Method for measuring vertical and horizontal offset of positioning line

A measurement method and line technology, applied in measurement devices, measuring instruments, surveying and navigation, etc., can solve problems such as long formulas, difficulty in adapting to calculation requirements, and inability to directly determine the vertical and horizontal accuracy of design lines, so as to improve work efficiency and reduce Construction cost, strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

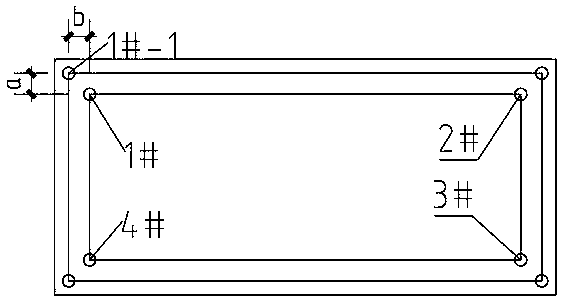

[0032] The present invention is realized through the following technical solutions, as figure 1 As shown, a method for measuring the vertical and horizontal offset of a positioning line specifically includes the following steps:

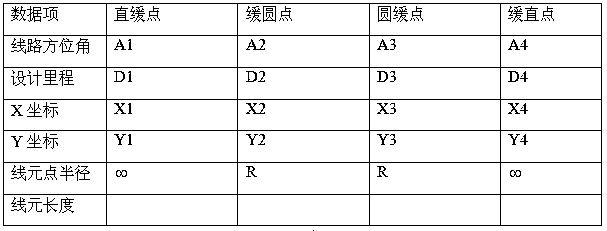

[0033] Step S1: Determine the calculation mileage of the design coordinates of the anchor point, the line direction coordinate azimuth, and the offset distance and deflection angle relationship between the anchor point and the mileage point when the anchor point deviates from the line design line; obtain line element calculation element data.

[0034] After receiving the technical disclosure, review the plane geometric relationship between the positioning point and the mileage point of the line design line against the drawings, and accurately determine the design coordinates of the positioning point and the calculation mileage of the line direction coordinate azimuth angle. When the positioning point deviates from the line design, the positioning point a

Embodiment 2

[0045] This embodiment is further optimized on the basis of the above embodiments, such as figure 1 As shown, further, in order to better realize the present invention, the step S3 specifically refers to: the line element starting point line direction coordinate azimuth, starting point mileage, starting point coordinate value, line element starting point radius, line element end point The radius and line element length are input into CASIO FA-124 in turn, and the integral formula is deduced through the transition curve to obtain the coordinates of the anchor point and the azimuth angle of the line direction coordinates of the anchor point.

[0046] Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

Embodiment 3

[0048] This embodiment is further optimized on the basis of the above embodiments, such as figure 1 As shown, the step S4 specifically refers to: check the instrument and the base before the measurement, check whether there is any change in the instrument, the optical plummet of the base, and the leveling tube, and input the temperature and air pressure measured on site in a timely manner after the instrument is installed. , where the minimum degree of air temperature is 0.2°C, and the minimum degree of air pressure is 2hpa; after correcting the measurement accuracy of the total station and measuring the coordinates of the backsight point, it is still necessary to measure the coordinates of at least one control point for verification, and the measurement can only be carried out after the coordinates are correct. .

[0049] Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap