Method and system for detecting single-plate on position

A detection method and single-board technology, which is applied to the detection of faulty computer hardware, measuring electronics, measuring devices, etc., can solve the problems of inability to use single-board on-site detection, large number of backplane buses, etc., and achieve reliable on-site detection , the effect of reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

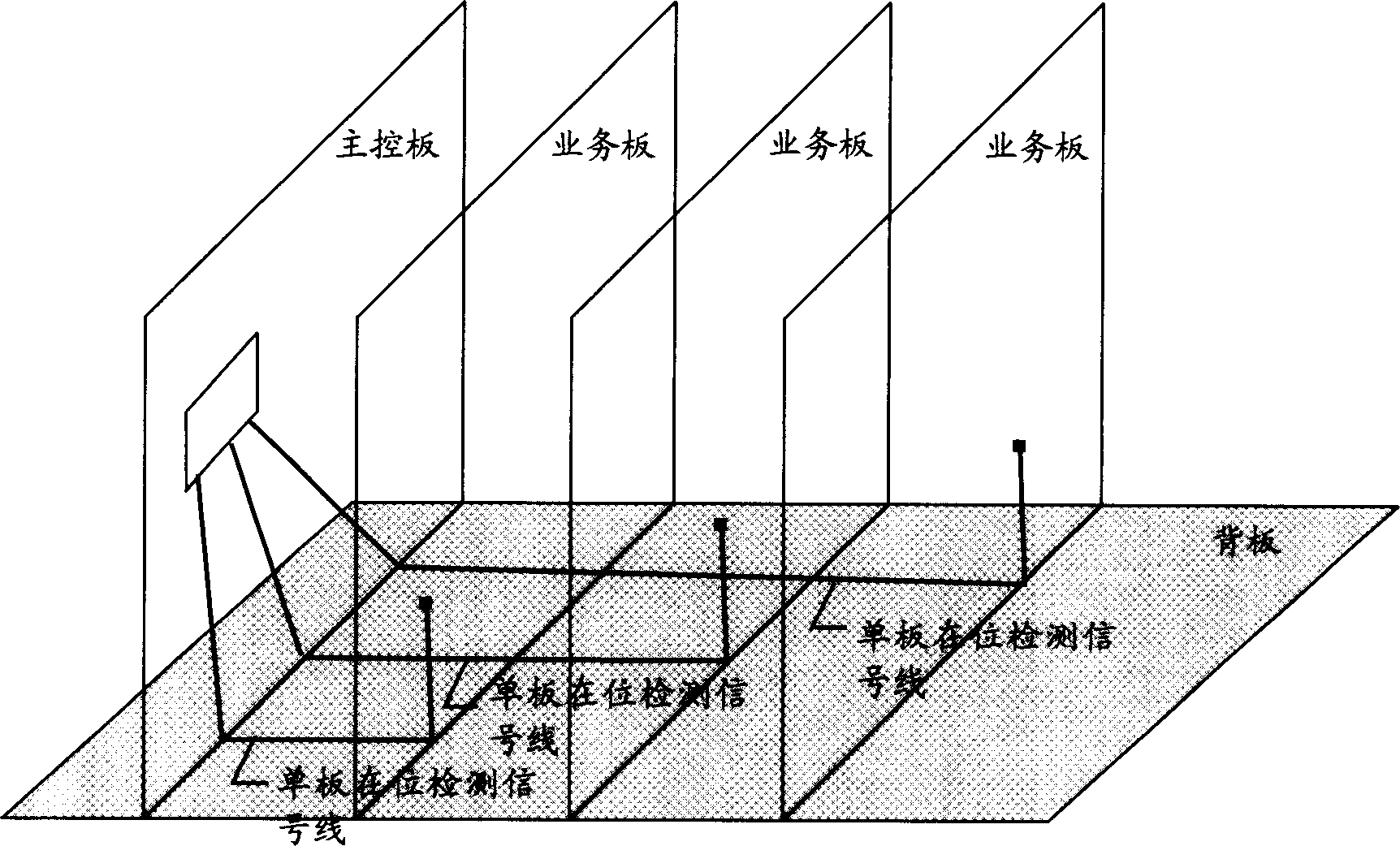

[0046] JTAG (Joint Test Action Group, Joint Test Action Group) formulated the boundary scan test specification, and became the IEEE standard IEEE1149.1-90 in 1990, referred to as the JTAG standard. The JTAG standard has greatly promoted the development and wide application of boundary scan technology. . Now the application of boundary scan technology is becoming more and more common, the main applications are board interconnection test, FLASH loading, logic programming and so on. The application level also develops from the chip level to the circuit board level and then to the system level, and various application characteristics are continuously excavated. The following board presence detection method of the present invention uses the boundary scan technology to realize the board presence detection.

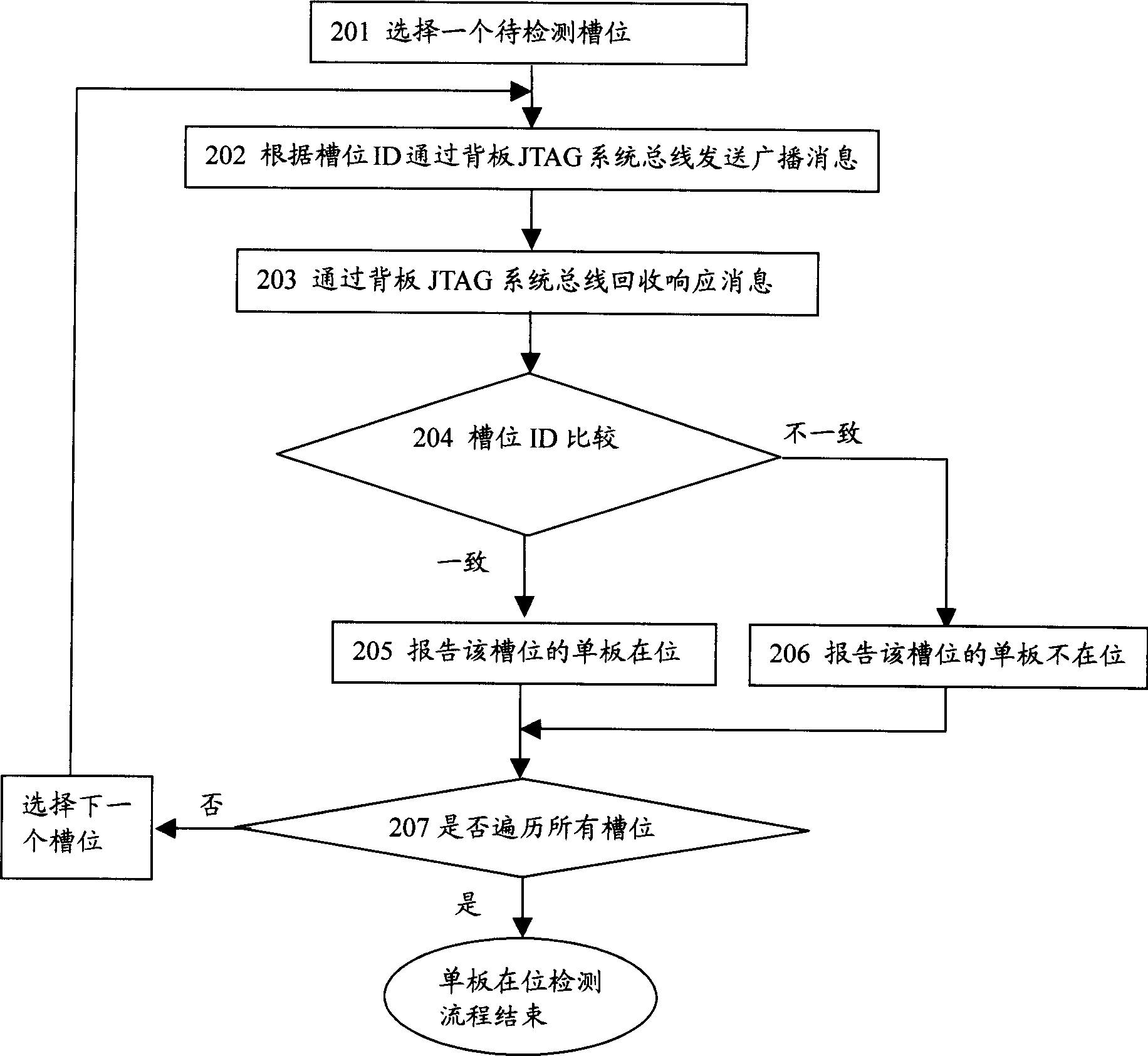

[0047] Such as figure 2 As shown, the veneer presence detection method of the present invention comprises steps:

[0048] Step 201, the network management or the test terminal

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap