Industrial equipment surface defect fault early warning method based on edge calculation

A technology for industrial equipment and fault early warning, applied in the field of fault early warning of industrial equipment surface defects based on edge computing, which can solve the problems of difficult to obtain performance detection models, less fault data, and difficult to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

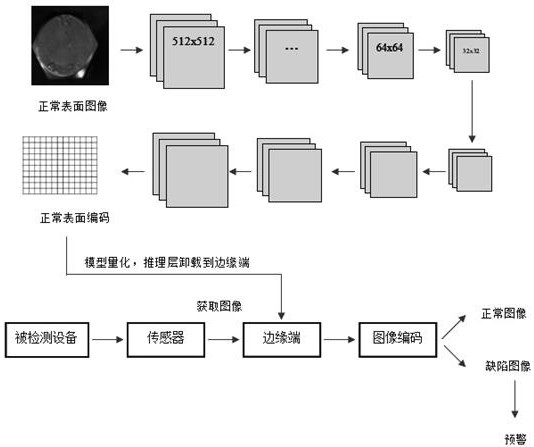

[0019] An industrial equipment surface defect failure warfront based industrial equipment, including the following steps:

[0020] (1) Build a data set: acquire the normal image data of the normal image data to be detected; image data;

[0021] (2) Grayness and normalize the input data;

[0022] (3) Enter the coding method of the normal image;

[0023] (4) Complete the training of images;

[0024] (5) Uninstall the reasoning task to the terminal and determine the real-time data acquired by the sensor.

[0025] like figure 1 As

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap