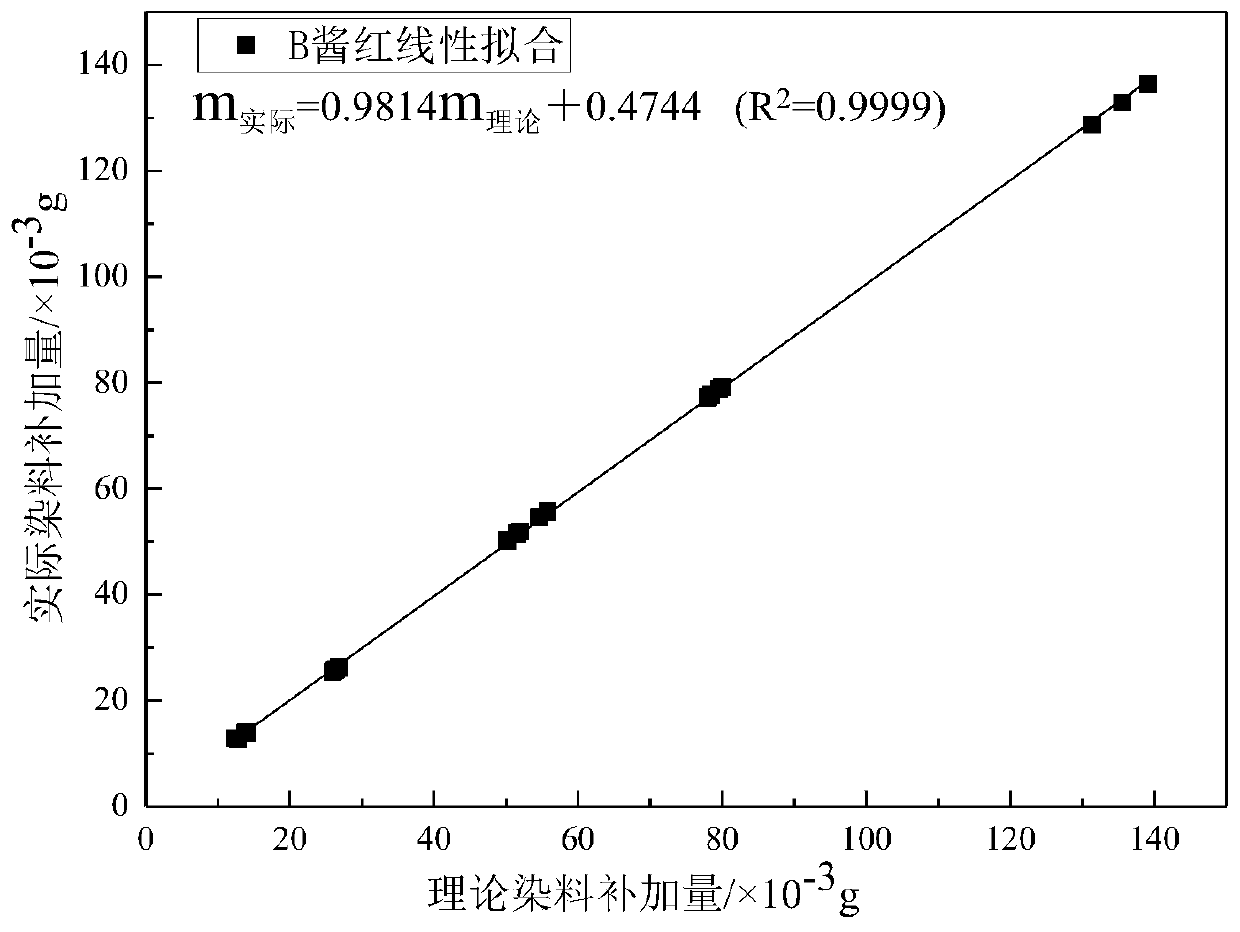

[0047] Configure three kinds of dyeing solutions with different total concentrations of dyes, among which, the mass ratio of the three components of B sauce red, 2R yellow and PA-01 navy blue is 1:2:1. After the dyeing effect is verified, adjust the amount of dye added m 实际 , build m 实际 with m 理论 re

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap